There are various wires and cables, some are laid according to the standard scheme, the second - through the air. It is the first ones that have a special protective layer, which allows to exclude a short circuit. Such a surface is subjected to dismantling in the process of performing the simplest tasks. For example, this is a connection of two cables so that the contact point becomes as dense and works efficiently.

The question arises: "How to remove the insulation from the wires?". To facilitate this process, there are many different tricks and techniques. Because it is not always necessary to completely disassemble the cable, sometimes you just need to strip the contacts and not damage the main core.

In order not to make a mistake and understand exactly how to remove the insulation from the wire, it is worth arming yourself with instructions and take the correct recommendations as a basis. But without the proper tool, the work will not be completed. In addition, wires and cables can have a different basis, the methods, respectively, differ.

Features of stripping insulation and problems in the performance of work

Before stripping insulation from wires, it is worth considering some of the nuances of the process. After all, the coating can be in one layer and several. The work is quick, but this requires a stripper.

If you do not go into details, many do not see difficulties in the procedure for cleaning the cable or wire from protection. But without sharp, sharp objects, work will not go smoothly. As a result, there is a possibility of violating the integrity of the wire itself. The following may happen:

- Gap formation in an unnecessary place.

- There is an opportunity to get hurt.

- Damage to the conductor itself.

All this is simply excluded if a simple and accurate instruction for implementation is taken into service. In addition, special tools are required. Do not rush, even if you have experience with the task. It is worth at least theoretically understanding how to remove the insulation from the wires with a tool.

What kind of wires are there?

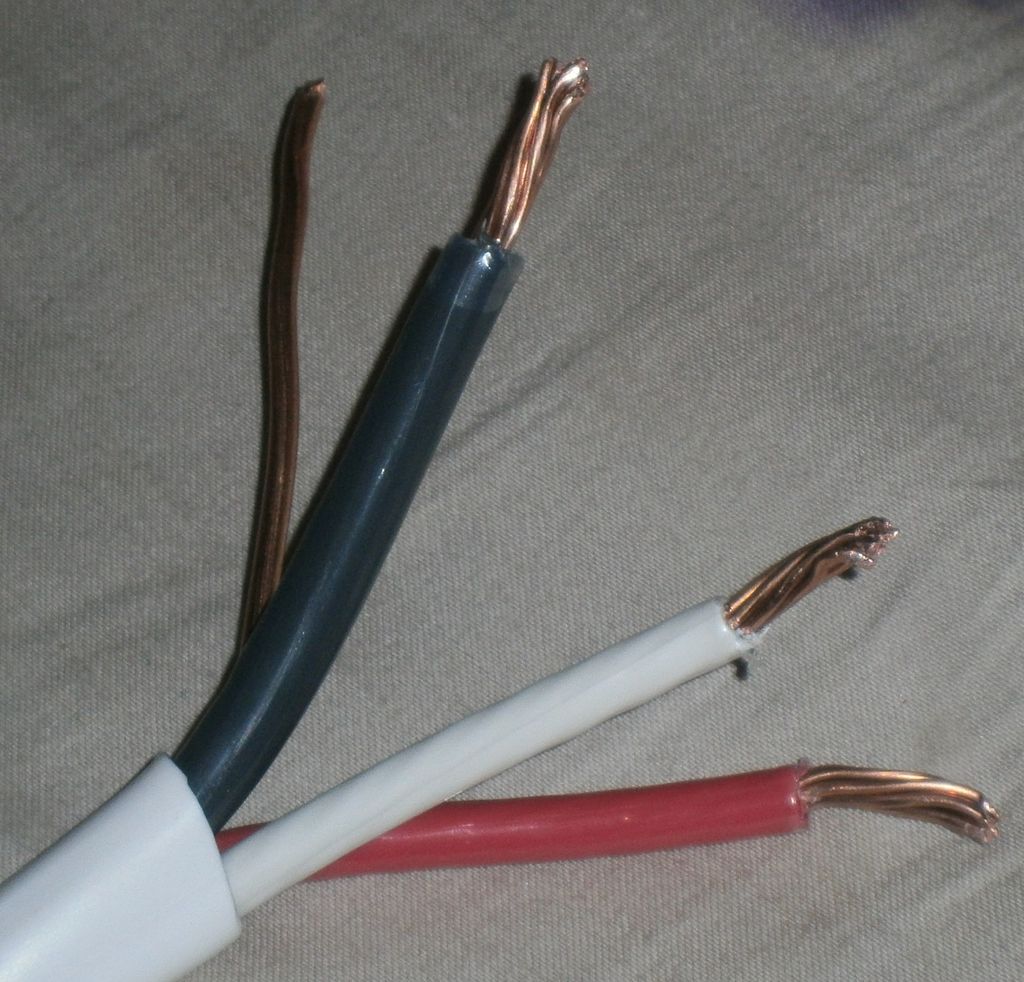

There are two main cores used in the process - copper and aluminum. If you remove the insulation, then with each kind you have to be careful and not rush. If we talk about strength, copper retains its integrity longer than aluminum. Below we consider the properties and characteristics of each.

Aluminum:

- Density is expressed in t / m 3 . More than 2.6.

- Resistance to frequent bending is not.

- Create a multi-wire core will not work.

- The resistivity is negligible.

Copper:

- Density is expressed in t / m 3 . More than 8.8.

- Resistance to frequent bending is present.

- Create a multi-wire core.

- The resistivity is good.

From these data we can conclude that the copper wire is better and its conductivity is higher. But aluminum does not have a high level of reliability, so it is used less often. In the process of stripping will have to be very careful. Therefore, before removing the insulation from the copper wire, it is worth making a small notch and preparing the appropriate tool. There are not many options for working with cables and wires, it is important to choose not just the suitable method, but the effective one.

What methods are effective?

Most of the skills when removing the protective layer from a cable or wire comes with time and practice. Especially when you need to do cleaning on the thinnest wire.

The main thing is to correctly choose the degree of application of effort and pressure on the tool. In addition, the speed of work and the final result depend on the direction of movement. You will have to understand how deep the main core is. It will depend on it whether it is damaged or not. Before you remove the insulation from aluminum wires or copper, you have to figure out what kind of material is inside.

The simplest work options:

- The use of clerical or ordinary knife. If you chose the first option, then you should not take too large, they are uncomfortable to work. Pressing should not be maximum, as their blade is quite sharp. A simple knife should have a narrow blade and high-quality sharpening.

- Using side cutters. This is a convenient design, it looks like scissors, but more durable and sharp. They are sold in any hardware store, although many always have it at hand.

- Burning. This is another good option and less traumatic. For this, it is necessary to apply high temperature so that the winding melts. If you want to make a small exemption, then this method is ineffective, since a rather large area is burned.

- Using a stripper. Such a tool is chosen by professionals.

Each method has its own characteristics. Further we will consider these methods in more detail.

Knife application

How to quickly remove insulation from wires? This is the most common and effective method, but it is very traumatic. When you need to handle a small number of wires at home, this option is quite suitable. The main thing that you need to know is at what angle the tool should be guided. You can not make circular movements, because it is completely ineffective. Because this option is very likely to cut the main working core. After this, the wires will become unusable.

The tilt angle is as sharp as possible so that the blade does not penetrate deeply into the body of the wire. Only slight glide is allowed. You should choose the position “on your own” - such conditions are safe for the worker and for the cable itself.

Electrician's knife

An electrician's knife is the most convenient tool. He has a heel, so holding it is quite simple. The core is protected as much as possible, the hands are safe, and stripping is effective. This is the answer to the question: "How to quickly remove the insulation from a copper wire or aluminum?"

Bokorez - effective help

This is a metal tool with comfortable handles. But most often the work is done by masters. In this process, you need to know what force to use, otherwise damage to the main core is possible. Electricians know how to carry out the stripping process. Side cutter is used in several cases:

- When the cable is too thick, biting is done in several places along the entire length, and then the insulation is removed by hand. This option is quite suitable for inexperienced people. But the cuts must be done carefully so as not to violate the integrity of the main cable.

- It is necessary to draw a strip along the entire length, and then remove the main winding in a downward direction.

- Through a distance of 3 centimeters, cuts are made with a side cutter. Then you need to remove the winding in small pieces.

These are the simplest options for people without experience and more. Wizards easily work with this tool. This option will help to easily remove the insulation from the wire for scrap. In order not to damage the main core, it is worth holding the sharpened jaws in the opposite direction of pulling and removing insulation. This allows you to not break anything and do the job quickly.

Today on sale there are such wires on which the manufacturer in the process of creating makes special notches so that the insulation is quickly removed. Therefore, before removing the insulation from a copper wire, it is worth considering it: perhaps even tools will not be needed.

Burning

This is the easiest way when you need to remove the insulation for putting wires. It is also the most effective method, if the inside is made of polyvinyl chloride veins. When you need to process a small area, then use a lighter or soldering iron. Under thermal influence, the winding softens, and it simply comes off the wire. With a small thickness of the winding, this option is the most effective.

There is one drawback - the presence of smell. Therefore, work must be done in a room with fresh air. Toxic emissions during the firing process adversely affect the state of the body.

What is a stripper?

It is such tools that help to do the procedure quickly and efficiently. But not every cable is suitable for such work. The cross section must be at least 0.2 mm. On sale or at the masters you can find various types of devices:

- Manual stripper without add-ons. Its use is similar to working with a side cutter: make notches, after which the winding is removed. But not for each section, this option is suitable.

- Semiautomatic device. At the core there is an adjustment lever that adjusts the degree of pressing, after which, when the handles are closed, the main process of stripping begins.

- Machine. This is the best option because it is based on several functions - notching, stripping, crimping conductors.

As a result, this method brings many positive aspects. The main thing is that cuts of the main core are completely excluded. In the end, you can call this method the best. It is the stripper that allows you to properly remove the insulation from the wires without damaging the core.

Cable check

When work is underway to get rid of the winding, you need to carry out actions in a clear sequence. Each cable has its own characteristics. Work on the copper cable should be carried out in the following order, since it has two layers of PVC insulation:

- The power is disconnected from the electricity.

- During the installation of the outlet, only a strictly defined area must be cleaned. 15 cm is enough. A person without experience should not reduce this distance. A side cutter is used for this procedure.

- The upper part is notched and carefully removed.

- The required length is set on the stripper, after which the phase and neutral conductors are placed in the tool. A full sweep is done.

This is the whole scale of work, after which it is necessary to fix the socket. It is not difficult to make such a procedure, although mistakes are often made. The wire breaks, and you have to clean up further.

How not to perform crimping?

Experts believe that removing insulation from cables and wires is not so simple. As a result, many mistakes are made that lead to a snack of the main core. The main reason is the use of the wrong tool. Therefore, there is a special list of those violations that should be known not only to beginners, but also to masters:

- When the top layer is removed and it needs to be cut, often the master chooses the wrong angle, which leads to incisions in the main core. Even a slight, inconspicuous notch of the insulation of the conductive cable leads to a short circuit, and sometimes to the complete failure of the entire device.

- Misuse of side cutters. They have a sharpened side and a dull side, often the choice is made on the wrong side. As a result, there is a sharp slip along the wire, which leads to excessive tension and squeezing, and this is already a violation of the integrity of the main core.

- A knife with a heel is convenient, but it must be clearly guided, namely, choose the angle of inclination. The mistake made leads to the fact that the main cable is cut. A violation of secondary isolation is already more serious problems.

Everything happens due to an illiterate choice of instrument. But there are other problems: a frivolous attitude to the procedure for cleaning the winding of the main cable or wire. Before you remove the insulation from a thin wire, you should know what actions you will have to perform, and do everything carefully and in a clear sequence. There are situations that the distance for work is minimal and risking is unacceptable.

We repair earphones

A common problem when using headphones is a violation of the integrity of the wire. To restore it, you need to choose a simple clerical knife for work. The procedure takes place in several stages:

- Need to find a breakdown.

- Remove the upper winding by making a neat longitudinal cut.

- Connect the components and insulate them.

How to remove the insulation of the wire from the headphones?

You can apply a sheet of sandpaper. Its granularity does not matter (the main thing is to perform work on the front side of the element). We set the edge of the wire on sandpaper and press the soldering iron on top. He will melt our winding. Further, its remains can be removed by hand. As a result, we get a wire without insulation. After that, you can connect using the same soldering iron. This is not a lengthy procedure, but everyone can come to a positive result. Do not experiment, each tool does its job. When working with wires and cable, they use a sharp knife and stripper, in other situations it is worth choosing the appropriate devices.

Conclusion

So, we examined how to properly remove the insulation from the wires. As you can see, there are different tools and ways. One has only to choose the most suitable and follow the instructions.