A carburetor is one of the most important components in a car. This device is designed to prepare an air-fuel mixture, which will then be fed into the intake manifold of the engine. Carburetion is the process of mixing fuel and air. It is thanks to this process that the engine works. Consider the device of this device, as well as ways to adjust the carburetor.

Types of devices

On older cars, two types of carburetors are used. The first are bubblers, which are very rare. They were replaced by more effective and efficient membrane-needle and float analogues.

Membrane-needle aggregates consist of chambers separated by means of special membranes. Between themselves, these parts are fixed using a rod. One end of this mechanism resembles a needle. During the operation of such a device, the needle moves up and down, opening the fuel supply valve and closing it. This is the easiest type of carburetor. It can be found on lawn mowers, engines of some aircraft, on trucks.

Float-type carburetors are presented in the form of various modifications. However, the principle of action is similar in many respects. The main element of such a device is the camera and the float mechanism. Thanks to the first, fuel and air are timely supplied to the carburetor. Float-type carburetors are a guarantee of uninterrupted engine operation. Bubbling often junk and caused a lot of complaints among car owners. Float - the most advanced mechanisms. With them, the motor has good dynamic and traction characteristics. Adjusting this type of carburetor is quite simple, and even beginners can handle it.

How Solex works

These carburetor models have been used on domestic cars since the 80s. Initially, they were equipped with VAZ-2108 cars. The first units worked with engines of 1.1 and 1.3 liters. They labeled these products as follows - DAAZ 2108. Later, the DAAZ plant began to produce the Solex 21083 model , which was intended for engines with a volume of one and a half liters. Consider the device, because adjusting the carburetor is impossible without this knowledge.

This unit is designed to form a fuel mixture, on which the engine can operate in all modes and at any load.

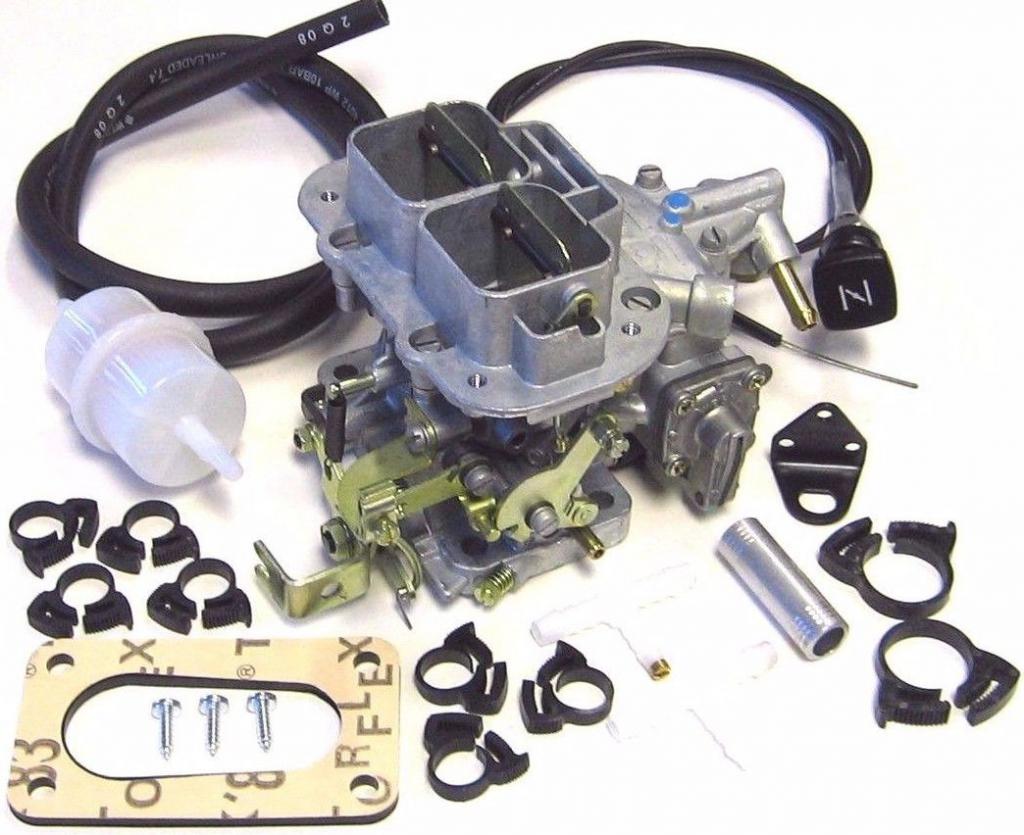

It consists of two parts. The lower part is the main body, which directly houses the diffusers, GDS, a system for ensuring the engine idling, an accelerator pump, as well as an economizer. The device also includes a cover. It has an air damper, floats, a starting device and an electromagnetic valve. Despite the many components, setting up and adjusting the carburetor with your own hands is quite simple.

The carburetor consists of two chambers. The carburetor jets are located in the middle of the chambers, deep in the main body. Above these elements are installed air jets of the main dosing system. The model 21083 also has a fuel mixture heating system. The pipes of the cooling system are connected to it. The carburetor throttles are located at the bottom of the base housing. They open sequentially. The second chamber moves due to mechanical levers.

There are nozzles in the carburetor cover. Through one of them, liquid fuel is supplied to the unit, and through the second, excess fuel goes into the tank. Due to the second pipe, the pressure in the fuel system of the car is reduced.

Major malfunctions

These mechanisms are characterized by certain malfunctions, many of which are solved with the correct adjustment of the DAAZ carburetor. Most often, owners are faced with clogging of the main dosing system. Also, specks can fall into a separately working idle system.

As a result, the nozzle mounted on the solenoid valve is clogged. The diaphragm in the accelerating pump fails, the electromagnetic valve wears out. Often due to excessive efforts when tightening the carburetor, the plane of the lid is deformed. Many problems can be solved by cleaning the carburetor, purging its channels, replacing the repair kit.

Customization

Adjustment of the VAZ carburetor allows for stable engine operation. Engineers have provided several settings. So, the owner can change the fuel level in the float chamber, adjust the engine speed in idle mode, change the qualitative composition and proportions of the fuel mixture in idle mode.

Mix quality setting

In this case, adjusting the Solex carburetor does not cause difficulties even for beginners. Everything is very simple. Before setting something up, you should warm up the engine well. Then, with the help of a plastic screw, the crankshaft speed is set within 900 rpm.

Next, find the screw responsible for the quality of the mixture. It is in the hole on the bottom of the carburetor on the side of the damper drive. In the process of adjusting the carburetor, this screw should be tightened until the speed begins to fall. At the same time, the mixture is leaner - the proportions of fuel are reduced in it. The engine lacks fuel, and he seeks to stall.

Then the screw is unscrewed and a position is found in which the motor starts to work stably. Sometimes it is recommended to dwell on this. But it is better to rotate the screw until the idle speed of the engine stops growing. If the revolutions are too large, they are reduced by the number screw. This is the adjustment of the carburetor with your own hands, or rather, the idle tincture.

To get a good twentieth, it is recommended to configure it with a quality screw. If you twist the quantity screw, the throttle of the first chamber will open more than necessary. As a result, the fuel will enter the diffusers not only through the idle system, but also through the GDS. Due to rarefaction, the motor will suck out gasoline, it will drip from the nozzle of the accelerator pump. The revolutions will float, and the motor will shake.

Idling, jet EMK

Often on this carburetor many owners are faced with problems of idling - it disappears. But also when adjusting the Solex carburetor, the rotation of the quality screw gives nothing. Often this is due to the clogged nozzle responsible for the operation of the XX system. As a result, fuel does not flow through the system, but is sucked out of the GDS. Therefore, there is no reaction to the adjusting screws.

There are several typical faults. This is a blockage of the nozzle and the idle channel, as well as a malfunction with the solenoid valve.

The valve is checked very simply. It is enough to apply +12 V to it and you can hear a characteristic click. If there is sound, then the valve is working. You can unscrew the part - remove the nozzle from it and observe the stock. With a working valve, it will be recessed.

Further, in the process of adjusting the carburetor, it is necessary to blow the idle jet well. This will solve problems with the twentieth, and with the setting. In order for the idle to disappear, one small speck is enough.

Fuel level setting

To ensure uninterrupted operation, it is necessary that there is always fuel in the float chamber. However, the level of gasoline is very important. To configure it you need to remove the top cover. The floats are controlled by folding the tongue, which is located above the needle valve. Much has been written about what level to exhibit, but there is no unequivocal opinion on this subject.

It is best to adjust the VAZ carburetor according to the instructions. This is approximately 25 millimeters from the upper limit of the carburetor to the fuel.

Adjustment Features

The tuning methods discussed above can solve almost all problems with these carburetors. Much depends on how well the carburetor is adjusted. But there are other adjustments. You can also configure the trigger.

Idle jets

On sale you can find jets with a hole from 39 to 42 millimeters. You can choose the right one by rotating the quality screw. If stable maximum revolutions are achieved with the screw almost completely turned off, then the nozzle is set too small.

If the “slide” is found, and the screw is almost tightened, then the nozzle is large. There will not be much difference in engine performance. But in the case of the average nozzle, adjusting the DAAZ carburetor will be much simpler, and the engine idling will be more even.

Finally

Despite the rather complicated device, a carburetor is not as scary as it seems. It is enough to be able to adjust the idle speed, clean the nozzle and know how to rotate the quality screw.