To assess the operational properties of products and determine the physical and mechanical characteristics of materials, various instructions, GOSTs and other regulatory and recommendatory documents are used. Destruction testing methods for a series of products or material samples of the same type are also recommended. This is not a very economical method, but effective.

Characterization

The main characteristics of the mechanical properties of materials are as follows.

1. Temporary resistance or tensile strength is the stress force that is fixed at the highest load before the destruction of the sample. The mechanical characteristics of the strength and ductility of materials describe the properties of solids to resist irreversible shape changes and fracture under the influence of external loads.

2. The conditional yield stress is called the stress when the residual deformation reaches 0.2% of the length of the sample. This is the least stress while the sample continues to deform without a noticeable increase in loads.

3. The long-term strength is called the greatest stress at a given temperature causing the destruction of the sample for a certain time. The determination of the mechanical characteristics of materials focuses on the ultimate units of long-term strength - failure occurs at 7,000 degrees Celsius in 100 hours.

4. The conditional creep limit is the stress that causes a given elongation at a given temperature for a certain time in the sample, as well as the creep rate. The limit is considered to be metal deformation in 100 hours at 7,000 degrees Celsius by 0.2%. Creep is a certain rate of deformation of metals under constant loading and high temperature for a long time. Heat resistance is the resistance of a material to destruction and creep.

5. The endurance limit is the greatest value of the stress of the cycle when fatigue failure does not occur. The number of loading cycles can be set or arbitrary, depending on how the mechanical tests of the materials are planned. Mechanical characteristics include material fatigue and endurance. Under the action of loads, damage accumulates in the cycle, cracks form, leading to destruction. This is fatigue. And the property of resistance to fatigue is endurance.

Tensile and compression

Materials that are used in engineering practice are divided into two groups. The first is plastic, for the destruction of which significant residual deformations should appear, the second is brittle, collapsing with very small deformations. Naturally, such a division is very arbitrary, because each material, depending on the conditions created, can behave both as brittle and plastic. It depends on the nature of the state of stress, temperature, strain rate and other factors.

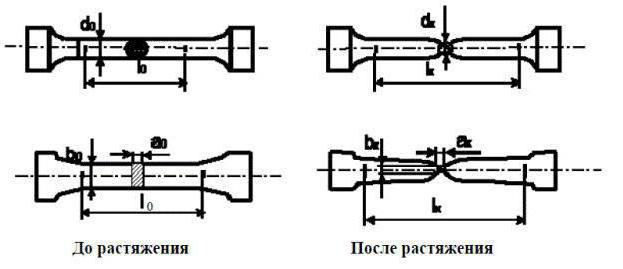

The mechanical characteristics of materials under tension and compression are eloquent in both ductile and brittle. For example, mild steel is tested in tension, and cast iron in compression. Cast iron is brittle, steel is ductile. Brittle materials have greater resistance to compression, while tensile deformation is worse. Plastic ones have approximately the same mechanical characteristics of materials under compression and tension. However, their threshold is still determined by stretching. It is by these methods that one can more accurately find out the mechanical characteristics of materials. The tensile and compression diagram is presented in the illustrations for this article.

Fragility and ductility

What is ductility and fragility? The first is the ability to not collapse, receiving residual deformations in large quantities. This property is crucial for critical process operations. Bending, drawing, drawing, stamping and many other operations depend on the characteristics of ductility. Plastic materials include annealed copper, brass, aluminum, mild steel, gold, and the like. Much less ductile are bronze and duralumin. Almost all alloy steels are very weakly plastic.

The strength characteristics of plastic materials are compared with the yield strength, which will be discussed below. The properties of brittleness and ductility are greatly influenced by temperature and loading speed. Fast tension gives the material brittleness, while slow tension gives it ductility. For example, glass is a fragile material, but it can withstand prolonged exposure to stress if the temperature is normal, that is, it shows the properties of plasticity. And low-carbon steel is ductile, however, under shock sharp loading it appears as a brittle material.

Vibration method

The physicomechanical characteristics of materials are determined by the excitation of longitudinal, bending, torsional, and other, even more complex types of vibrations, depending on the size of the samples, forms, types of receiver and pathogen, methods of fastening, and schemes for applying dynamic loads. Oversized products are also subject to testing using this method, if you significantly change the method of application in the methods of application of load, excitation of vibrations and their registration. The same method determines the mechanical characteristics of materials when it is necessary to evaluate the rigidity of large-sized structures. However, with local determination of material characteristics in the product, this method is not used. Practical application of the technique is possible only when the geometric dimensions and density are known, when it is possible to fix the product on supports, and on the product itself - converters, certain temperature conditions are needed, etc.

For example, when changing the temperature regimes, one or another change occurs, the mechanical characteristics of materials when heated become different. Almost all bodies expand under these conditions, which affects their structure. Any body has certain mechanical characteristics of the materials of which it consists. If in all directions these characteristics do not change and remain the same, such a body is called isotropic. If the physicomechanical characteristics of materials change - anisotropic. The latter is a characteristic feature of almost all materials, just to varying degrees. But there are, for example, steels where the anisotropy is very small. It is most pronounced in natural materials such as wood. In production conditions, the mechanical characteristics of materials are determined through quality control, where various GOSTs are used. The heterogeneity estimate is obtained from statistical processing when the test results are summarized. Samples should be numerous and cut from a particular design. This method of obtaining technological characteristics is considered quite time-consuming.

Acoustic method

There are a lot of acoustic methods in order to determine the mechanical properties of materials and their characteristics, and all of them differ in the methods of input, reception and registration of oscillations in sinusoidal and pulsed modes. Acoustic methods are used in the study, for example, of building materials, their thickness and state of tension, with flaw detection. The mechanical characteristics of structural materials are also determined using acoustic methods. Numerous various electronic acoustic instruments are already being developed and mass-produced, which allow recording elastic waves and their propagation parameters both in a sinusoidal and in a pulsed mode. On their basis, the mechanical characteristics of the strength of materials are determined. If elastic vibrations of low intensity are used, this method becomes absolutely safe.

The disadvantage of the acoustic method is the need for acoustic contact, which is far from always possible. Therefore, these works are not too productive, if you urgently need to obtain the mechanical characteristics of the strength of materials. A huge influence on the result is exerted by the surface condition, geometric shapes and dimensions of the test product, as well as the environment where the tests are conducted. To overcome these difficulties, a specific problem must be solved by a strictly defined acoustic method or, on the contrary, to use several of them at once, it depends on the specific situation. For example, fiberglass plastic lends itself well to such an investigation, since it has a good propagation velocity of elastic waves, and therefore through sounding is widely used when the receiver and emitter are located on opposite surfaces of the sample.

Flaw detection

Flaw detection methods are used to control the quality of materials in various industries. There are non-destructive and destructive methods. Non-destructive are the following.

1. To determine cracks on surfaces and imperfections, magnetic flaw detection is used. Areas that have such defects are characterized by dispersion fields. You can detect them with special instruments or simply lay a layer of magnetic powder on the entire surface. At the places of defects, the location of the powder will change already upon application.

2. Flaw detection is also carried out using ultrasound . The directional beam will be reflected (scattered) in different ways, even if there are any discontinuities deep inside the sample.

3. Defects in the material are well shown by the radiation research method , based on the difference in the absorption of radiation by a medium of different densities. Used gamma flaw detection and x-ray.

4. Chemical flaw detection. If the surface is etched with a weak solution of nitric, hydrochloric acid or their mixture (aqua regia), then in places where there are defects, a net appears in the form of black stripes. You can apply a method in which sulfur prints are taken. In places where the material is heterogeneous, sulfur should change color.

Destructive methods

Destructive methods here are already partially disassembled. Samples are tested for bending, compression, tension, that is, static destructive methods are used. If the product is tested with variable cyclic loads on impact bending, dynamic properties are determined. Macroscopic methods paint a big picture of the structure of the material and in large volumes. For such a study, specially polished samples that are etched are needed. So, it is possible to identify the shape and location of grains, for example, in steel, the presence of crystals with deformation, fibers, shells, bubbles, cracks and other alloy heterogeneities.

Microscopic methods are used to study the microstructure and detect the smallest defects. Samples in the same way are pre-ground, polished and then subjected to etching. Further testing involves the use of electrical and optical microscopes and X-ray analysis. The basis of this method is the interference of rays that are scattered by atoms of matter. The characteristics of the material are monitored using x-ray analysis. The mechanical characteristics of the materials determine their strength, which is the main thing for building reliable and safe structures in operation. Therefore, the material is checked carefully and by various methods in all conditions that it is able to accept without losing a high level of mechanical characteristics.

Control methods

For non-destructive testing of the characteristics of materials of great importance is the correct choice of effective methods. The most accurate and interesting flaw detection methods in this regard are defect inspection. Here it is necessary to know and understand the differences between the methods of implementing flaw detection methods and methods for determining the physical and mechanical characteristics, since they are fundamentally different from each other. If the latter are based on the control of physical parameters and their subsequent correlation with the mechanical characteristics of the material, then flaw detection is based on the direct conversion of radiation that is reflected from the defect or passes through a controlled environment.

Best of all, of course, is comprehensive control. Complexity consists in determining the optimal physical parameters by which it is possible to identify strength and other physical and mechanical characteristics of the sample. And at the same time, an optimal set of control tools for structural defects is developed and then implemented. And, finally, an integral assessment of this material appears: its performance is determined by a whole range of parameters that helped determine non-destructive methods.

Mechanical tests

With the help of such tests, the mechanical properties of materials are checked and evaluated. This type of control appeared a long time ago, but still has not lost its relevance. Even modern high-tech materials, consumers quite often and fiercely criticize. And this suggests that the examination should be carried out more thoroughly. As already mentioned, mechanical tests can be divided into two types: static and dynamic. The former checks the product or sample for torsion, tension, compression, bending, and the latter for hardness and toughness. Modern equipment helps to perform these not too simple procedures efficiently and to reveal all the operational properties of this material.

A tensile test can reveal the resistance of the material to the action of a constant or increasing tensile stress. The method is old, tested and understandable, used for a very long time and is still widely used. The sample is stretched along the longitudinal axis by means of a fixture in a testing machine. The stretching speed of the sample is constant, the load is measured by a special sensor. At the same time, elongation, as well as compliance with its applied load, is controlled. The results of such tests are extremely useful if you need to create new designs, because so far no one knows how they will behave under load. Can only suggest the identification of all parameters of the elasticity of the material. Maximum stress - yield strength determines the maximum load that a given material can withstand. This will help calculate the margin of safety.

Hardness test

The stiffness of the material is calculated by the modulus of elasticity. The combination of fluidity and hardness helps determine the elasticity of the material. If in the technological process there are operations such as broaching, rolling, pressing, then the amount of possible plastic deformation is simply necessary to know. With high ductility, the material will be able to take any shape at the appropriate load. A compression test can also serve as a method for identifying safety factors. Especially if the material is brittle.

Hardness is tested with the help of an identifier, which is made of a much harder material. Most often, this test is carried out according to the Brinell method (a ball is pressed), Vickers (an identifier in the form of a pyramid) or Rockwell (a cone is used). An identifier with a certain force is pressed into the surface of the material for a certain period of time, and then the imprint remaining on the sample is examined. There are other fairly widely used tests: impact strength, for example, when the resistance of a material at the moment of application of a load is evaluated.