The position sensor of such a detail as a crankshaft can rightfully be called the main element in a car that functions on a par with the engine. The main objective of this type of sensor is to control fuel injection, synchronize fuel resources and the entire ignition system. That is why, if some kind of malfunction occurs in the operation of such a part, then the machine simply cannot “activate”, and the motor does not turn on. Also, as it moves, the position sensor regulates the distribution of fuel, informs the driver about the speed of the crankshaft, continuing to synchronize the operation of the motor itself. Such sensors come in different types, they all work on different principles, which, first of all, depend on the model and technical features of the machine.

The most common is an inductive (or magnetic) crankshaft position sensor . It functions due to the fact that a magnetic field is formed around it (which is why the name of the mechanism), which interacts with the synchronization tooth. A similar type of sensor is also used by many drivers as a gauge of the speed with which the car is moving. It is easy to use, very resistant and not affected by external factors. The second type of sensor is the Hall effect, whose work is also based on the interaction of teeth with a magnetic field. This sensor is often used as an indicator of the ignition distributor. A more advanced and relatively new type of sensor is the optical one, which is based on the conversion of the light flux into a voltage pulse.

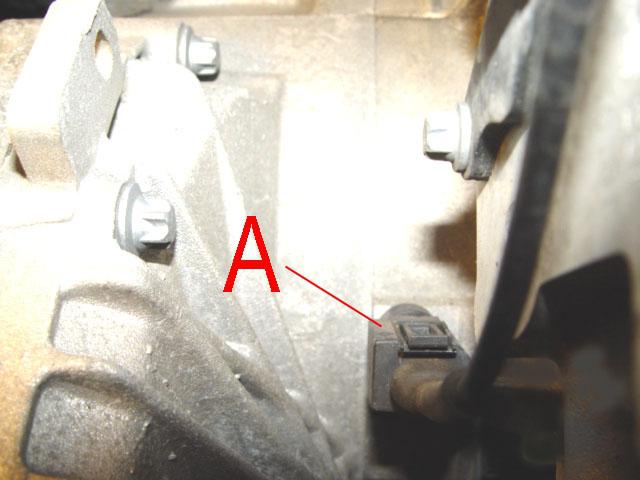

The position sensor, whatever it is, is mounted to the on-board circuit using a long wire. It usually has the same equipment as any other car sensor. Therefore, no one should have problems installing it. However, it is worth noting that when attaching the crankshaft sensor, it is necessary to leave a gap of 1 to 1.5 millimeters in size between it and the gear pulley, since otherwise this mechanism will not be able to generate the necessary magnetic field, therefore, the position sensor will not work.

The crankshaft position sensor can be damaged in the event that the repair was carried out by an amateur (and by mistake the details of the car were touched). Also, the cause of damage can be the ingress of foreign objects into the gap between the teeth and the sensor itself, which will lead to a halt in its operation. Correcting the situation is possible only by replacing this device with a new one. That is why it is advisable to always have a replacement sensor with you, which can be installed at any time.

In order to determine in advance whether the position sensor in the machine is working, you just need to connect an ohmmeter to it and measure the resistance. If its indicators range from 800 to 900 Ohms, then the mechanism is normal. Otherwise, such a sensor simply will not be able to function, and any driver will immediately see an alarm. As a rule, a sensor error is displayed in the form of a code with the number 35 or 19 in the control buffer of the system.