A fairly common crossover “Suzuki Vitara” and “Grand Vitara” began to be produced from the end of 1996. To complete the machine, various four- and six-cylinder engines were used. The most common was the two-liter J20A engine.

general information

The four-cylinder petrol J20A was used on various versions of the Suzuki Vitara, produced in time periods:

- Vitara Cabrio (ET, TA) - from December 1996 to March 1999

- Vitara (ET, TA) - from December 1996 to March 1998

- Grand Vitara (FT) - from March 1998 to July 2003

- Grand Vitara (JT) - from October 2005 to February 2015

- Grand Vitara Cabrio (GT) - from March 1998 to July 2003

The engine has cylinders vertically in a row with a displacement of 1.995 liters. Depending on the type of firmware of the electronic control unit, the motor develops power from 128 to 146 forces. The design potential of the J20A engine, which was inherent in the design, allowed it to last almost 20 years in production.

General device

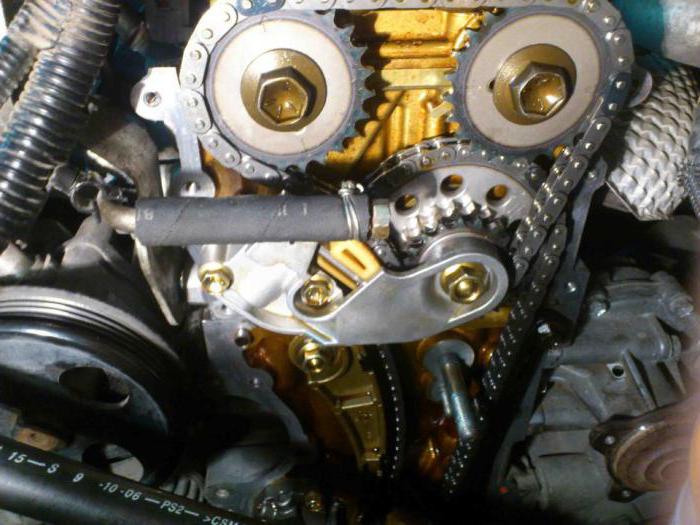

The main body parts - the head and cylinder block - are made of aluminum alloy. The valve actuator of the first generation of motors has hydraulic gap compensators, which greatly simplified maintenance. On later engines, from about 2003, shims are in the valve drive. Two chains are used to drive the gas distribution mechanism . Each of them has its own tensioner and its own vibration damper. On the front of the Grand Vitara J20A engine there is a multi-ribbed belt for the drive of various auxiliary units.

Execution options

There were several modifications of the J20A engine with different characteristics:

- Option used on the "Suzuki Escudo" of the second version and the "Mazda Levante". This option developed 140 forces with an exhaust rate of Euro-0.

- The first Suzuki Grand Vitara used a weaker version of the engine, which developed only 128 forces.

- Version for a complete set of "Suzuki" SX4 (GY), which is designed for transverse installation.

Benefits

Cars "Vitara" were equipped with a variety of engines with a working volume of 1.6 to 3.2 liters. But the most popular was the J20A engine, which provided the most favorable ratio of dynamics and fuel consumption. In general, the power unit has established itself as a completely reliable and unpretentious unit. A big plus of the engine is the possibility of using A92 gasoline.

The resource of the J20A engine largely depends on the attitude of the owner to the car and on the regularity of maintenance using quality materials. There are cases when cars with such an engine covered more than 270 thousand km without repair. Individual instances of cars with the J20A engine, according to owners, traveled up to 400 thousand km.

Almost all engine errors can be read on the instrument cluster. For this, the driver must perform the self-diagnosis procedure by closing the two terminals on the diagnostic connector. The resulting error codes must be decrypted in the tables.

Service

Maintenance of the Suzuki Grand Vitara engine consists of regular maintenance with the replacement of oil, filters and spark plugs. The plant recommends changing the oil in the J20A engine after 15 thousand km. But taking into account the operating conditions of the machines in Russia, it is recommended to reduce the oil change frequency to 10 thousand km.

According to the instructions, it is necessary to use Suzuki Motor Oil brand oil with parameters 0W-20 for the motor. Alternatively, many owners use 5W-30 synthetic oils. The capacity of the oil system is 4.5 liters, but when replacing the old oil does not completely go away, so 4.2-4.3 liters are poured into the crankcase.

One of the important aspects of engine maintenance is replacing the camshaft drive circuits . According to the regulations, such a procedure must be carried out after 200 thousand km. You should not neglect the replacement, as there are cases of unexpected open circuits. In this case, the engine did not have any symptoms warning the owner of the critical condition of the part.

Problems and malfunctions

The main engine problem is the camshaft drive circuit. The first problems with increased noise in the drive start from 140-150 thousand km. Typically, the reason lies in the hydraulic chain tensioner. A number of owners change only the tensioner, leaving the old chain. But such a solution, although it allows you to save money, can result in costly repair of the J20A engine. The old chain may already have signs of tension and the new tensioner will not be able to fully compensate for it. In this case, the chain slips along the teeth of the gears of the shafts or simply breaks, which shifts the valve timing. The result will be a collision of the pistons with the valves, which will lead to an inoperative state of the engine. Repairing such damage will block the cost of the circuit many times over. Therefore, many services recommend replacing the chain immediately when replacing the tensioner.

Another problem of the J20A engine can be oil burn, especially with a dynamic driving style. Many owners have experienced increased oil consumption during the initial engine break-in period. But then the flow came back to normal. During operation, it is necessary to remember such a "sore" motor and monitor the level. Neglecting this item may cause the engine to run in a mode of insufficient lubrication. In this case, you will need to repair the J20A engine with at least replacing the crankshaft liners. For replacement, there are liners of two repair sizes. In the worst cases, both the shaft and the piston group and the gas distribution mechanism will suffer damage.

A number of owners have a problem associated with a sudden loss of engine power. This starts the vibration and the motor stalls. In some cases, after 15-20 minutes it starts up, works for a while and stalls. Exhaust gas contains smoke and fumes of unburned gasoline. The cause of this behavior is a faulty crankshaft position sensor.

It is worth noting another malfunction that several owners of the 2-liter Vitar have already encountered. Over time, there is a subsidence of the shaft of the coolant pump deep into the body. At some point, the impeller blades begin to touch the body. At the same time, the motor makes extraneous sounds during operation. If the pump is not replaced in time, then the blades are abraded and the supply of coolant decreases. Because of this, overheating of the thermally loaded unit and head occurs, which leads to scoring and engine failure.

Chain Replacement Materials

One of the most difficult procedures when repairing the J20A engine will be replacing the chains. When replacing materials will be needed:

- Chain tensioner (number 12831-77E02).

- Chain tensioner (number 12832-77E00).

- The chain is small upper (number 12762-77E00).

- The chain is large lower (number 12761-77E11).

- Soothing device (number 12771-77E00).

- Soothing device (number 12772-77E01).

- Tensioner underlay (part number 12811-77E00).

- Tensioner Gasket (Number 12835-77E00).

- An epiploon on a forward part of a cranked shaft (number 09283-45012).

- Gasket on valve cover (part number 11189-65J00).

- Seals for fastening the valve cover (number 11188-85FA0) - 6 pcs.

- Candle well seal (number 11179-81402) - 4 pcs.

Chain drive gears usually do not require replacement.

Tools and materials

- Set of wrenches and heads.

- Torque wrench up to 150-200 N / m.

- Sealant for the front cover.

- Rags for wiping.

Work sequence

- Install the machine in the pit.

- Remove the expansion tank and plastic cover on the motor.

- Remove dipstick for oil level measurement.

- Remove the coils from the candles.

- Disconnect ventilation hoses from cover on unit head.

- Remove the head by unscrewing six nuts.

- The cover design has two bushings installed in the rear. They are best removed and put separately.

- Rotate the crankshaft by the pulley mounting nut to align the labels. One mark is applied to the pulley, the second to the crankcase.

- Remove the drive belt for auxiliary units.

- Release nut and remove crankshaft pulley.

- Remove the rollers for the pump and tensioner.

- Remove the 15 front-cover bolts.

- Remove the engine shield and unscrew the two more bolts securing the cover.

- Remove the air conditioning compressor.

- Disconnect the coolant hose at the front of the engine. The hose must be plugged with a wooden wedge or bolt.

- Remove the cover from the motor. The lid is centered on the unit with two guide pins.

- Check the valve timing on the old circuit. The keyway of the main shaft should coincide with the mark on the crankcase, the mark on the double intermediate gear should be directed upwards. In this case, the risks on the camshaft gears should coincide with the risks on the casting of the head.

- Remove chain tensioning mechanisms.

- Remove the camshaft gear bolts. To fix them from rotation there is a special flat with a turnkey hexagon.

- Remove the gears and the upper chain.

- Remove the intermediate gear and the main chain, as well as the gear from the toe of the crankshaft.

- Install new lower chain and drive gears back. In this case, the chain has links in blue and yellow. The blue link should be opposite the mark on the double gear, and the yellow link should be opposite the mark on the main shaft of the J20A engine.

- Install a new lower tensioner.

- Fit the camshaft gears and the upper chain. The yellow mark of this chain should coincide with the mark on the double gear, and the blue with the marks on the shafts.

- Install a new upper tensioner.

- Lubricate the entire mechanism with engine oil.

- Replace the shaft seal in the front cover and the candle rings in the valve cover.

- Install the front cover on the new sealant.

- Install a new gasket on the valve cover and mount it on the head.

- Install all removed parts. If the cover nut seals are damaged or lost, replace them with new ones.