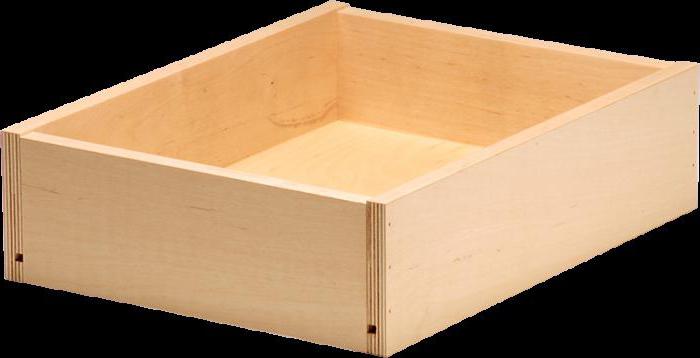

Do-it-yourself plywood box is easy enough to make if you have the necessary tool. This craft can be very useful at home for different fields of activity. The production procedure is very simple, and the main design features will be presented below. Work brings not only benefits, but also relaxation, distraction from daily activities.

Multifunctionality of plywood box

A variety of products are sold in construction stores, they can be used to store vegetables, transport tools and other things. Of course, you can buy them, but it is much more pleasant to do the work yourself. The main thing is to initially determine the type and design of such a tank.

Plywood is often used as a material, since it is aesthetic, strong and easy to process. A plywood structure will be able to withstand the largest loads, and if you really need to carry or store heavy things, you can use a sheet of plywood, which will have a large thickness. Products from such raw materials can be used in various fields.

Tools and materials required

If all the tools and materials are prepared, even an inexperienced person will be able to make a box of plywood with his own hands. To get started, you need to prepare the following tools:

- Drill.

- Screwdriver.

- Jigsaw.

- Furniture stapler.

- Roulette.

Having prepared the tools, you still need to stock up on materials. A plywood sheet can be of different thicknesses, it all depends on the purpose of use of the product. It should be noted that the bottom should be thicker than the walls and cover. Materials for the manufacture include:

- Plywood that will serve as the bottom and walls.

- Wooden blocks (as a decor).

- Nails

- Wood glue.

- Wheels if the box will move.

- Lacquer.

- Putty.

In addition to material and tools, you will need to prepare a drawing of a box of plywood as a whole and a diagram of each part separately. If you observe the dimensions according to the drawings, then the design will turn out to be of the correct form and suitable for any need.

Types of products

Today the plywood box can be made of different shapes, types and for different purposes.

The main types include:

- Mailbox.

- Product for the collection of children's toys.

- Design for sending fragile and valuable parcels.

- Toolbox.

- For storage and transportation of vegetables, fruits and other products.

In addition to the main types, you can make gift wrappers from raw materials, as well as niches as a cabinet and other things.

Thickness required

The thickness of the material should be selected depending on the objectives pursued. For example, for storing children's toys, it will be enough to use a material thickness of 4 to 6 mm. Similar parameters are suitable for storing food. If the product will be outdoors, then the thickness should be from 8 mm. For heavy things or for tools, it is also better to use thick material.

Plywood is an ideal solution for storing and transporting various things. Such products retain their naturalness, and are not inferior to massive boards. Plywood is a safe material for the human body, unlike plastic, from which many products are made that are sold in stores.

Step-by-step instructions for manufacturing a regular box

Before you make a box of plywood, you should determine the requirements for it and the further purpose of use. For this:

- A drawing is drawn on the sheet.

- Measurements and calculations are being carried out.

- All sizes are transferred to the prepared tree.

- A pattern is made on the surface of the material.

- Parts of the structure are cut with a jigsaw.

- The edges of the parts need to be smoothed out with sandpaper or a file.

- If the joints are grooved, then lines are drawn on the inner walls of the parts.

- Next, the box is assembled in a single design. To ensure reliability, all elements are glued with glue, and then knock down with nails or fastened with self-tapping screws.

- Handles are used for carrying, which need to be fixed, or openings for the hands are cut.

- Inside, you can install partitions by dividing the area into cells.

If you have experience working with wood and tools, then you will be able to complete the work quickly and without much difficulty. If the product involves a lid, then you need to install trims inside the box and cut out the lid from the sheets on which the handle is mounted. Additionally, you can install the loop.

Step-by-step instruction for manufacturing a tool box

Toolbox made of plywood can be made in a variety of shapes. Below is a step-by-step creation of the usual simple box, medium in size and with handles for easy carrying:

- A product drawing is made, and the necessary raw materials are prepared.

- The drawing of all elements is transferred to the plywood sheets with a pencil and a ruler.

- Elements are cut out from the sheets, they should turn out 5 pieces, since the cover is not supposed in this case.

- The corners of the elements are cleaned with sandpaper, and then everything is connected. First, glue for the tree must be applied to the elements and fastened with nails or self-tapping screws.

- Further, handles are attached to the product. They can be made of wooden bars that are simply screwed on both sides.

- If you want to store different little things or individual types of tools, then in the middle, walls are installed that will divide the internal area.

As you can see, making a simple plywood box with your own hands under the tool is quite simple. Of course, if it is structurally more functional, the creation process will be a bit more complicated.

Step-by-step instructions for making a mailbox

From sheets of plywood with a thickness of 4-5 mm, you can make a mail box that will decorate any home. The work is simple, and it will not take so much time. For a detailed review of the manufacture, it is recommended that you read the step-by-step creation instructions, which are presented below. Here in this way you can make a mailbox from plywood with your own hands:

- The basis of the product is made of wooden blocks. The length of the slats should be 30 cm, and in width one rail should be 2 cm each. Plywood in this case will be used for lining. Moisture resistant material is recommended. For the product, two sheets of each type will be required: 30 x 25 cm for the front and rear parts, 30 x 6 cm for the side and 25 x 6 cm for the upper and lower.

- Having cut out all the parts, the wood must be treated with protective agents that protect the material from moisture and insects.

- Next, 4 bars that play the role of a frame are connected with self-tapping screws.

- Now in the sheet of plywood that will be used for the top, a long hole is cut for letters and newspapers.

- The side walls, bottom and top, as well as the rear, are screwed to the frame. The front wall will serve as a door with a lock for picking up correspondence. Therefore, small loops are attached to the frame. Next, the front part of the plywood is put on the hinges, and one lock loop is also installed on it. The second loop is mounted on the side of the plywood. Thus, it will be possible to install a padlock.

- In the upper part, to protect mail, a small metal visor should be installed. This will not allow sediment to enter the box.

On this, the process of creating a container for letters and newspapers is completed, and it can be installed on a fence or in another place.

Finishing work

Ready-made plywood box should lend itself to finishing. You can cover it with varnish, and if there are cracks, then they are pre-sealed with putty. As a decor, you can glue the lining on the product. They can be cut with a jigsaw from plywood sheets, so that the overall appearance will not be lost.

For better preservation of the material, it is necessary to process the inner walls with varnish. If the box will be part of the decor in the room, then the outer sides can be painted in a certain color using ordinary paint. If putty is used, then before applying varnish or paint, the surface should be sanded with sandpaper, and the product itself should be smooth to the touch, without roughness.

Conclusion

It’s easy to make a functional box of wood yourself, and if you have a good tool and at least basic skills in working with wood, you can make good money on creating different products from plywood. All wooden structures that are made by yourself are much more expensive than machine production. They are in demand by many people, as they are exclusive and are performed in a single copy. Therefore, a usual hobby and hobby can grow into a small business.