The choice of dentures is now quite large, but with incomplete tooth decay, the most popular dental crowns that allow you to refuse removal. They are made in different ways, from different materials, and sometimes it is difficult to choose the right option.

What is a crown and why is it needed?

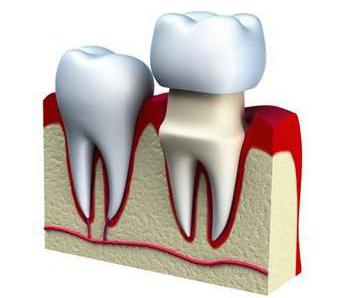

A crown is a type of fixed denture. Outwardly, it repeats the shape of the tooth and during installation it becomes indistinguishable from healthy teeth. It is used for incomplete tooth decay to restore its masticatory functions and aesthetic appearance, as well as to prevent further decay. Crowns are distinguished depending on the material for their manufacture. They are metal, cermet, plastic and ceramic. Metal clinics are rarely used in modern clinics, as they have an unaesthetic appearance, and are completely unsuitable for prosthetics of the front teeth.

Ceramic have a natural appearance. This is the most expensive type of crowns, they are made of zirconium oxide. Plastic crowns are mainly used as temporary prostheses, as they do not have durability and wear resistance, are easily subjected to mechanical damage and fail. This is the cheapest kind. Ceramic-metal crowns combine beauty and strength; they are most popular in comparison with other types because of their practicality. Dental crowns are also distinguished by the method of manufacture: sometimes the crown is stamped and cast.

Stamped crowns. Manufacturing principles

The manufacture of stamped crowns has been used for over a hundred years, many dentists consider this process a relic of the past, but, nevertheless, it is still used, since it is very cheap. Stainless steel is used to make cylindrical billets of different diameters, from which metal crowns are stamped on special machines. Such a product should have some qualities for proper installation and comfortable wearing.

The stamped crown must fit clearly in the size of the tooth, cover it tightly, without gaps and voids. Otherwise, it will provoke inflammation of the gums, as a result, it can lead to atrophy. For a more snug fit of the crown to the tooth and its fixation, special dental cement is used. The crown should not go deep into the gums, this can cause gum disease, such as periodontitis. In addition, it must correspond to the shape of a healthy tooth, so as not to violate the integrity of the row, and be sized to avoid injury. The product is designed to restore the function of the tooth.

Stages of manufacturing a stamped metal crown

- first, a cast of the jaw is taken, all completely.

- Next, the desired product is modeled.

- receiving stamps

- the crown itself is made

- the product is polished and polished

- the finished crown is put on a previously prepared tooth and fixed with cement.

Indications and contraindications for the use of stamped crowns

Stamped metal crowns use:

- With incomplete tooth decay. At the same time, the tooth is grinded to the desired size, all its defects and carious lesions are eliminated in order to exclude further destruction.

- If removable prostheses, for example clasp, or bridges will be installed. To protect the supporting teeth, crowns are installed.

- To restore a decayed baby tooth

There are some contraindications to their use:

- Bruxism (grinding of teeth, in which enamel is destroyed).

- Complete tooth decay, in which there is nothing left to save.

- Infectious diseases of the oral cavity.

Pros and cons of stamped crowns

Advantages of stamped crowns:

- Preparation of the tooth does not require much time, turning is carried out to a minimum, since the crown walls are thin. This is especially important if the product is attached to a healthy tooth, which will be the support for a removable denture.

- This is a medical procedure that allows you to maintain a healthy tooth and avoid extraction.

- A stamped crown can be used in cases where other types of prosthetics are not possible (for example, the use of implants cannot be carried out due to diabetes mellitus or another patient’s disease).

- This is a cheap method of manufacturing and prosthetics, so it becomes a salvation for people with low incomes.

The disadvantages of stamped crowns:

- Using for a long time leads to abrasion of the crown and its failure. Subsequently, the product will have to be replaced with a new one.

- The cement on which the crown rests resolves over time, which leads to a loose fit to the tooth and gum. This, in turn, can lead to damage, tooth decay and tooth decay due to ingestion of food.

- If the tooth is completely destroyed, the crown will not help to perform chewing functions.

- The stamped bridge has brazed parts that shorten its life.

One piece crowns

The modern casting method made it possible to produce high-quality thin-walled crowns. One-piece crown is used to restore the shape of a damaged tooth, its preservation, as a support for bridges and removable dentures. It is cast from a cobalt-chrome alloy; as a result, a whole product is obtained without adhesions. Even when creating bridges, soldering of elements is not required, the design is poured out entirely. Such crowns may have various manufacturing options.

- Ordinary crown without spraying, polished metal.

- Gold-plated crown. May cause an allergic reaction. With prolonged use, the spraying is erased.

- One-piece plastic crowns. They have a cast metal frame and a plastic overlay to give an aesthetic appearance to natural teeth. With prolonged or careless wearing, chipping of plastic is possible.

- Cermets. The most expensive type of crowns, has durability and a natural look.

Indications for use of cast crowns:

- Significant tooth damage.

- Pathology of the shape of the teeth or its location.

- Malocclusion.

- Anomaly in tooth size.

- Support for removable and bridges.

- Prevention of abrasion, bruxism.

The advantages of cast crowns

- The possibility of one-piece manufacturing of not only individual crowns, but also bridges, which ensures the strength and durability of the products.

- Durability. The wearing of such crowns can last up to 10 years if the quality of the material and installation are performed at a high level.

- Quick and easy to manufacture.

- The one-piece crown is made individually for each tooth and fits perfectly into the dentition without causing discomfort in wearing.

- The accuracy of the design allows you to tightly install the crown without gaps, which protects against bacteria and food under it.

- For front teeth, crowns with a dusting or facing for aesthetic appearance are possible. The stamped crown does not provide such an opportunity.

Disadvantages of cast crowns

- In preparation for the installation of the crown, a rather large layer of a healthy tooth is grinded.

- Casting crowns must be ultra-precise, otherwise installation and wearing will be problematic.

- When taking hot or cold food, discomfort is possible due to the high thermal conductivity of the material.

- The price of such products is much higher than that of stamped crowns.