Epoxy resin is a universal material that is used for the manufacture of interesting crafts, repair of premises, shipbuilding. Usually the substance is sold complete with a special hardener. The volume of the bubble is small, so home craftsmen invent special do-it-yourself fillers for epoxy. They allow you to change the appearance of the finished product, make it unlike others.

What is epoxy for?

A synthetic oligomer was invented back in the 20th century, but craftsmen still come up with new areas of application. It is perfect for performing beautiful crafts, as well as for filling various surfaces. The material is never used in pure form. For polymerization, the main component must be mixed with a hardener.

Epoxy filler - what is it?

This is a special additive that allows you to increase the volume of the substance, change its appearance and structure. This group also includes dyes of natural and synthetic origin. In construction stores, finished compounds are sold. However, you can make any epoxy fillers with your own hands.

Varieties

The most common application of this material is filling various voids, covering slots and joints. Epoxy adhesive is not suitable for this purpose, so the resin mixed with the filler will be an ideal solution. The substance to be filled should be selected carefully. It should be homogeneous and not burden the composition. There are several types of epoxy fillers. Conventionally, they are divided into natural and artificial (synthetic). All of them have advantages and disadvantages.

Aerosil

Additive is needed to prevent smudges. It is necessary when using the material on vertical surfaces. The mixture has a creamy consistency, after hardening it acquires an increased density, therefore Aerosil is used as a filler for epoxy resin for strength. The supplement is well combined with other components.

Microsphere

The substance is the smallest balls that are filled with gas. They look like fine-grained powder. Microsphere filler for epoxy resin features low density and light weight. When mixed with resin, the viscosity necessary to process inclined planes, corner joints and seams appears. A large amount of a strong mixture with a foamy structure is obtained. It lends itself perfectly to grinding after hardening. The disadvantages of the component include a decrease in the strength of the adhesive joint.

Graphite powder

It can be used both for coloring the substance and for creating a perfectly even and smooth structure on the surface. Black fine-grained powder is used in the automotive industry and is added to the special coating used to process the bottom of the machine. This allows you to increase the impact resistance of parts. Cons of the coating is an increase in the fragility of the material when exposed to sunlight and an increase in electrical conductivity in salt water.

Talc

A simple baby powder, bought at an industrial goods store or pharmacy, copes with the function of a filler for epoxy. According to its properties, talc is similar to aerosil, but has a finer fine structure. Thanks to this, you can get a flat and fairly durable surface. The downside of the supplement is that it is capable of absorbing moisture. This leads to deformation of the surface if water gets on it.

Aluminum powder

It helps to give the composition a nice silver-gray color, so this component is often used as a decorative finish. If you add a little more substance, making the texture thicker, the strength of the material after solidification will increase significantly.

Titanium dioxide

This component, like aluminum powder, can serve not only as an additive to increase volume, but also as a substance for pigmentation. When mixed, a white epoxy filler is obtained. If the surface on which you plan to apply the composition will be exposed to direct sunlight, it should be additionally treated.

Natural supplements

The difference between natural fillers for epoxy is that they are of natural origin. The most common components for mixing are:

- Wood flour. It is used to increase the density of the putty, to give the composition a natural structure and color similar to wood. The disadvantage of the mixture is the loss of uniformity. It is much more difficult to work with such material, it is more difficult to lie on a flat surface.

- Fiber. This component is both natural and artificial. Commonly used are cotton, linen, glass, cellulose fiber. It is first finely ground by grinding. The substance significantly improves the bonding and bonding properties. The additive copes well with impregnation, filling gaps.

- Fine sawdust or dry foliage. This accessible material can be found anywhere. However, it must be borne in mind that before mixing with epoxy, the material should be crushed, otherwise the filling structure will turn out to be rough.

DIY fillers

To prepare the putty, it is not necessary to purchase special additives. You can always make a filler for epoxy with your own hands from improvised materials. Many masters using home experiments have achieved interesting results using:

- Cement. It copes well with the duties of the supplement. After the epoxy has completely hardened, the surface will become very strong, although it is necessary to strictly observe the proportions and add dry matter not more than 2 parts per 1 part of epoxy, otherwise the coating will turn out to be very brittle and may crack.

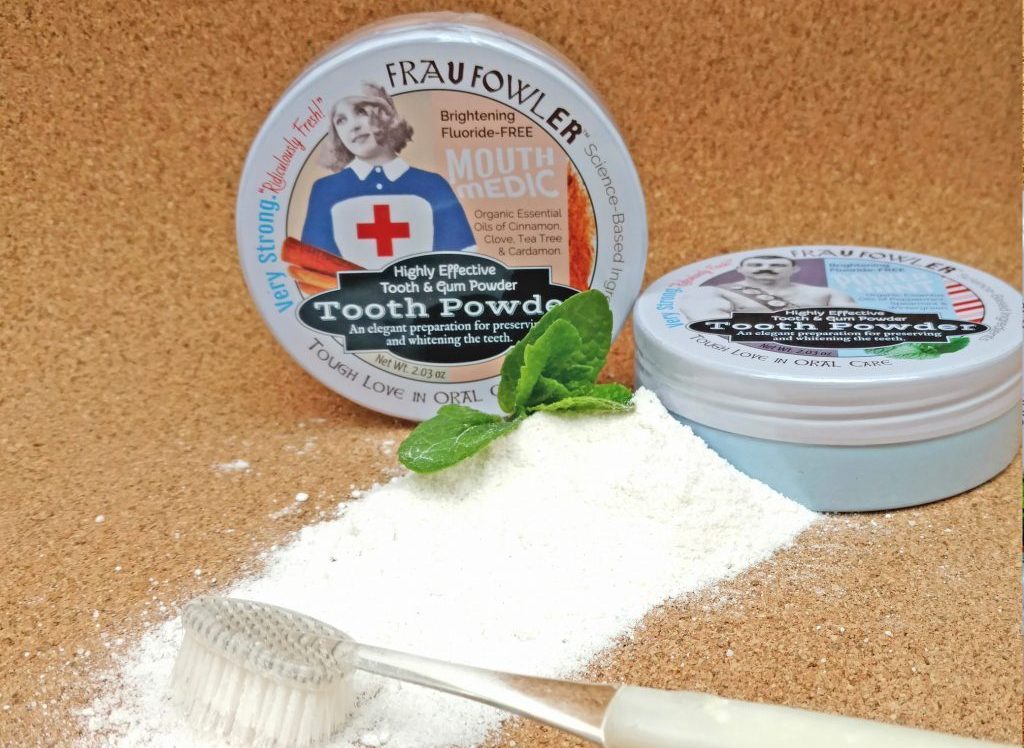

- Dentifrice. Like chalk, this additive is too hygroscopic. Due to the ability to absorb moisture, the composition cannot last for a long time, so you can use this filler only in places where there is not too much humidity.

- Alabaster or gypsum. These substances make the composition much stronger. After adding, the ductility of the resin is reduced, and you can spread it on any surface. Due to the heavy weighting, it is difficult to work with such a material on a horizontal surface, which is directed downward.

- Flour In an extreme case, when there are no other additives, you can use the simplest flour that can be found in any kitchen. The material lends itself well to processing after hardening. However, then the hardening time of the epoxy is increased several times.

- Sand. This epoxy filler will not work for relief. It is used extremely rarely. Before starting work, you need to carefully sift the sand through a fine sieve. After the composition has hardened, the surface will have a slightly rough structure. You can use this putty for decorating in the open air. It withstands sunlight and is not exposed to moisture.

- Fiberglass. It is used on surfaces where it is necessary to improve insulating properties. When working with this material, you must follow the safety rules by putting on a face respirator and gloves on your hands.

When you need to achieve a decorative effect and paint the epoxy in a specific color, you can use different dyes:

- ink from ballpoint or gel pens;

- aniline dyes;

- colors for nitro paints;

- dried and crushed gouache paints;

- dyes for easter eggs.

Often glitter made from confetti or Christmas tree tinsel is added to epoxy products. Thanks to this, the craft becomes even more elegant and beautiful.