In the current information and automobile age, everyone knows that the ergonomics of a machine are largely determined by shock absorbers. This is an indispensable part of the suspension of a modern car. How do various shock absorber manufacturers compete in the car market? Reviews of motorists to some extent reflect this phenomenon. After all, the picture of this competition for the consumer is very curious: American, German, Japanese companies set the tone for it. As a result, single-tube shock absorbers dominate double-tube ones.

Briefly about the modern shock absorber market

The annual Russian Automotive Component of the Year Award allows you to identify the most successful brands in each category. So, in 2016, DEMPHY became the leading brand among Russian shock absorbers, having introduced budget-class struts and shock absorbers of the Comfort series of improved premium and drive quality. The company's products - front and rear shock absorbers VAZ, IL, Lada, Ford Focus2, Renault Logan. Today DEMFI is a small enterprise (less than 60 people work on it), but it is high-tech and high-tech, capable of expanding production subject to proper demand.

UAZ Hunter shock absorbers from the Petersburg enterprise Plaza also deserve high marks. They are possible in three versions: “standard”, “sport” and “extreme”. Among foreign ones, Monroe (USA / Belgium), TRW (Germany), KYB (Japan) and EGT (Lithuania) respectively won the first and fourth places.

How to figure out a beginner-amateur, which shock absorbers are better? After all, the world's leading manufacturers demonstrate more and more sophisticated developments of international class. For example, only Monroe today enters the market with various shock absorber brands “reflex”, “sensa-track”, “original”, “adventure”, “van magnum”. It is they who currently dominate the modern car market. A sign of the high reputation of the Monroe company is a complete set of its shock absorbers, recreated directly on the assembly line of Ford, Nissan, Renault, Mitsubishi, Volvo, Porsche.

The German auto industry uses mainly domestic shock absorbers. Reviews of motorists indicate that Opel, Mersedes, Audi traditionally use the products of the ZF concern (which owns the brands Sachs, Boge, TRW). The original shock absorber Toyota, Mitsubishi is the products of the Japanese company KYB (brand KAYABA). However, this brand is becoming increasingly popular in both the New and the Old World. Currently, the following A series are imported: Premium Oils, Excel-G Oils, Gas-A-Just Gases, Ultra-SR Sports, AGX Adjustable, Monomax Off-Road.

What shock absorbers does Hyundai (Korean company) put on its conveyors on its cars? It is logical that from another Korean company that produces auto components. Moreover (this is a feature of Korea) relatives manage both firms. The manufacturer of shock absorbers under the brand MANDO is called the Halla Group company. Its plants operate in Korea, India, Turkey, China, Poland, and the USA. Tens of millions of dampers are manufactured per year. They install MANDO shock absorbers Ford, Peugeot, Nissan, BMW, Suzuki, Renault, GAZ on their conveyors. It is significant that the shock absorbers of KIA (another Korean auto corporation) are also supplied from the Halla Group.

Brand competition

The competition between manufacturers is so significant that imported brands successfully oppose the local ones. In particular, some drivers prefer Japanese cars to European ones. So, according to reviews of vehicle owners, the Renault gas-oil shock absorber manufactured by Kayaba is currently in high demand.

It is preferable for most of the current models of this brand: Kengo, Megan, Traffic, Premium, Master, Klio, Laguna, Magnum, etc. Its price is 30% higher than the cost of the oil device, but it is noticeably more effective when driving on rough roads. Therefore, the Renault gas-oil shock absorber drivers prefer oil, cheaper.

Note that the Renault models, designed for extreme driving on solid roads, are equipped with special shock absorbers - Kayaba Ultra SR. After all, speeding overcoming corners determines a large load on such products, both compression and rebound. However, for everyday city traffic they are not optimal, since they have increased rigidity, and for imperfect roads, as you know, softer springs are needed.

However, in this article we will not limit ourselves to a review of the shock absorber market. Our goal is wider - to reveal the secrets of their successful operation. As you know, shock absorbers are the supporting elements of the suspension, respectively, imagine an ideal suspension. As you know, this element performs two tasks:

- Firstly, it connects automobile wheels with a body. Thanks to it, the necessary traction of wheels with the road is provided.

- Secondly, it neutralizes (amortizes) the vibrations that occur during movement.

Depreciation is ...

A closer look at the suspension elements makes it clear that shock absorbers are damping (damping vibrations) devices. At the dawn of the automotive industry (XIX - beginning of XX century), these parts did not exist at all. At low speeds of the first cars, only springs were enough for the suspension balance. However, in the modern dynamic age of speeds in the suspension there are not only improved springs (springs), which today are often called a somewhat abstract - elastic element. This is not enough. To illustrate the above, let us consider a typical case of a car overcoming a bump in a road.

At the same time, the task of the elastic element is obvious - when the wheels hit the roughness of the road, it should soften this blow. However, a modern car, when driving, has tremendous kinetic energy, with which the "elastic element" does not cope with the "freelance emissions" on the bumps of the road at all instantly. Therefore, the inertia of the body causes the springs to oscillate after a collision. This is an extremely undesirable effect. After all, it can lead to a resonance that can lead to a car accident (remember physics and force vectors). This happens when the spring’s swing from another roughness of the road develops with its previous swing, which, alas, has not been extinguished. Auto engineers responded properly to this phenomenon by inventing a special damping device.

At the beginning of the 20th century, a damper (shock absorber) was created to damp vibrations of the elastic element. The idea of his work was quite simple and elegant. After the roughness of the road causes the spring to compress, its subsequent expansion and, accordingly, the oscillation will extinguish a special device - a shock absorber. However, we will not consider it as the only part that protects against vibration, because for the perfect behavior of the car on the road, there is not only a shock absorber and an elastic element.

Not single shock absorbers

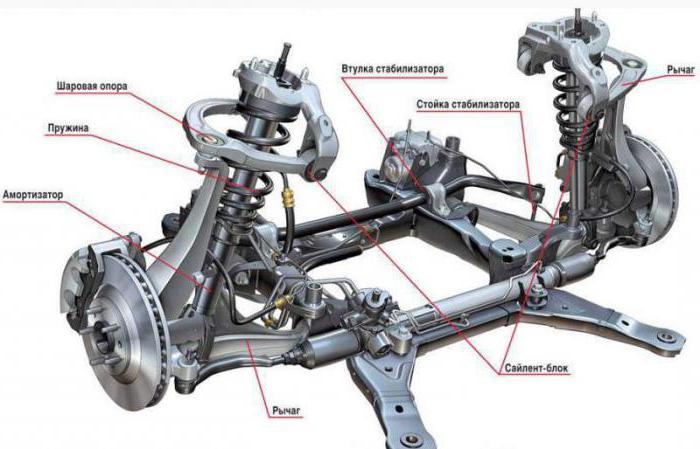

The shock absorbers mentioned above are special elements for maintaining the maximum possible horizontal and stable position of the suspension in space. But for a truly workable suspension, this is not enough. For maximum comfort of passengers and the driver, so that the car does not count bumps, but soars smoothly along the highway, the coordinated work of shock absorbers and other devices, such as:

- tires made of excellent rubber, providing proper traction;

- unworn springs and suspension springs (except for the functions already mentioned by us) must maintain the clearance indicated in the technical specifications and keep the machine at the same level;

- additional rubber-metal elements (hinges and compression buffers), damping vibrations from touching metal parts to each other;

- guiding devices that determine the desired angle of rotation of the wheels.

However, be that as it may, the shock absorbers are the main damping device of the car - the subject of this article. With their help, the harmony of constant contact of the wheels with the roadway is achieved (the car goes as if attached to a road), and, in principle, truly comfortable driving becomes possible.

What is the shock absorber in appearance?

Outwardly, it looks like a cylindrical device attached on one side to a car frame, and on the other to a suspension. A piston moves inside the shock absorber. This is a rod moving in a cavity filled with gas, oil or brake fluid. Due to the compression of the oil by the piston, its speed decreases. Suspension oscillations determine the vibration of the shock absorber piston. The more actively the suspension moves (which happens on rough roads), the greater the resistance shown by the shock absorber. Various blows received when driving a car on rough roads, as well as vibrations during sharp braking or at the beginning of movement, are damped (softened) by a shock absorber. In this case, the kinetic energy of the oscillation passes into the thermal energy obtained when the piston compresses the oil. The resulting heat is dissipated.

Depreciation process

How does the shock absorber react when a wheel collides with a road pothole? It contracts, absorbing the blow, while its piston works in concert with the suspension springs. However, the cycle of the device’s operation does not end there, since it expands, that is, the piston extends from the shock absorber. If it weren’t for him, the suspension springs would have thrown the car body up with the same force with which they were compressed in a collision with a pothole. However, the movement of the piston of the shock absorber of the expansion vehicle is also inhibited by oil.

Shock absorber design

Technically, the device during its operation converts the mechanical vibrations of an elastic element into thermal. Replacing shock absorbers that have exhausted their effective use is a responsible matter. After all, the one who installed the "new thing" immediately notices changes in the behavior of the car. Therefore, for a knowledgeable driver, the correct selection of shock absorbers is critical. And believe me, there is plenty to choose from. The car market is full of relevant products of manufacturers of eminent (branded) and not very. We will return to the coverage of this aspect. But first, it will be logical to distract from the principle of “whose will you be” and try to “see the root”, that is, to understand the fundamental differences between different types of shock absorbers (A).

Judging by the design differences, then A is divided into single and double pipe. If we classify by the type of working substance that dissipates heat obtained after the conversion of kinematic energy, then the shock absorbers are oil, gas-oil and gas.

Double pipe products

What shock absorbers can be recommended for a quiet, so-called family driving? Relatively inexpensive, simple in design, which do not withstand extreme. Two-pipe A are more inert and have a large mass. In addition, the double casing cools worse. In this case, the damping efficiency of two-pipe devices depends on the correct installation. As you know, the shock absorber is fixed 100%, fixed strictly perpendicular to the suspension, but if this angle increases to 50 °, then its effectiveness decreases to 68%.

The design of such elements includes a working flask, inside of which a piston is located, as well as an external housing designed to store excess oil. During its working cycle, the piston passes part of the oil through its channels, and also squeezes it through the compression valve located at the bottom of the flask. When buying products, special attention should be paid to oil, which should not boil at temperatures below 150 ° C. At the same time, despite the favorable price, they should not be installed on cars of the latest generation.

Single tube shock absorbers

This design is the basis for modern A. Such a shock absorber consists of a single bulb, simultaneously fulfilling the role of both the working capacity for the piston and the housing. It can be hydraulic (oil) or hydropneumatic (gas-oil). The latest modification is also called combined. The principle of operation of oil A is quite simple. There is a working cylinder filled with oil (hydraulic fluid). It moves a piston with special calibrated valves, more precisely with their system, which has characteristics that are specially selected for the suspension of a particular car model.

The dynamics of such a shock absorber is as follows:

- With the valves closed, the hydraulic fluid passes only through the bypass channel of the piston. The hydraulic characteristic of the shock absorber becomes stiff.

- If the valves adjacent to the compensation chamber A are opened, then its hydraulic characteristic becomes softer.

Moreover, in order for the shock absorber to work, the compression-functioning valve must allow more hydraulic fluid to pass through than the non-return valve. Thus, with open piston valves, the stiffness of the shock absorbers decreases.

Combined shock absorbers

In hydro-pneumatic (gas-oil) shock absorbers, instead of air, compressed gas is used under a pressure of 4-20 atmospheres. Its motorists call in their own way - "gas backwater". Moreover, gas pressure is not a whim, but a way to reduce aeration (mixing air with oil), as well as an additional element of suspension elasticity. Monotube A does not have a lower compression valve. The piston fully controls the resistance both during compression and during rebound. It is possible to place more oil in them than in two-pipe of the same volume, which means that better damping is achievable with their help.

Guided and magnetic shock absorbers

Leading manufacturers of shock absorbers are quite original in their attempts to solve the technical problem of the adjustability of such devices. The American-Belgian company MONROE made special adjusting grooves on the walls of the single-cylinder A working cylinder, which are used to adjust for a quiet or active ride. The Japanese company KYA installed a separate control valve in the bypass of the piston in the lower part of the single-tube tank with remote tank A. The German concern ZF created its Opel-Astra controlled shock absorber using a two-pipe gas-oil construction. Two electromagnetic valves in the lower part of the shock absorber and in the piston are regulated by a special processor that monitors the parameters of the wheels, steering wheel, and suspension.

Even more promising is the new, so-called Chevrolet magnetic shock absorber installed last year on the Chevrolet Corvette. This is a joint promising development of the automaker and Delphi Corporation. The magnetorheological liquid used in them instead of oil is capable of changing its viscosity with a high frequency (up to 1000 times per second) under the influence of an electromagnetic field. In this case, the valve system is not fundamentally used: damping is carried out exclusively due to the magnetorheological effect. Such a design is very promising: there is no need for lateral stabilizers, the device of A itself is simplified, and there are impressive possibilities for monitoring and controlling the stiffness of the suspension.

Correspondence of the hydraulic characteristics of the shock absorber to the road relief

The shock absorber design must take into account various aspects of its operation. After all, poor-quality road surface determines various modes of its operation. On the one hand, repeated small irregularities do not allow A to straighten up. In this case, a soft hydraulic characteristic is relevant. Large potholes threaten its full forced compression, which often causes damage to the shock absorber. At the same time, a rigid hydraulic characteristic of the device is in demand.

Therefore, it makes no sense to ask: “Which shock absorbers are better - soft or hard?” Indeed, not only their softness, but also their controllability becomes relevant in terms of long-term operation.

Another characteristic - the heat dissipation of the shock absorber - is important for its correct operation. Indeed, in the conditions of a hard regime of heat more is released, and it should be taken away. On the other hand, in winter the oil in the shock absorber thickens, and its hydraulic characteristic becomes more rigid. At the same time, the right choice of oil becomes important for the motorist. It is undesirable to use liquids with a high content of additives, because the latter have the property of softening the rubber. Most often, experts recommend the use of branded oils GRZH-12, AFT. However, in frosts, you should choose a liquid with a viscosity of 75Wt. For oils containing silicone, the degree of viscosity is determined in other units — cPs, which are about 10 times greater than Wt.

Diagnostics of shock absorbers

Since there is nothing eternal, shock absorbers are also subject to wear. The driver should be diagnosed with this phenomenon on time. As you know, the replacement of shock absorbers that have lost their functionality should be done immediately upon identification. And the most effective is the comprehensive replacement of A: in pairs on each axis - both on the front and rear. After all, it is naive to expect perfect damping after incomplete replacement of shock absorbers.

However, this alone is also not enough. It is necessary to diagnose the whole complex of car devices involved in damping. Indeed, the normal operation of shock absorbers is possible with good rubber-metal elements (hinges and compression buffers), unworn springs and springs. Maintenance of all the above parts and mechanisms will reduce the load on the shock absorbers.

When to replace

For the driver, there are first signs indicating shock absorber wear. Let's call them:

- increased braking distance due to poor handling;

- decrease in comfortable speed for entering the turn;

- decrease in safe aquaplaning speed (traction if there is water on top of the ice);

- worn-out A begin to make sounds when the car enters into a turn or overcome bumps.

When shock absorbers break

Modern car corporations are making more and more efficient A, bringing maximum comfort to the trip. However, if they serve laid 80 or more thousand kilometers of track on concrete tracks, then poor-quality road surface with potholes leads to unpredictable breakdown of the mentioned devices much earlier.

Damage occurs most often inside the shock absorber when the car’s wheel hits a pothole. Oil begins to leak out of them. The rod is deformed from impacts, and the valve in the working chamber is knocked out in soft shock absorbers. Such breakdowns mean A failure and require unconditional replacement. Therefore, motorists weigh the pros and cons, buying shock absorbers. At the same time, feedback from drivers posted on special forums should also be taken into account.

It can also spoil the dust and dirt that has got into them. Small particles, once in the working chamber, leave scratches on the stock. As a result, the oil seal ceases to be airtight, and as a result, an oil leak occurs. Even more perfect single-tube is A with a remote compensation chamber. The improved design allows the use of more compressed gas and oil. With an even more advanced improvement, a system of valves regulating the stiffness of the shock absorber is installed in the path of the oil flowing from the main cylinder to the external chamber. There are modifications A, where tubes for oil flow pass over the outer surface.

Conclusion

Today's motorists are quite easy to choose the right shock absorbers for their car. At the same time, you can use the services of both a specialized traditional and an online store. For the convenience of customers, the choice of shock absorbers they need begins on the online store website with an indication of the car model. After this simple manipulation, the buyer sees which brands and brands shock absorbers are suitable for him. If he further doubts the choice between alternative brands, then numerous motorists reviews on specialized forums and various ratings will help him form an opinion.