Back in ancient times, warriors used special steel helmets to protect their heads. They were equipped with the legionnaires Julius Caesar, the Scythians, medieval knights in Europe. The steel helmet received its widespread use in Kievan Rus, in which it was represented by a wide variety of species.

Nowadays, hats that protect during battles are no longer called a steel helmet. Today this name is not used. Modern helmets are known to consumers as helmets. The military makes up the main percentage of all users of this type of headgear. In addition to them, helmets are used by miners, builders, police, firemen and participants in extreme sports.

How did the concept of "helmet"?

A special piece of clothing designed to protect the warrior's head during a battle was originally called a helmet. Since it was a continuation of the armor and was also made of iron, the military command introduced it into a standard combat kit under the official name “steel helmet” and was recognized as an effective means of individual protection of a fighter.

With the advent of various types of troops and the improvement of military craft, helmets began to be modernized. Products had a domed shape. Steel was used for their manufacture. But history knows samples made of felt and leather, the protective properties of which were provided by a large number of metal elements attached to them. Due to the presence of these steel parts, the headgear was associated with iron. Over time, a more convenient word “helmet” appeared in everyday life, which in Latin means “metal helmet”.

Helmets

Helmets of the war years have always been the subject of research by historians and archaeologists who have thoroughly studied all the features of the structure and form of personal protective equipment soldier, widely used for more than one thousand years. Scientific studies give reason to believe that the main part of the construction of a protective helmet for many centuries remained unchanged. Changes affected only the form. She depended on the development of weapons and weapons, from which she was obliged to protect.

As the material for the manufacture of helmets, metal was used. These were thin sheets of bronze or copper, which over time were replaced by steel or iron. It was helmets made of iron sheets that were used by all armies of the world until the 80s of the twentieth century. Later, military helmets and helmets began to be made of such modern materials as titanium, Kevlar, fabric polymers, and the combination of titanium with aluminum.

The internal structure of the helmet is represented by a special leather part, fastened with rivets around the circumference in the lower inner part of the product. This part of the helmet was called “tuleika”. It branches with slots into several petals connected by a cord. The main functions that Tuleika and petals perform:

- ensuring a balanced landing helmet on the head;

- prevention of contact of the head with the metal sheet of the helmet;

- softening the impact of shrapnel and stones on the outside of the helmet.

Modern military helmets are more comfortable and safer for a soldier, since the petals contain additional pads made of foam or leather that strengthen the softness.

Fashion influence

From the time of the legionnaires Julius Caesar to the European knights of the Middle Ages, soldiers actively used helmets. The military operations of those years were carried out with great intensity, and the demand for protective hats was especially great. But over time, helmets began to fulfill an aesthetic function. There was a fashion for beautiful hats. The security issue has faded into the background. The helmets were replaced by hats with feathers, shakos and caps with beautiful lacquered visors.

French helmet

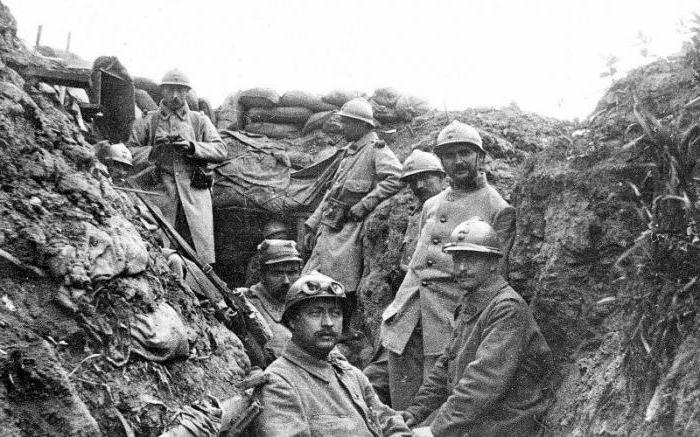

Military operations in the First World War were trench in nature. The targets were the unprotected heads of soldiers. Careless movement along the trench threatened with serious injury or death. An uncovered head was a vulnerable spot for rifle or machine gun fire, for shrapnel and land mines. For the first time in these years, they again remembered the high performance of helmets. By this time, the fashion for beautiful hats and shakos had passed, and helmets returned to service.

The military of France were the first to be equipped with new, more advanced models. French products contained three elements: cap, skirt and comb. “Adriana” - such an official name was given to these helmets. Since 1915, the military French were equipped with these protective products, which significantly reduced the loss of army personnel. Mortality decreased by 13% and the number of wounded decreased by 30%. During the First World War, French helmets were used by soldiers from England, Russia, Italy, Romania and Portugal.

English helmet

The military leadership of England was not satisfied with the French helmet "Hadrian." It was decided to create your own version of a military helmet. The developer of this protective product was John Leopold Brody, who took the medieval Capellin hat, widely used by the military from the eleventh to sixteenth century, as the basis. The helmet was called the “helmet of the steel of the first modification” and was a one-piece stamped product with wide brim.

This form of helmet was very convenient for trench battles, because the fields created the effect of an umbrella for a soldier, sheltered from shrapnel falling from above. But this model was inconvenient when it was necessary to attack, since its landing on the head was carried out very high and did not completely protect the temporal and occipital parts of the head. But, despite this drawback, Brody's English helmet was adopted by the armies of Canada, the United States of America and Australia.

German version of the helmet

Unlike other countries, Germany until 1916 did not spend money on the production, according to its experts, of low-quality low-grade helmets. Her gunsmiths in Hanover were engaged in the construction of truly high-quality products. In 1916, Germany saw the famous Stahihelm helmet, which later became a symbol of the German soldier, as it was used in two world wars.

The German helmet was significantly superior in comfort and protective qualities to the French and English models. A characteristic design feature in the Stahihelm helmet was the presence of steel horns in the temporal regions. They performed several functions:

- provided cover for ventilation holes in the helmet;

- carried out fastening of a special armored shield protecting the head of a German soldier from direct hits of rifle and machine-gun bullets.

Despite the absence of flaws in the design and form, the German version of the helmet did not guarantee the absolute safety of personnel. Although the helmets could withstand direct bullet hits, they did not ensure the safety of the soldier's cervical vertebrae. Impacts when hit in a helmet had such high energy that the cervical vertebrae were injured. And this, in turn, entailed a fatal outcome. The improvement in this situation was not affected by the fact that the energy of the blows during direct hits was calmly kept by the helmet itself.

Soviet military model

For the production of helmets in the USSR, alloyed armor steel was used. The Soviet model was called the SSH-39 and was a product weighing 1.25 kg. The walls had a thickness of 1.9 mm. Helmet tests were carried out personally by S. M. Budyonny and gave a good result. The Soviet model was able to withstand direct hits from a distance of ten meters from the Nagan revolving bullet.

In 1940, the SSH-39 was modernized. The tulle was equipped with additional belts, nets and lining. SSH-40 - such an official name was given to an advanced helmet. Subsequent changes and innovations were made in 1954 and 1960. The result was the appearance of new helmets SSH-54 and SSH-60, the changes in which affected only the tulles. The design itself has remained unchanged since 1939.

Advanced SS model

Substantial refinement of the SSH-39 was made in 1968. The form that the helmet had was subject to modernization. The Russian military model now had an increased tilt of the frontal wall of the dome and shortened curved sides. For its manufacture, an armor alloy with greater strength was used. The inclination of the frontal wall enhanced the helmet's resistance to fragmentation.

A similar helmet design is used by China, North Korea, the Russian Federation, India and Vietnam to equip their personnel.

Some of the most effective military helmets used by the power structures of Russia are:

- SSh-68 M is intended for internal troops;

- SSH-68 N is used by the armed forces of the Russian Federation.

Both options have modern tulles. Despite the fact that the weight of these helmets is about two kilograms, they correspond to the first resistance class, since they are able to withstand direct bullet hits from a Makarov pistol and fragments flying at a speed of 400 m / s, the mass of which does not exceed one gram.

Modern Russian helmet

Helmet STSh-81 “Sphere”, since 1981, and to this day is used by the internal troops of the Russian Federation.

A 0.3 cm thick titanium plate was taken to manufacture its body. The helmet weighs 2.3 kg and is used only for protection against mechanical injuries. It meets the second class, since it does not guarantee protection against firearms. The design of the dome is three armored elements that are contained in special covers.

The helmet “Sphere” has the modification “Sphere-P”, in which titanium armored plates were replaced with steel, which significantly increased the weight of the model (3.5 kg). A drawback in the design is the lack of its integrity. Head injuries are possible. Special covers with armored titanium or steel elements wear out quickly. This leads to their displacement and lowering the protective qualities of the helmet.

How to make a military helmet?

First of all, you need to acquire the necessary materials. The second step is to make a drawing according to which a military helmet will be created. It is not difficult to make it with your own hands. It is better if the helmet will have a spherical shape. This will reduce destructive energy upon impact. A well-made lining will also help absorb it or significantly reduce it.

The basis for the helmet can be a blank of wood or a children's ball treated with gypsum binders and epoxy resins with a hardener. After hardening of gypsum, the frame is considered ready, and the blank can be removed.

One of the tasks that the helmet performs is to redistribute the shock over its entire area. Therefore, the material for the outer shell must have a high rate of strength and viscosity. Polyurethane foam is ideal. Its tensile strength is 5 kg / cm 2 , which makes it very effective in absorbing shock. You can use fiberglass, which in several layers is glued to the surface of the helmet and coated with epoxy. After the resin has hardened, the excess is removed with a spatula, and the remaining fiberglass is cut with a knife.

The inside of the helmet must contain foam blocks, which increases protection against impacts. They are attached with glue. This is recommended after a careful fit. It is important that there are no voids in the inside of the helmet, foam blocks should not press on the temporal region.

Blocks in the occipital and frontal parts are glued last. They prevent possible helmet displacement from impact. If there are voids in the helmet, they are filled with pieces of PPU. Before proceeding with gluing the inside, special fastening straps are mounted with screws and washers.

The final touch will be painting a homemade helmet. To do this, you can use aerosol nitro paint or nitro enamel. But before that, the surface of the product must be treated with an automotive nitro primer.

The disadvantages of homemade helmets are the lack of heat transfer and poor sound permeability.

Before you begin to work, you need to understand that the helmet does not guarantee the safety of the head, it only softens the blow. In addition, impact force is essential. The energy generated in this case is approximately 25 J. This is the person’s endurance limit, exceeding it threatens with loss of consciousness and more serious consequences.