Organization of the production process is one of the most important aspects of building strategic plans for any organization. It depends on whether the company will make a profit, whether its products can differ in the required set of qualities. Before creating a new production or launching a new product line, a thorough planning process is carried out for each operation. Types of production and their characteristics will be discussed in detail below.

Features of the organization of the production process

Considering the types of production and their technical and economic characteristics, it is first necessary to understand why it is so important for each enterprise to correctly find the optimal approach to the production of finished products. The fact is that the further choice of production methods, as well as its control and planning, depends on this. The characteristics of the organization of the production cycle depend on the type of production. It can be continuous or periodic.

Based on the selected method of manufacturing products, decisions are made on the rational use of machinery and equipment. Based on this, a list of the necessary units is compiled, as well as their equipment. The type of production is directly related to the peculiarities of the movement of objects of labor during technological cycles, as well as to the management and planning system of the organization.

General characteristics of the main types of production allows you to make the right decision in the process of forming and equipping the shops and structural divisions of the company, to calculate and optimize the load level of each workplace. Each type of enterprise has its own characteristics when organizing the production process. Given them, you can choose the optimal approach to the organization of all processes.

Under the type of production should be understood categories that differ in the breadth of the nomenclature, stability and regularity of output. They reflect the characteristics of the internal connections of all the elements that are involved in the process. Each category of production reflects the regularity of operations for each workplace.

Influence of type of production

The type of organization of the production process significantly affects the entire technological cycle. There are mass, single and mass production. Often, in the conditions of the same enterprise, each of the listed types is used. This is due to the need to synchronize all processes. For example, in machine-building industries, their characteristics and types of organization of work processes may be different. At the plant with a mass approach to the manufacture of products, both medium and small series operations are performed. If the plant is engaged in the production of single products, some technological cycles can be organized according to the serial type. This is a normal and common practice.

The type of organization of production processes may depend on various factors. One of the determining factors is the industry in which the organization operates. On what type of technological cycles prevails in the enterprise, the course of the process of creating finished products depends on the boundaries of the rational use of technological equipment. It also allows you to determine which personnel with which level of professional training should be involved at each stage of the production cycle.

The organizational characteristics of the types of production make it possible to make the right decision on choosing one or another level of standardization and unification in the manufacture of products. If a mass approach is used in the release of goods, unification and standardization are of the greatest importance. If the production is single, original parts may be produced. Their level in the total mass of finished products can reach 100% for some enterprises.

Depending on the type of production chosen, the composition of the equipment is also chosen. Its use may vary significantly over a period of time. The structure of operations of a unit of equipment is largely determined by the type of production. Preparatory, final and basic procedures will occupy different shares in the total amount of working time.

Unit production

Considering the characteristics of various types of production, you can delve into their features and the rules of organizing the work process. One such category is unit production. In this case, the products are manufactured in a small, limited number of copies. This type of production is also called piece.

This approach to the organization of the technological cycle allows the company to produce a huge list of different products. Their nomenclature is huge. Each product is available in limited quantities. Moreover, the list of finished products is unstable. In this case, it is practically impossible to apply standardization in the manufacture of such products. The proportion of original goods in the total mass of production is significant. Finished products can differ significantly in important ways (for example, in appearance, functionality, design, etc.).

One of the main characteristics of a single type of production is the discontinuous nature of the technological cycle. In order to produce a unit of goods, it will take a lot of time. Equipment can be universal. During assembly, a lot of manual labor is expended. At the same time, staff should have universal skills.

Unit production is widespread in the manufacture of equipment for the steel industry, the energy sector, as well as in the chemical industry and the service sector. This is often a creative process.

Most often, the workshops of such industries are divided into sections in accordance with the type of technological processes. In the process of manufacturing products, significant labor (significant laboriousness, high level of staff qualification) and material resources are expended. This helps to increase the cost of finished products. In it, a significant part belongs to staff remuneration. In some cases, this cost item is about 25% of the total cost of production.

Mass production

Considering the types of production and their technical and economic characteristics, special attention should be paid to serial production. This is the most common approach to organizing the manufacturing process. In this case, the constancy of release is observed. In this case, products are manufactured in batches or series. A certain regularity of release is established.

The annual range of serial types of production is wider than the monthly. This approach allows you to organize a fairly rhythmic release of products. It is manufactured in large quantities. This allows us to apply unification during the technological cycle. Parts are obtained standardized or normalized. They enter the ranks in large batches. This helps to reduce the cost of production.

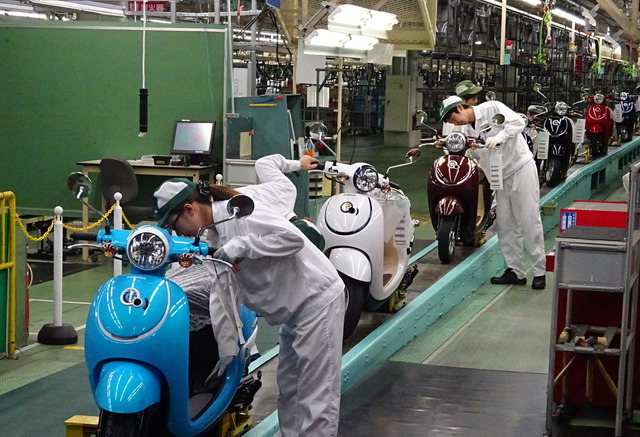

This type of production is often found in machine tool industries, in ferrous metallurgy. In this case, a highly specialized approach to the organization of labor is applied. Each workplace is characterized by the performance of certain operations. This allows workers to master the tool and fixtures well. In this case, the manufacturing process is of high quality, as the master can hone his skills, improve the techniques that he applies in the course of his work.

Considering the economic characteristics of the types of production, it can be noted that with the serial method of production, it is possible to draw up a cyclically repeating schedule. This greatly simplifies the control and process control procedures.

Varieties of serial production

Serial production can be small-, medium- and large-scale. The main characteristic of type 1 production is the tendency to a single way of creating finished products. Small-scale production is a transitional stage from a single to a serial type. In this case, the products are made in batches, but they are very small.

This type of manufacturing is popular, for example, in mechanical engineering. Now it has become fashionable to produce complex, unique equipment in small batches. Such a special order allows you to sell finished products more expensive. This is one of the main motivating factors for a certain category of buyers to make an expensive purchase.

Modern technologies make it possible to introduce features of continuous production into small-scale production. On the same line, for example, it is possible to produce several different types of products. This allows you to reduce the consumption of working time in the process of reconfiguring the operation of the unit.

Considering the characteristics of the serial type of production, it is also worth paying attention to the large-scale approach to the manufacture of products. This is also a transitional form. This category is between serial and mass production.

Large-scale production involves the release of products in significant batches. Moreover, the period of their manufacture is quite long. This type of organization of production is characteristic of enterprises that manufacture individual products or sets for subsequent processing. Standardization and unification in this case are high. The cost of production can be reduced due to the effect of the scale of production.

Mass production

Studying the characteristics of the types of organization of production, it is worth paying attention to the mass approach to manufacturing products. In this case, the range of finished products is strictly limited. They are homogeneous in purpose, appearance, design and technical parameters. Production is ongoing. Finished products can be produced simultaneously or in parallel.

For a long time, such manufactures produce the same type of product. The entire workshop or even the factory produces only one or two types of products. In this case, it becomes economically feasible to use not only unified, but also interchangeable elements when creating the design. Each unit of production does not differ from the previous and subsequent parts. Only slight differences in configuration may be observed.

Each unit of production is manufactured in a very short time, which is measured in minutes. At the same time, the nomenclature of both monthly and annual production coincides. This approach to production allows you to introduce a high degree of mechanization and automation of the entire production process.

The main characteristics of the mass type of production are most acceptable for machine-building enterprises, as well as for production of special machinery, agricultural equipment. This method of organizing the manufacture of products is also observed in light industry.

The equipment used in the mass production is characterized by high productivity, automation. The equipment in this case is special. Jobs are distinguished by narrow specialization. Operators operate here. The work of highly qualified employees who are responsible for maintaining the correct operation of the automated line is also used.

Comparative characteristics

To consolidate information on the presented approaches to the organization of production, it is necessary to consider the comparative characteristics of the types of production. It is presented in the table below.

Factor | Mass | Serial | Single |

Interchangeability | Full | Average | None (fit possible) |

Release Repeatability | Always | Periodically | Never |

Equipment | Mostly specialized | Partially universal | Universal |

Nomenclature | 1-2 species | Limited to series | Unlimited |

Cost price | Low | Average | High |

Unit Location | Chain | Group and chain | Group |

Tool | Special | Universal and special | Universal |

Securing operations for machines | The same operation is performed on each piece of equipment. | Some operations are performed on one unit. | No special fastening |

Workers qualifications | Mostly low, but there are highly qualified staff | Average | High |

Based on the data listed, conclusions can be drawn about the features of each approach to the organization of the production process.

Production Organization Methods

Knowing the economic characteristics of the types of production, we can conclude about each approach to the organization of output. Based on this information, production methods are also chosen. Under this concept it is necessary to mean methods of technological cycles. They are characterized by a number of signs. One of the most important is the relationship between the order of placement of production equipment and the sequence of each operation.

The method of organizing the production process determines the arrangement of units that take part in the technological cycle. Also in this concept includes the sequence with which this or that production task is performed, and the time of its duration.

There are three methods of production, which are called single, batch and flow approach.

Description of Methods

Types of production and their characteristics determine the choice of method of manufacturing products. Depending on how the movement of parts occurs at workplaces, discontinuous and continuous types of movement are distinguished.

The direct-flow type of movement of objects of labor is organized in a sequential order. Products move sequentially from one processing step to another in the direction of the technological cycle. If this process occurs not only straight-through, but also continuously, such a process is called in-line.

If the issue is organized sequentially, but intermittently, it is called partioned. In this case, only a certain number of parts are manufactured (batch). This method is advisable to apply to enterprises with a wide range of products.

With frequent changes of equipment, as well as significant breaks between operations, the process of individual production of products occurs.

Production planning

Having considered the basic methods and types of production and their characteristics, the enterprise management can make the right decision about choosing one or another approach to organizing the production process.

One of the possible options may be the development of an operational functional diagram. In this case, all the resources that take part in the technological cycle are grouped according to the type of work they perform. Most often used for small-scale production.

Sometimes a decision is made to create a fixed positional layout. The product in this case remains motionless. As necessary, production resources are supplied to it, which is typical for construction.

In mass production, a linear pattern of movement of objects of labor is used. This allows you to divide the process into several small operations.

Having considered the types of production and their characteristics, it is possible to organize technological cycles as efficiently as possible. This contributes to obtaining products with defined functions.