A gable roof system is considered a fairly inexpensive option for roofing. It is often chosen by owners of private residential buildings. This is a simple and practical rafter system. Its design is reliable and provides the necessary protection from the weather. Next, we consider in more detail the possible options for its device.

General information

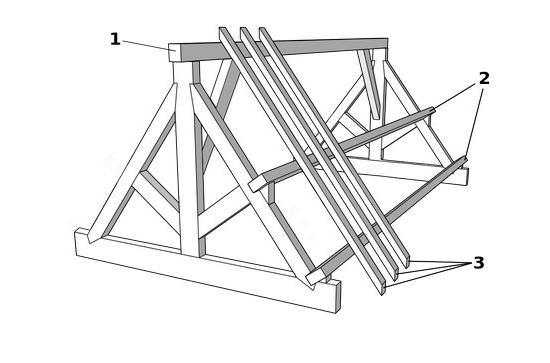

Gable rafter system is a connection of rectangular planes at an angle. At the same time, triangular-shaped openings remain on the sides. Gables are inserted into them. The roof structure (rafter system) includes various supporting and retaining elements. They provide reliability and durability. Next, we will consider what the roof structure (rafter system) consists of.

Mauerlat

The element is represented by a square-section bar. It is made from coniferous species. Mauerlat is designed to evenly transfer the load from the rafter legs to the supporting walls. The size of the beam, as a rule, is 10-15 cm. It is laid along the load-bearing walls. As a fastening element, rods on the thread or anchors act.

"Leg"

It is a beam, the size of which in the context of 15 X 5 (or 10) cm. Using this element, the triangular outline of the roof is assembled. He, in turn, bears all the burden of atmospheric phenomena: snow, hail, rain or wind. To ensure greater reliability, the rafters are located at a distance of 0.6-1.2 meters. The distance is the shorter the weight is supposed to carry out the roof. In addition, in some cases, the structural features of the roof covering will also affect the step size .

Sill

This beam has the same section as for the Mauerlat: 10 x 10 cm. It is laid horizontally on the supporting walls. This provides an even load on the racks.

Tightening and struts

The first element completes the "legs" triangle. Tightening prevents it from spreading. The struts fulfill the task of the transmission link between the rafter legs and the supporting elements. When connecting these parts with a puff, a truss is obtained. This item is very sturdy. Even in the case of the formation of a large span, the farm will be able to withstand all the loads.

Racks

For these elements, the same beam is used as for tightening. Racks are arranged vertically. They take the load from the ridge and transfer it to the supporting inner wall.

Crate

Frame elements are laid perpendicular to the rafter legs. As parts of the lathing, boards or bars can act. This design transfers the severity of the roof to the legs of the rafters and provides their additional fastening. For the device of the lathing, it is better to take trimmed elements. However, if this is not possible, you can use an unedged board or timber with the bark removed. If a soft roof covering is used, for example, shingles based on bitumen, then the crate is solid. In this case, plywood sheets (moisture resistant) act as its elements.

Skate and overhang

The first element is the top of the roof. Here the roof slopes are connected. The skate is formed by joining the legs. It is located horizontally. An overhang protrudes at a distance of approximately 40 cm from the walls. This element protects against rainfall.

"Mares"

These elements form an overhang. "Mares" are necessary only when the rafters are too short. For these elements, boards of a smaller section are used.

The rafter system of the house: types

There are only two of them: layered and hanging type. The latter apply when the walls of the external walls of the building are located at a distance of ten meters from each other. Another condition under which a hanging roof truss system is used (a diagram of it is shown in the article) is the absence of a load-bearing partition between opposite elements of the building. If it is, then the layered type is used. If the separation inside the structure is carried out using columns, and not a load-bearing wall, both rafter systems are used. The drawing will consist of elements located at an angle, and hanging parts between them. Next, we consider the structures in more detail.

Hanging type

A feature of this system device layout is the location of the rafters with support on the side walls. The minus in this case is the formation of a bursting load, due to which the walls can undergo destruction over time. To prevent this phenomenon, a puff is used to connect the rafter legs. As a result, a rigid triangle is formed that does not undergo deformation under load. Instead of puffs, floor beams are often used . They are especially relevant if it is planned to equip the attic space. Such a rafter system with a do-it-yourself gable roof is equipped quite simply. The advantage of this structure is the lack of need for fixing the Mauerlat. At the same time, those structural elements where the rafters rest on the walls are quite simply attached. A board laid through an insulation layer will make the farm even and stable. This is made possible by providing a larger footprint. There are several types of hanging rafters. They are all three-jointed.

Simple triangular structure

This rafter system with a do-it-yourself gable roof is the easiest to assemble. The structure is a closed triangle. Its two upper sides are subject to bending stress. The tightening used in this design does not work exclusively in tension and does not apply to the supporting element. In this regard, it can be replaced with a steel cord. There are several options for organizing the device cornice unit. For this, plate or board mounts can be used, as well as frontal orthogonal cuttings.

Tri-hinged triangular arch using raised puff

Such a rafter system of a gable roof with their own hands is equipped in the event that it is supposed to equip the attic room. In this case, the puff is installed not at the bottom, but at the top. In this case, the tensile load increases. The rafters themselves are held on the Mauerlat beams. In this case, the load becomes uniform, because of which the whole rafter system of the gable roof will be more stable. The calculation of the structure should be carried out taking into account the fact that the edges of the elements should protrude beyond the external walls of the building. To prevent sagging, tighten the suspension. This is especially important when it is planned to construct a false ceiling or lay an insulating layer. If the puff is short, it is fixed to the ridge and crossbar. For this, two boards are nailed. If the puff is long, then several pendants are made.

Open type

If such a rafter system of a gable roof is arranged with your own hands, then it is necessary to place a vertical beam exactly in the middle. The weight of the roof will pass through it from the ridge to the internal load-bearing wall located at the same distance from the edges of the building.

Indisputable layered structure

Do-it-yourself rafter system of a gable roof can be mounted in three ways. The first option provides for a Mauerlat as a support. Or rafters are hemmed with a special beam. As a mount, a notch is used with a tooth. To ensure reliability, the structure is insured with a wire or clamps. In the upper part of the elements, holes are mandatory fixed. According to the second option, the roof rafter system is equipped with its own hands using a movable joint like a slider. You can also mount using a piece of bar. In order to ensure strong leg retention, a nail is driven in from above or a flexible steel plate is fixed. The rafters lying on the ridge run above are attached in pairs to holes or to the run. As for the last installation option, there is a rigid connection. Parallel to the ridge element, bars or planks are packed on both sides. In this case, a strong bending load is exerted on the beam. However, the rafters bend much less. This installation option is somewhat more difficult to perform than the first. In this regard, it is used less frequently.

Spacer elements

Such a roof device is almost similar to the above options. However, there is a nuance: the movable fastening of the legs must be replaced by a fixed (rigid) one. In this case, the bursting load of the rafters will be transferred to the bearing walls. In general, such spacer elements act as an intermediate link from an inclined to a hanging system. However, here you can do without a run. To equip the spacer system, a very strong fixation of the Mauerlat to the wall of the house is required. At the same time, the building elements themselves must be strong and thick.

Rafters with struts

In this case, additional elements are installed at an angle of 45 degrees. The strut, in fact, acts as the third leg of the rafters, working on compression. Thus, it becomes possible to overlap spans, the length of which is up to 14 m. In this case, beams with a small cross section can be used. There is no need to calculate the brace attachment, since it is enough to substitute it under the rafter and nail from the sides. In this case, the element will not move. However, the main thing is to accurately cut the angle of the strut. In this case, the inclination of the rafter leg should be taken into account. To determine the cross-section of the beam, you need to determine the compression load.

Truss constructions

They are used in buildings with two load-bearing walls. Sub-roof structures include beams laid along the long side of the roof. Under them are installed racks on which the beams are laid. The internal walls of the building and the bed also serve as a support. The rafters in the upper parts are connected one to the other. They are tied with wooden or steel plates. There is no ridge run, and therefore a spacer appears. The puff is placed below the through runs. Thus, the disposition is eliminated. For stability of struts in the lower part fights are fastened. They take compression loads, acting as a crossbar. The fastenings are carried out crosswise.