Not so long ago, exclusively cable or water varieties were used as floor heating systems. However, recently becoming more common infrared warm floor under linoleum, reviews about it you can read in this article.

Positive Features of Infrared Underfloor Heating

An infrared warm floor under linoleum, reviews of which can be both positive and negative, is quickly installed. According to consumers, this became possible due to the lack of the need for additional work. Such systems can be mounted on any rough coating, without equipping the screed, as well as without preparing the base. Such a warm floor under linoleum, reviews of which can be read in the article, has a thermostat. All consumers who already use similar systems note that they like it, because such an addition makes it possible to set the temperature that is needed. All buyers who care about the health of their households most often choose infrared systems for the reason that their work does not change the humidity of the surrounding air. Underfloor heating under linoleum on a wooden floor provides a comfortable temperature near the floor surface, while at the ceiling it is much lower. Experts say that the infrared floor has a therapeutic effect on the body, and also helps to prevent a number of diseases.

Negative Infrared Reviews

Infrared underfloor heating under linoleum has some disadvantages. Among them, one can single out the fact that the surface of the system can simply be damaged. That is why during operation it is especially necessary to carefully treat the base of the system. A number of consumers refuse to purchase these floors due to a fire hazard, which increases with improper use and damage to the film. Under one of these conditions, a fire may occur. Owners of houses and apartments who wish to install additional heating equipment mention that the rather high cost of infrared systems makes them tilt their choice towards more attractive solutions at a cost.

Features of the installation of infrared heating systems

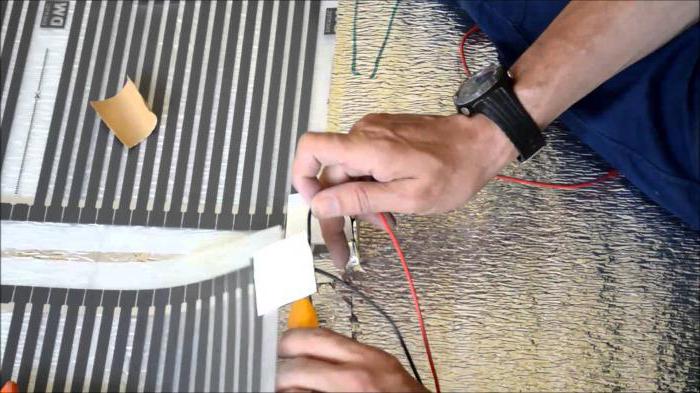

Such underfloor heating under linoleum with your own hands can be installed. At the first stage, it is necessary to plan the location of the system based on the area of the room. In this case, it is necessary to exclude the space occupied by furniture, including a strip whose width is 200 millimeters. The latter is located along the walls. The area that turned out to be unoccupied should be measured and the required amount of film in square meters should be determined. Now it is possible to lay a heat-reflecting screen on the rough coating, which will allow directing radiation into the room. The formed joints should be glued with tape. Now the master should lay the infrared film, which is drawn down by copper bars. If there is a need to make cutting, then you should be guided by special marking, so you need to cut exclusively in sections. The connection must be made using wires and clips, which are attached on one side of the section, while the other should be insulated using special material supplied in the kit. If you prefer infrared underfloor heating under linoleum, installation should be done using a certain technology. At the next stage, it involves connecting a thermostat, for this it is necessary to install a separate outlet. Now electrical wires are connected, which will go from the electric meter. A circuit for connection is attached to the controller. Then the temperature sensor should be connected, wires should be drawn from the temperature controller to the closest located section of the film. Scotch tape will help to glue the wires from the bottom to the graphite sections. Before completing the work, it is necessary to connect the warm floor, connect it to the network and analyze whether the system works correctly. Only after can the topcoat be laid. For safety reasons, experts recommend installing fiberboard between the decorative layer and the warm floor.

Positive feedback on the film field

Film underfloor heating under linoleum can also be laid. He has his positive and negative sides. According to home masters, such equipment is quite easy to install. The process will take about 3 hours. Many refuse to use water floor heating for the reason that the room can only be operated after the screed has fully gained strength. This can not be said about film systems: they can be used immediately after installation, which is very popular with the consumer. Buyers also note the efficiency that manifests itself during installation and during operation. This lies in the fact that the installation does not imply additional costs for the purchase of mastic, glue or screed. You can purchase a film underfloor heating under linoleum, the installation of which can be done independently, given the area of a certain room. Analyzing the reviews, you can see that the described heating systems save energy. Thus, during operation, the savings reach 20%. It should be noted and the safety of film systems, which are often compared with electric underfloor heating. Films have gained such high popularity also because of durability. If certain sections or bands are affected, then they will fail, while the entire system will continue to work without interruption. Film underfloor heating under linoleum, the installation of which is carried out according to the same technology as described above, is not subject to corrosion. The manufacturer gives a guarantee for 15 years.

Negative reviews

Customers who have never encountered the need for installation work of the type described, note that installation requires certain skills. That is why quite often you have to turn to specialists, which entails additional costs. The film underfloor heating under linoleum, reviews of which will help you make the right choice, has another drawback: in the event of a breakdown, you have to dismantle the entire decorative coating. Sometimes this is quite problematic, including when the room has heavy and oversized pieces of furniture.

Features of mounting thermal film

Experts recommend laying heat-reflecting material like an isolon on the surface of a subfloor or screed. Film underfloor heating under linoleum, reviews of which allow consumers to make the right choice, must be mounted in accordance with the methodology, which in the next step involves laying the thermal film. After it you need to cover with polyethylene. Then you can lay the fiberboard or plywood. When choosing a material with a heat-reflecting effect, it is forbidden to use those that contain aluminum foil. When laying thermal film, do not provide an air gap. Connection points must be isolated.

Advantages of electric underfloor heating

Electric underfloor heating under linoleum today remains the most popular heating system among alternative solutions. Among its positive quality characteristics, consumers note environmental cleanliness. Among other things, consumers are attracted by the fact that during installation there is no need to lay pipes and connect them to a source of hot water, as is the case with water floors. Such systems are very economical, and they can function in automatic mode.

Security

The warm floor under linoleum, reviews of which will help you with installation work, must be laid strictly according to technology. So, you can use electric heating floors as an auxiliary or main type of heating the home. Masters who have already been engaged in installation work more than once emphasize that the production of electric floors uses modern materials and multi-level protection, which acts as a guarantee of safe operation and long, as well as reliable operation.

Negative reviews

If you decide to choose an electric warm floor for linoleum, then you should know about its shortcomings. You can familiarize yourself with them by reading this article. Thus, it can be distinguished that it is impossible to arrange such systems without additional thermal insulation at the locations of the heating pipes, which are oriented horizontally. Among other things, when mounting a heating loop with a single-core cable, it is necessary to take into account electromagnetic interference in the room, taking into account safety measures. This is not always possible for a person who has not previously encountered such work. Mobile underfloor heating for linoleum, reviews about which are often quite positive, can be selected if you plan to rearrange in the near future.

The impossibility of a change of scenery

After the stationary system described above has been laid, it will not be possible to move furniture to new places, this is fraught with overheating and failure of the heating elements. This fact in most cases forces the buyer to refuse to purchase an electric floor heating system. If you decide to lay an electric underfloor heating under linoleum on a wooden floor throughout the house, then you will need to install a separate temperature control unit in each room, this may also seem problematic.

Features of installation work

Before the start of the process, it is necessary to select and prepare the place where the control unit will be located, and otherwise - the thermostat. It is recommended to place it on the wall, which will be free for access. It should be no higher than 100 centimeters from the floor. An appropriate hole should be prepared for the housing. The power wires and the ground wire should be brought to the unit. It is important to run a perpendicular groove for laying wires that will lead to the heater cable. If you will be laying an electric heated floor under linoleum, you should definitely read the reviews about it before purchasing. At the next stage, a heat-insulating layer is laid, the thickness of which should not be less than 2 cm. The cable must be laid along the mounting tape, following a pre-selected scheme. It can be, for example, a spiral or a snake. In the process of laying, contact and crossing of the cable should be excluded. Pair the power wires and the heating cable with a sleeve. However, it is important to consider that in the future the screed will be laid.

Final work

The temperature sensor must be inserted into a corrugated plastic tube. Before laying an electric underfloor heating under linoleum, the reviews of which we provide in this article, it will be necessary to analyze the integrity of the cable cores with the help of a tester and a megger. Now the master is pouring the screed, the thickness of which can vary from three to five centimeters. After the concrete has hardened, it is possible to connect the grounding and supply wires to the corresponding elements on the block of the control unit.

Conclusion

Water underfloor heating under linoleum, reviews of which are quite positive, can also be laid. However, the work on its arrangement is considered much more time-consuming. This is the main disadvantage of these systems. However, if such manipulations succeed, then electricity will be saved. In the event of a breakdown, you still have to dismantle the screed, which not all home masters like.