Engineering communications are traditionally made of metal. Pipeline infrastructure of this type has many advantages, which are expressed in strength and durability. Nevertheless, the transition to plastic components made it possible to optimize the installation processes of the supply circuits and increased the resistance of the system to corrosion. Today, the installation of pipes made of cross-linked polyethylene is available to the ordinary home master even without the support of specialists.

Material Features

Crosslinked polyethylene should not be confused with ordinary plumbing plastic. It can be positioned as a modified polymer material, characterized by a complex structure of internal fibers. The technology of forming a three-dimensional mesh with longitudinal and lateral bonds is called PEX - with this marking, cross-linked polyethylene is presented on the domestic market. By the way, the most high-quality models are supplied by Bir Peks and Rehau. But even within the range of one manufacturer, technical and operational characteristics can vary depending on the modification. For example, installation of a pipe made of cross-linked polyethylene Rehau Rautitan is recommended to be carried out at a temperature of 90 ° C. But there are also heat-resistant versions suitable for working environments with a thermal load of about 200 ° C. In both cases, the material is optimally suited for domestic use in the infrastructure of underfloor heating and autonomous heating systems. Limitations relate mainly to contact with process fluids. Under normal operating conditions, cross-linked polyethylene can last up to 40-50 years, and this is its main advantage compared to other plastic products for plumbing.

What tool will be required for installation?

The advantages of PEX pipes include ease of installation. Without a special tool, the installation of pipes made of cross-linked polyethylene with your own hands can be realized using such means as:

- Construction scissors.

- Hand press.

- Wrenches of the appropriate format.

- Connecting sanitary fittings (fittings, expanders, adapters, etc.).

Particular attention at the preparation stage is given to the selection of fittings. Their type is selected for the installation method and operating conditions. For example, different models with a certain temperature resistance limit are used for cold and hot supply systems. According to the pairing mechanics, the fittings are divided into crimp and press fittings. Not without taking into account the dimensional parameters for a particular network. The use of adapters in diameter is preferably avoided.

Compression mounting

The method is quite simple, but responsible, since a lot will depend on the accuracy of the docking nodes. Do-it-yourself installation of pipes from cross-linked polyethylene by a compression method is carried out according to the following instructions:

- A crimping nut is selected strictly for the diameter of the pipe. It is put on an open cut so that the thread faces toward the connector.

- A split ring is installed. It is pulled and fixed so that the cut is removed at a distance of 1 mm.

- The pipe end with a seated ring and a compression nut is tightly and completely installed on the fitting fitting.

- The compression nut must be sealed to the optimum condition in which it can withstand operational loads. Tightening is carried out using wrenches, but without pulling so that the pipe does not deform.

Sometimes before installing a fitting, inexperienced craftsmen perform its corrective tuning, disassembling and chamfering. Similar actions are excluded.

Press-fit installation

This time, an expander is required to increase the diameter of one of the ends of the product. A step-by-step instruction for installing sewn polyethylene pipes by pressing it looks like this:

- A clamping press sleeve is put on the pipe. It is important to maintain the correctness of its position so that the side with the ring faces the inside of the contour, and not to the fitting location.

- The end of the pipe is stretched by a plumbing expander. During the operation, the diameter is increased, which will allow the end to fit onto the fitting fitting. The tool is inserted into the pipe, after which, by wiring the handles, stretching is carried out. The procedure is carried out all the way, but not abruptly so as not to leave deformed sections in the structure of polyethylene.

- The pipe from the cut side is gently pulled onto the fitting fitting. The fastening should be tight and brought to the stop.

After completion of installation, the finished structure is left in a calm state for several minutes. At this time, it can be slightly squeezed in order to exclude possible deformations. Further, the material will take on a new form, naturally adjusting to the given parameters.

Electric welding

This technology requires the use of a special coupling that has a thermal effect. This is the case when a household tool cannot be dispensed with. Nevertheless, if it is planned to install pipes of cross-linked polyethylene in large volumes with high requirements for the quality of the joints, this method will be most preferable:

- An electric- welded coupling is mounted on a pipe cut.

- A welding machine is connected to the terminals of the fitting.

- Voltage is applied to the fitting spiral, as a result of which the docking section will heat up to the melting state.

- When the connection elements are soldered into one structure, the welding equipment is turned off, and the polyethylene is left for the time of hardening.

This technology is commonly used in industry and utilities. An ordinary homeowner can be contacted because of the high-quality result of the pipe connection - the soldering practically eliminates the use of auxiliary fasteners, forming a reliable and durable seam.

What nuances are taken into account during the work?

There are universal rules for the installation of pipes made of cross-linked polyethylene, which should be followed regardless of the connection method:

- All materials from the pipe to tools and sanitary fittings at the time of work must be cleaned of dust, oil and dirt.

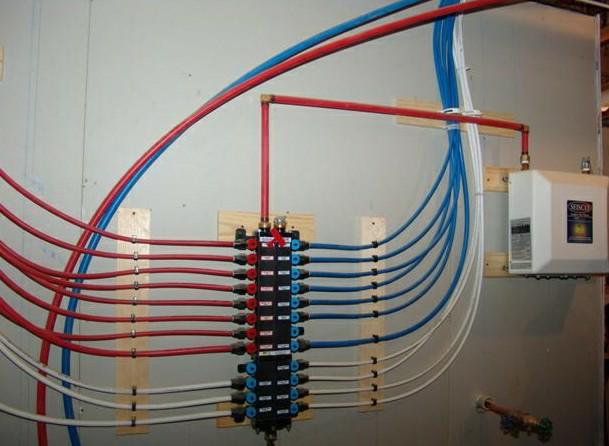

- In the complex assembly of the pipeline, output lines from the distribution manifold of the water supply system are always the first to join.

- In complex systems, a piping circuit diagram is drawn up before installation. On its basis, preliminary pipe cutting into segments is performed. Docking is performed with minimal distortions - you should maintain the direction of the contours horizontally and vertically.

Installation Quality Check

The main indicator of correctly made joints is the complete tightness of the joints. To check the assembly nodes, a compressor pressure tester is used - a kind of pressure blower that is installed on a specific section of the pipeline. The tactics of crimping depends on the system in which the pipes were installed. It is advisable to test cross-linked polyethylene for heating or water supply on separate segments between valves. The line gets rid of air and is filled with water, after which it is left under control of the crimping machine for several hours. Pressure readings are recorded before and after the procedure. If a difference was found between the readings, this may indicate a leak.

Are there any flaws in the cross-linked polyethylene communications?

When choosing material for a pipeline, several weak points of PEX pipes should be considered. Firstly, the structure of this plastic is characterized by high oxygen permeability, which contributes to the development of corrosion. Accordingly, the installation of pipes made of cross-linked polyethylene is best done with fittings made of the same polymers, rather than metal. Secondly, the material is sensitive to sunlight, so any contours on the street should have either insulation or a protective external frame.

Conclusion

In terms of installation, polyethylene pipes are optimally suited for domestic use. The material is easily cut, adjusted and combined with the most common plumbing fixtures in design and size. For example, the installation of "Rehau" pipes made of cross-linked polyethylene can be performed with standard rotary elbows, fittings and crimp rings. The manufacturer offers many of its own components for the assembly of the pipeline. It remains only to correctly design the structure, calculate the parameters of the assembly units and carefully carry out technical operations.