If you will be able to equip your own spiral staircase with your own hands, the drawing must first be prepared, this will allow you to carry out the work, avoiding errors. A feature of this design is the fact that the steps are strengthened radially. This applies to the real or imaginary center. If you project a staircase to the floor surface, you can get a polygon or circle. A spiral staircase can be made of metal with your own hands, drawings should definitely be considered before this. Choosing such designs, you may prefer one of the varieties of the system. Thus, the steps can be supported on the central pillar and on the surface of the walls around the perimeter. They can be mounted in other versions only on the support post, which is located in the center. The steps in some cases rest on a fence or bent bowstrings, among other things, they can be pinched in a support stand.

Manufacturing Features

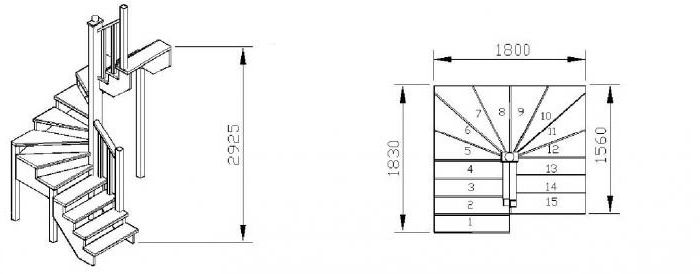

If a spiral staircase is built with your own hands, the drawing will allow you to carry out the work correctly. You can borrow one or another option from this article. Such structures occupy a small space, for example, with a step width of 1 meter, the diameter of the structure will be 2.2 meters, the central support is also included here. In fact, the structure will occupy less than 2 square meters on the floor surface. By designing a product, you can give it a different angle of inclination, most often it does not exceed 45 degrees.

What you need to know before starting work

If a spiral staircase is to be made with your own hands, a drawing must be prepared by you before the start of work. However, it is important to consider that such structures do not have very wide steps, this indicates that movement along them will be difficult, it is important to be careful. It will be quite problematic to miss two people who meet on a spiral staircase. It is also very difficult to move dimensional objects on it. This suggests that it is more rational to use screw structures in those rooms in which there is no heavy traffic. A lot of effort will have to be made to manufacture, since the elements and assemblies are more complex if compared with conventional ones.

Preparation of materials

If you will make a spiral staircase with your own hands, you can consider the drawing for it by reading this article. However, it is equally important to get acquainted with the technology of the process and prepare all the necessary materials. It is not necessary to limit the choice of material: hardwoods are suitable , among which maple, beech, and oak can be distinguished. You can stock up on profiled or sheet metal.

Stair design

The design should be deprived of the riser, which is a vertical element located between adjacent steps. This will prevent slipping legs when moving. The step in the middle should be 20 cm or more. Admittedly, quite often today spiral staircases are made with their own hands. Drawings, photos will help you determine the choice of design features. In order to ensure the reliability of the attachment point of the steps, the diameter of the middle support post should be five centimeters or more. The height between the branches should exceed the height of a person, this indicator is equivalent to two meters or more. In this case, you do not have to bend when using the lifting mechanism. As for a complete turn, then it should have at least 12 steps.

Features of the calculation

Before making spiral staircases with your own hands, drawings are prepared by masters, this allows you to exclude many errors, which can be very difficult to cope with. You can take as a basis the parameters that are presented below.

The height of the floor, which is measured from the surface of the floor of the first to the base of the floor of the second floor, is equivalent to 3 meters, while the width of the stairs is one meter. The diameter of the rack in this case is equivalent to 20 cm. Now you can determine the diameter of the structure. This figure will be made up of the diameter of the support column and two steps, or rather, their width. Thus, the following calculations will need to be performed: 2x1.0 + 0.2. In the end, it will be possible to obtain a value of 2.2 m.

When spiral staircases are made with their own hands, drawings are prepared by home craftsmen, as a rule, on their own. Having determined the diameter of the structure, it is necessary to draw a circle. At the next stage, the radius of the trajectory of movement is calculated. For this, it is necessary to divide by 2 the diameter of the support column, to which the step width should be added. The calculation will look as follows: (1 + 0.2) / 2; the required value is equivalent to 0.6 m.

The next step will be the calculation of the number of steps, which will occur in 1 turn. To do this, the length of the trajectory must be divided by the width of the step. The final value is 18.84, while the calculation is as follows: 2x3.14x0.6 / 0.2.

If you are going to make a spiral staircase to the second floor with your own hands, it is important to determine the height of the step. The height of the coil should be divided into 19 parts. The step between the first step and the last step of the turn should be greater than the height of the person. You can take into account a figure equal to two meters, you need to add 5 cm to this value, this will allow you to get the height of the turn, the calculation at the same time looks like this: 2 + 0.05; as a result, a value of 2.05 m is obtained.

You can determine the height of the step by the formula below: 2.05 / 19. The number after the calculation is 0.11 m. The final number of steps will be 28 pieces: 3 / 0.11. The result is a figure equal to 27.3. It should be rounded.

You can take the following key parameters for the stairs. The lifting height is equivalent to 300 cm, the diameter is 220 cm, the inner diameter is 20 cm, the total angle of rotation is 510 degrees, the thickness of each step is 5 cm, the height of the step is 11.1 centimeters. As for the angle of the step, this figure is 18.9 degrees, the length of the step is 100 centimeters.

Installation

If you will make a spiral staircase to the second floor with your own hands, it is important to familiarize yourself with the technology of the process. Initially installed and fixed rack, which is located in the middle. In the next step, you can begin to install the steps and spacers. The master needs to fix the upper part of the structure, and then strengthen the railing and handrails. If you are going to make a staircase that has cantilevered pinching of steps, then beech can be used as material. All blanks can be cut using a lathe designed for woodworking. A hand-held electric tool will also come in handy. If you do not have such equipment in the arsenal, then you can order the preparation of parts from the master. A plumb line allows you to transfer the point of the angle of the opening to the floor surface. This will be the starting mark for determining the position of the support. On the base of the floor, it is necessary to draw a line that is parallel to the opening cut out in the ceiling.

Recommendations for work

When a spiral staircase is made of wood with your own hands, you have to prepare the drawings yourself or order from a professional. At the next stage, a cylindrical element and a starting stage should be put on the steel core. By the same principle, the remaining elements are installed. After you managed to assemble the central rack and steps, you should fix the upper platform. Further racks for a handrail are established. The steel core bolt passes through two steps and ends slightly above the uppermost step.

Final work

You can make a spiral staircase with your own hands from metal, but for this you need to have the skills to work with a welding machine. If you decide to use wood, then at the last stage you can stain. To begin with, the surface of the stairs is cleaned with sandpaper, then it is cleaned of dust and covered with stain.

Features of the manufacture of metal stairs

Do-it-yourself spiral staircases can be made of metal, drawings of such structures can be made by professionals. Assembly of the system must begin with the installation of the central rack. After that, bushings are put on, and after that - washers and steps themselves. After this part of the work is completed, the steps should be deployed around the rack to the required distance. Now comes the turn of mounting brackets. The upper stage is fixed on the floor. When making a metal spiral staircase with your own hands, the drawings will allow you to adhere to the technology. At the last stage, the railing as well as the handrails are mounted.