In crisis conditions, many people are placed in a rather tough position, starting with ordinary citizens and ending with representatives of big business. The automotive market turned out to be the most prone to various problems, and difficulties began to appear on it at the end of 2014, because from that time experts have noted an increase in the life of various cars. Everyone today is trying to maximally delay the moment when his old, tested car will need to be changed to a new car using a variety of means, one of which is the deoxidation of Laurel. Reviews about this product can be found mostly positive, but in order to finally decide on a purchase, you need to understand the principle of action and the advantages of this tool.

Nowadays, car service is a place where drivers prefer not so much to fix various malfunctions as to prevent problems related to the age and mileage of the car. An intermediate means of such prevention is specialized auto chemical goods.

How did she appear?

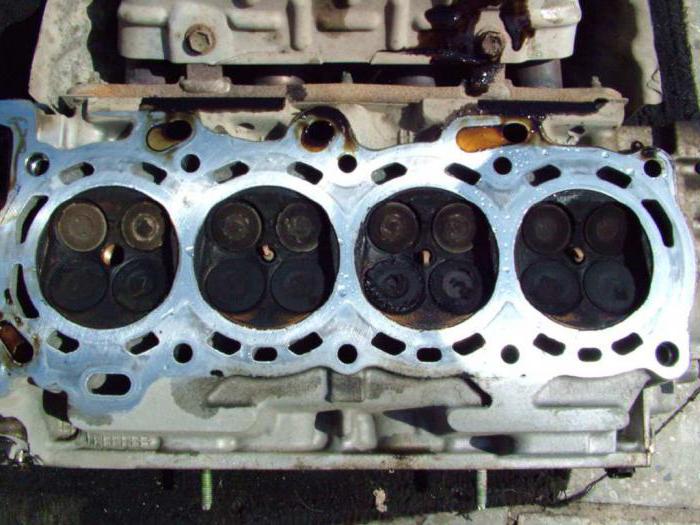

Immediately after various cars began to spread actively in the USSR, each owner knew that periodically it was necessary to clean the piston rings from various contaminants. At the same time, fuel in those days burned much worse compared to the current one, and sludges formed rather quickly on the surface of parts. Today, everyone can make the clinker “Laurel” to get rid of such malfunctions, then you had to come up with something else.

The oil was also much less quality, so it oxidized rather quickly on the cylinder walls, forming a film and falling into the piston grooves. Among other things, in the process of fuel combustion, soot gradually formed, mixing with this film, thus forming extremely resistant solid deposits blocking the operation of the pistons.

Motorists tried to deal with such pollution by any available means, for example, they left kerosene in the engine overnight, and over time they began to use special solvents more often. Desperate car owners did not stop at the risk of being left without a vehicle at all. In addition, the effectiveness of such formulations was practically absent, and today many motorists are not afraid to experiment to the detriment of themselves. Some have completely forgotten that it is necessary to carry out such a procedure, relying entirely on additives that are added to modern oils, as well as relatively high fuel standards.

Since that time, automotive chemistry has made significant progress, and today many people use Laurel disintegrating fluid for these purposes, but it is also not omnipotent, as many might think.

How does LAVR help defer overhaul?

It is natural that overhaul of the engine for most motorists is the most terrible event, since it is a huge cost, and the need for such a procedure suggests that the machine is currently absolutely unsuitable for use. That is why, in order to avoid such situations, a special ripping is used by Laurel. The reviews suggest that the savings with this tool are quite tangible, because today the cost of major repairs of most middle and budget class cars is around 50 000 rubles, while the drug costs only 400. But this tool is not a panacea, eliminating the need for repair, but only prevention, so it will be useful to understand whether serious savings are really achieved.

New car service trend

It is worth noting the fact that today even many car services have gradually begun to include in their price list a service such as Laurus coking. The reviews of experts on this subject indicate that this is a rather profitable activity, since not all motorists can independently carry out this procedure, despite the fact that they have this opportunity. For professionals, this is a non-laborious procedure, and it can easily be carried out on the street, since it does not provide for the need to place the machine in the service. Thus, many companies provide themselves with genuine gratitude of customers and their more active flow, and, consequently, profit. All this is provided by deoxidation by the Laurel. The reviews of the masters suggest that the flow of cars for this procedure is almost continuous. The reason is that it needs to be carried out every year or every 30,000 km, which means that the person who has already completed it is guaranteed to become a regular customer of this service.

What are the benefits?

The Lavr fluid for engine sizing is absolutely safe for various equipment, therefore its use completely eliminates the possibility of any conflict situations or complaints from customers.

The procedure is extremely easy to use, so the owner of such a business does not have to allocate additional funds to train the masters - just read the instructions for the drug and follow it correctly. If the “Laurel” liquid for carburizing the engine is dosed correctly, the consumption of the drug in a car service can even be registered.

It is worth noting that such a procedure was carried out by Soviet car enthusiasts, but LAVR is the first company that launched the drug on the mass market, and at the moment there are no funds that would surpass ML 202 in their technical characteristics. A separate advantage of this tool is that that the car service does not need to allocate additional costs for equipment, since all the tools necessary for the procedure are in the package of the drug itself, which is another significant property.

Interesting facts about sizing

Despite the fact that it has been possible to make the coking process “Laurel” for a long time, motorists have formed a lot of different prejudices and stereotypes regarding this procedure, many of which are not true. That is why further we will try to make out a few key points.

Modern engines do not need sizing

Of course, over the past few years, the situation with oil and fuel has improved significantly, because in Soviet times, few could even get started without using a blowtorch, but despite this, the problem of coking not only did not disappear, but it was also seriously aggravated. The technology has become more advanced, the gaps between the grooves and the piston rings have decreased, but this ultimately led to greater vulnerability of modern systems. Also, an insignificant layer of deposits ultimately leads to engine malfunctions, deposits accumulate more and more over time, and problems become more serious - compression decreases, detonation occurs, wear is accelerated, and then serious damage occurs. If you are not going to spend money on major repairs, the correct Laurel coking can help.

Versatility

Of course, "Laurel" is a fairly effective tool, but in reality it is far from universal and in the first place performs a repair and preventive function. If the engine is too worn out, then no procedures other than a complete overhaul and replacement of parts will not be able to return the system to working condition.

Additives and Flushing

Many people believe that these procedures save from any problems, so carrying out sizing is not necessary. In fact, it is most effective to remove various deposits through "immersion" when the coking composition is poured directly into the cylinders. At the same time, getting to the technological holes is far from easy, and you have to use special tools, as well as create comfortable conditions (it is better not to do such work on the street in bad weather). That is why it is recommended to disengage the engine during the scheduled replacement of spark plugs or oil.

The amount of fluid affects cleaning

The fluid volume must be sufficient to wet the pistons well. In the predominant majority of cases, the volume of preparations is calculated so that it is enough to carry out the processing of each cylinder. Of course, if you pour 50-60 ml more than the standard dosage, this will not affect the efficiency of the engine, but pouring the product in large quantities is still not recommended.

The fluid should perfectly clean the surface.

“Laurel” is a preparation that cleanses medium and high degrees of coking, but it often happens that in old engines the deposits are already so “bored” with the parts that they are kept like cement mortar, and even cleaned such systems Not recommended. Also worth noting is the fact that too caustic solutions can cause engine damage.

But in any case, LAVR is considered a more effective tool compared to analogs and standard solvents.

How is this procedure carried out?

Now let's talk about how the Laurel fluid is used. Raskoksovka (instruction below) does not take so much time, if you correctly follow the instructions for this tool and select the desired dosage. The procedure itself is done as follows:

- The engine warms up to operating temperature, which should be more than 70 ° C.

- The ignition system is turned off. To do this, you can remove the connector from the ignition coil or Hall sensor. Thanks to this, you can get rid of the possible ignition of the vapors of this drug, as well as the breakdown of various elements of the system.

- The spark plugs are removed. If the procedure is carried out in a diesel engine, glow plugs or nozzles are removed.

- Pistons are set in a position close to the middle, while the crankshaft must be rotated for the pulley mounting nut or using the drive wheel with the gears engaged. To determine the position of the piston, you can use a long probe inserted through the process hole.

- Pour “Laurel” liquid in equal volume into each cylinder through a syringe. Then close the process openings so that a “steam bath” forms in the combustion chamber.

- Now you have to wait. For the express procedure, you need to wait at least one hour, but with severe coking, the exposure time of the drug should increase up to 12 hours. So that the fluid can more effectively seep into the lower part of the cylinders, periodically you can move the pistons in different directions.

- Clear the technological holes. The remaining fluid is removed with a syringe, after which the cylinders are purged with compressed air. Now you will need to fully depress the accelerator pedal, and then rotate the engine shaft with the starter two or three times in five seconds. At the same time, it is recommended to cover the technological holes with some dense cloth so that the Laurel ring scouring agent does not splatter.

- Install dismantled parts and assemblies. Be sure to carry out additional verification of the assembly.

- Start the engine and leave it idle for 5-10 minutes to reach operating temperature. It should be noted right away that short-term smoke may appear, since the liquid for oxidizing the Laurel rings remaining inside will burn out, and this smoke is harmless to the catalysts.

- Clean the engine with a preparation designed to flush the lubricant system, or with a special LAVR preparation.

- To completely get rid of soot, it is recommended to drive the first few kilometers with slightly oversized speeds.

This is proposed by the company "Lavr" raskoksovka. The instruction is extremely simple, and the work may well be carried out by experienced motorists and in garage conditions, so if you are confident in your abilities, you do not need to turn to car services.

What do they write in the reviews?

For most people, the Lavr company product - a tool for sizing - liked it very much, and they note the positive effect of its use. Among the advantages of using this fluid are the following:

- Significant reduction in oil consumption with active pedaling (about 10-20%).

- After the coking of the diesel engine by Laurel was carried out, the engine began to work quieter for many. In gasoline units, the same effect is found, and vibration also disappears.

- The equipment has become obedient at high speeds and acceleration, and also has a more pleasant sound.

Some people who used the composition of the "Lavra" for coking, say that they did not see any noticeable effect, and such tools do not particularly help with the problems that have arisen, and the rings are easier to replace than perform the specified manipulations.