Laying tiles is a technologically challenging task, so its implementation is often trusted by professionals. But if we are talking about a small finishing area and there are at least basic skills in working with cladding, then it makes sense to save on third-party services. One of the most important stages of the process will be the preparation of tile fragments for laying in roundabouts and corners. Accordingly, a tool for processing the material is required. How to cut tiles? Mechanical tools such as a tile cutter and electrical equipment help in this matter. The choice of a technical assistant depends on the characteristics of the tile itself and the amount of work.

Work with a manual tile cutter

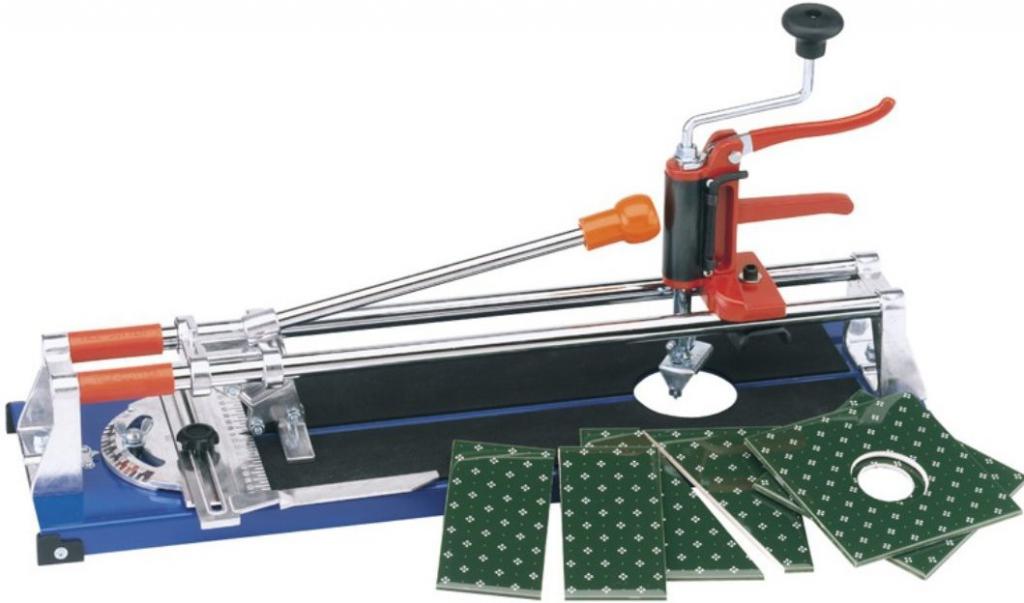

The optimal solution if you plan to serve an average volume of material, while ensuring high quality cutting. Of course, getting smooth edges and the speed of the process will depend on the skill of the performer, but the design completely helps the owner. The tile cutter is based on a small bed with a frame, guides and a cutting roller. The tool is controlled by the handle. First, the external surfaces of the structure and the workpiece itself should be cleaned. The latter is placed in a special grip, and then made cutting. If we cut the tiles with a manual type tile cutter, then initially we should focus on a one-time pass. This means that the roller applies the risk only once, otherwise it is very likely to get a curve or a chipped edge. But the operation does not end there. Such a tile cutter only causes a dissection line, but the fragment is separated separately by breaking with special nippers.

Features of cutting with electric tile cutter

For one-time homework, acquiring such a model is not always advisable, but be that as it may, in a large farm, it will help in the future with the processing of other tile materials. This type of tile cutter is distinguished by the presence of a massive bed (usually on racks), an electric motor and a saw blade that directly performs cutting. How to cut tiles on such equipment? Initially, the workpiece is marked along the cutting line, after which it is fixed on the worktop of the unit with a clamping bar. Some models of the electric tile cutter allow you to change the position of the tile on the desktop, adjusting it in detail to the optimal cutting direction. Then the operator turns on the engine and starts the rotation of the disk. Equipment settings usually allow setting the rotation speed with the speed of movement of the workpiece under the working head. Such a tool can work with tiles about 40 mm thick. By the way, for a manual tile cutter, this maximum is 15-20 mm.

Can I use a glass cutter?

In technical terms, not the most successful solution to the problem, but it has a big plus - affordability. Just for 300-500 rubles. You can purchase a good roller model of a tool provided with a miniature reservoir for supplying oil to the working head. How to cut tiles at home with a glass cutter? The cutting technique is the same as in the classic glass cutting. At the preparation stage, marking along the clipping path is applied. Next, the workpiece is placed on a stable and rigid surface and is clamped with one hand. Moreover, the tile should be fixed by means of a metal ruler or plank, the back edge of which will converge with the intended line. After this, the second hand (usually the right one) is applied with a glass cutter to the risk. The pressure should be as high as possible, which will facilitate the subsequent fault operation. To do this, use tile cutters or special tongs that allow you to scrape strictly along the line with minimal damage.

How to cut a tile "grinder"?

A kind of combination of machine tools and mobile hand tools. With the same electric tile cutter, the angle grinder is similar in high power, which allows you to cut off even parts of porcelain stoneware. But for this you should equip the tool with a diamond disk. Preparation for work is carried out according to the rules described above with the cleaning of tile surfaces and marking. The most important and responsible condition for high-quality and safe work will be reliable fastening of the workpiece. It is advisable to place it on a metal workbench using complete grips for clamping. Next, we cut the tile with a “grinder” so that the saw blade rests gently and smoothly against the target surface along the marking line. Powerful devices do not cause any special problems and easily perform cutting, but it is important to consider that the "grinder" already in the process of work leaves a lot of dust. For this reason, a construction vacuum cleaner with the immediate elimination of processed products, or a respirator that protects the respiratory system should be provided.

The use of jigsaw

This tool is mainly used for working with wood. Its functional element is represented by a thin file, which allows to form an accurate and accurate cut. For tiles, choose a model of a jigsaw with a power of at least 1500 watts. Moreover, the saw blade should also have an appropriate purpose for rigid materials, otherwise it will break off on the solid structure of the workpiece. At home, we cut the tiles on special supports - so that their height matches the outlet length of the file. The movement should be unhurried. Moreover, for a quality cut, it is recommended to moisten the tile section along which the marking passes before work. With sufficient power, the jigsaw will provide smooth edges without serious defects, but this applies only to thin tiled material.

How to perform curly cuts and holes?

For a curvilinear cut in the presence of experience, even a “grinder” can be used. The quality of the result will depend on the ability to guide and work out the cut in the turning areas. But the jigsaw described above is best suited for figured cutting, since it gives a minimum of vibrations, is well controlled and does not lead the saw to the side. But how to cut tiles to form small holes? For this, two tools can be used - the same mechanical tile cutter with a “ballerina” or a hole saw. As for the first option, it is an optional addition in the form of a circular cutter, which can form holes with a diameter of 20-80 mm. Moreover, the work is carried out manually according to the type of a conventional drill - through the handle, a force is applied to the cutter, which rotates and thereby forms a circular cutting. In turn, a circular saw is a nozzle for the same grinder or its modification. That is, the cut is performed due to a gear crown rotated by an electric motor.

Differences in working with different tile materials

In most cases, ordinary home craftsmen deal with ceramics and, in particular, with tile. These are clay products with a thickness of 15-25 mm that have undergone heat treatment. This group of materials can be serviced without any problems with a hand tool - from a glass cutter to a tile cutter. We cut the same tile by directing a functional organ, maintaining the direction of the intended contour and not depressing the pressure along the entire line. But sometimes it requires processing of thick and solid materials, which can be used in laying tracks and flooring. It can be stone agglomerate and porcelain stoneware. In this case, you can not do without an electric tool. Two basic rules should be followed - reliable fixation of the workpiece itself and tight control of the housing leading the cutting nozzle.

Cutting Safety

At high volumes of work, it is advisable to use safety glasses. They will prevent dust and small fragments from getting into your eyes. Particular attention is paid to hand protection. Gloves, for example, should only be used when preparing tiles. Work operations are performed without them, since there is a risk of a hook on the cutting body. In any case, the hands should be away from the cutting line. If ceramic tiles are cut with an angle grinder, it is important to monitor the equipment overheating. In electric tile cutters, a separate water supply function is provided for cooling the working equipment, but in the case of the “grinder”, you will have to take small breaks and lower the temperature of the saw blade with the workpiece yourself.

Conclusion

Cutting tiles in and of themselves is only part of the general preparation for facing work. And so that the result justifies itself in terms of aesthetic properties, the processed fragments should be sanded. From the accuracy of the basic cutting will depend on the amount of finishing refinement. How to cut tiles with a tile cutter so that the edges meet the requirements for the coating? The rejection rate at the cut-off stage is reduced not only by the competent handling of equipment and tools. Consumable lubricants are also of great importance. At a minimum, wetting in plain water will increase the accuracy of the cutter. Technical oils and kerosene are also used to work more efficiently with glass cutters and tile cutters.