The MTZ-82 model tractor has been produced by the Minsk plant for many years. Due to its reliability and versatility, the machine has become very popular in all CIS countries and abroad.

General information

The design of the tractor uses a four-cylinder diesel engine and multi-speed gearbox. A clutch assembly is installed between these units, which needs regular maintenance. Adjustment of the clutch on the MTZ-82 allows you to ensure compliance with the power and traction performance of the tractor factory documentation. The operability of the equipment depends on the correctness of the set gap in the mechanism, since when the clutch wears, its slipping begins, which causes more and more rapid wear of the assembly.

Freewheel detection

Checking and adjusting the clutch on the MTZ-82 tractor should be carried out after 125 hours of operation of the machine in any conditions. To measure time, a special engine hour meter is used, located on the instrument panel in the cab.

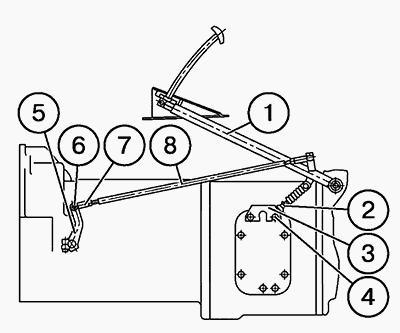

Before starting work, measure the pedal free wheeling to drive the clutch mechanism. Between the pedal and clutch levers there is a long rod mounted on the fingers. Under normal conditions, the clutch lever should move following the movement of the pedal to a distance of not more than 7 mm. This distance is measured by the radius of the finger. With this mobility of the lever, the pedal’s free play is from 40 to 50 mm.

Typical Malfunctions

One of the most common problems is the incomplete supply of torque from the engine flywheel to the wheels. The reason for this may be the lack of free play on the pedal, which should be set when adjusting the clutch on the MTZ-82. With an increased stroke, the friction discs are not fully retracted, which causes difficult gear shifting. A characteristic sign of such a problem is the grinding of gears when shifting.

The owner and driver of the tractor must remember that the operation of equipment with an unregulated clutch will lead to breakdowns of many nodes and costly repairs. In addition, the equipment will be idle, which is unacceptable if urgent work is necessary (for example, during harvesting or sowing).

Settings

If the values exceed these parameters, it is necessary to adjust the clutch on MTZ-82. To do this, follow these steps:

- Remove the link that connects the pedal and clutch lever. To do this, take out the connecting finger mounted on the clutch assembly.

- Using the screw adjuster, lower the pedal to its lowest position until it stops in the cab floor. To do this, the regulator screw must be unscrewed.

- Push the release bearing against the surface of the release levers and hold the parts in this position. This is done by turning the clutch control lever counterclockwise.

- Using a screw connection on the rod, bring its length to the coincidence of the holes at the end of the rod with the hole of the designated clutch lever.

- By reversing the rotation of the joint, slightly reduce the length of the link. The screw is turned 4.5 ... 5 turns, but no more.

- Connect the link and the clutch lever with your finger.

- Check pedal travel by measuring against a thrust pad.

If it is not possible to carry out the adjustment by the indicated method and if the free play is too small, the release levers must be adjusted. To do this, you need to separate the engine and gearbox and set the position of the levers using a special tool - a mandrel. It is installed on the internal splines of the clutch support element and abuts against the support part itself with an end surface. Then, by rotating the nuts, a uniform stop of the levers on the end part of the mandrel is achieved. The nuts are locked in position with special washers. The aim of the adjustment is to set the required clearance of 13 mm between the levers and the support element.

After that, you should check the correct operation of the mechanism that returns the pedal to the upper position. This device should provide a quick and reliable return pedal from its lowest position. If the pedal is not fast enough, additional adjustment of the MTZ-82 clutch should be carried out. The tips for adjusting the mechanism are as follows:

- Loosen the fastening bolts of the lower spring return bracket.

- Turn bracket itself clockwise.

- If the bracket does not have the ability to rotate, then tighten the adjustment bolt located on the spring. The amount of adjustment should ensure uninterrupted return of the pedal to the upper position.

- Tighten all loose screw connections.

New type clutch

On machines of the last years of release, nodes with a modified design are used. The general steps for adjusting the MTZ-82 clutch of a new sample have not changed. Only the gap between the levers and the support has changed, which should lie in the range from 11.5 to 12.5 mm.