The technology of space heating due to underfloor heating is popular due to the optimal combination of ergonomic control properties and sufficiently high energy efficiency. So, if the design of infrared and electrical systems is expensive during operation, then water devices require minimal costs. The main costs are associated with the installation of a warm floor with a collector that requires special connection and configuration.

The principle of the water floor

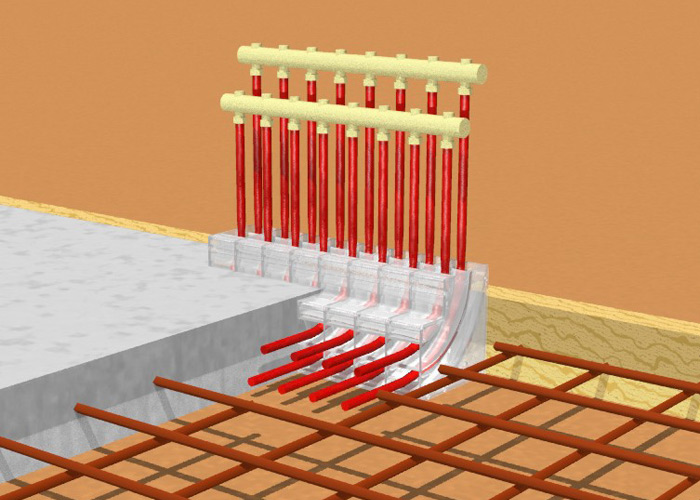

The infrastructure of this heater is formed by regulatory equipment, pumping equipment and heating circuits (pipes). The collector serves as a control mixer, in which the distribution and mixing of water flows - hot and cold. For physical control, two- and three-way valves are provided. In the process, the collector of the warm floor closes and opens them, regulating the flow of water along the laid out contours. The simplest two-way systems provide for connecting to two branches of main pipelines - from the boiler and to discharge cold water to the heat exchanger. Three-way systems additionally provide for the introduction of a weather-dependent sensor connection unit, which allows you to program the collector.

In the functional diagram, it can not do without a circulation pump that maintains sufficient pressure for stable movement of the coolant through the pipes. This unit pumps water up to a certain point until the temperature reaches a level set by the user. Also, as an option, the systems of collectors of underfloor heating can be supplemented by air vents and drainage devices that optimize the work process. But this applies mainly to equipment for large rooms from 200 m 2 , where high risks of contour airing are assumed.

How to choose a collector?

Mixing equipment for water floor heating is usually supplied in a single set with pipes, but if desired, you can purchase a collector and in a separate order for individual requirements. First of all, attention is paid to the material of equipment manufacturing. The best solution is stainless steel, which withstands sufficient temperature loads - more than 90 ° C, and also resists external mechanical stresses. Brass manifolds can be recommended as an alternative, but they cost more.

The next important parameter of the collector of the warm floor is the diameter, which varies from 16 to 32 mm. It is important to create a clear correspondence between the combs and pipes of the warm floor pipes. The heating circuits of the collector usually do not exceed 120 cm in length. Here you can vary the size depending on the number of mixer loops. Also, in addition to the collector, it will be useful to immediately provide thermostatic equipment and a pump if it is not in the set with heating circuits.

Installation Tools

At least in service, you should have a universal set of plumbing tools, tape measure and a building level. All this will be required for installation operations and preliminary marking of the installation zone of the collector.

Otherwise, the technical operations of the installation should be prepared according to the operating conditions and the connection of the collector group. The fact is that individual adjustment of the mixer with non-standard parameters may require the use of a pipe-cutting tool. The installation itself can be installed in a wall or in a floor structure. To do this, the mixing manifold for the underfloor heating is placed in an installation box, which, in turn, is attached to the wall or floor. Just for such a fixation you may need a hammer drill.

At the final stage, experts recommend performing pressure testing as well - accordingly, a pipe presser with instruments for measuring pressure will be needed.

Preparation for work

First you need to determine the future location of the collector installation. It should be as close to the floor pipe as possible. The optimal layout is from the edge of the wall 50-70 cm from the immediate heating zone.

Next, the question of whether the collector node of the heated floor will be placed in the mounting cabinet is decided. It can be left open (for ease of regulation) or closed in a metal box if long-term autonomous operation sessions are planned. At the next stage of preparation, the equipment is inspected. It is necessary to check the integrity of the pipes and manifold hoses, the tightness and reliability of the connections. The mechanics of the action of the shutoff valves in the control equipment is separately checked.

Manifold assembly for underfloor heating

The mixer can be mounted partially before installation or completely - after fixing the nozzles. Experts recommend constructing it separately, after having screwed the thermal head instead of the stopper plug. The assembly order will be as follows:

- On a branch pipe from hot water (the line from a boiler installation) the spherical crane is mounted. The connection is made with a three-way valve, if any. The direction of the connection will be indicated by the arrow on the surface of the device.

- The valve outlet is connected to the pipe from the water supply branch to the heating pipe. Do-it-yourself installation of the underfloor heating collector in this part is carried out with a hexagonal universal wrench, but so that the tightening is optimal and does not push the connection unit. Particularly the balance of the clamping force is important when working with polypropylene pipes and fittings.

- A circulation pump is installed in front of the valve. It is important to note that there can be two pumps - from the branch line and on the supply circuit. The connection of the second pump is justified if the pressure in the main line is too low.

- After the pump, a pressure gauge is attached to the direction of the manifold comb, which will indicate the pressure. It is desirable to arrange it so that the information panel is turned to the outside for the convenience of data control.

- A water distribution line for floor pipes is connected. A temperature sensor should also be located on this site. It is attached with plastic clamps.

- Moving in the direction of the flow of the coolant, it is necessary to establish a return water supply line. Using a simple plumbing tee of a suitable format (in diameter), a three-way valve should be connected to the return inlet.

- Through a tap in a regular tee, it is necessary to provide a return exit to the boiler.

- At the highest point of the collector, a Mayevsky crane is mounted, which will allow the release of excess air.

Ultimately, the assembly should ensure the connection of the collector with the inlet from the boiler, the inlet of the return flow line and the outlet of the mixed heat carrier to the warm floor.

How to connect a collector of a warm floor?

At the final stage of assembly, the collector pipes are directly connected to the supply channels using compression fittings. The connecting infrastructure includes a clamping ring, a support sleeve and a brass nut. It is not always possible to calculate the diameters of the various elements of the system corresponding to each other, therefore, adapter fittings should be prepared in advance. They will allow you to reliably connect multiformat nozzles and pipes, although plumbers still recommend minimizing the number of transition sections. Further, the installation of the collector of the warm floor involves the connection of a drain cock and a weather-sensitive sensor. In this part, the equipment is connected to the electrical wiring, for which a separate line with grounding and safety devices must be provided.

Installing the manifold cabinet

The design of the drawers for the mixer can be different, but most often they involve fastening to the walls due to mounting holes, as noted above. For fixing, two collector risers should be fixed on two brackets. Four holes are made in the wall - two on each side. Using hardware, brackets are installed, and then the back of the box is mounted. Do-it-yourself installation of the collector of the warm floor to the cabinet can be done with a screwdriver or screwdriver - as a rule, the attachment points are made in standard formats for fixing to hardware. Also, to save space, the designs of some drawers provide for the possibility of integration into wall niches. The collector housing is recessed into the prepared connector and hidden. The eyeliner is performed using knee tubes. But in this case, it is necessary to pre-wall the wall with a perforator with a shock function to a depth of 15-20 cm.

General recommendations for the installation process

To make the system as efficient, functional, and reliable as possible, several technical and construction tricks should be provided. These include the following:

- To obtain more complete information about the operating state of the system at a particular moment, water control sensors should be installed on each branch pipe. If the infrastructure is connected to automatic equipment with the possibility of programming, it will be possible to count on significant energy savings.

- For the convenience of mechanical control, servo mechanisms can be installed that allow closing individual collector lines through blackouts.

- When installing the collector of the warm floor, it is not recommended to use sealing tools like Teflon tape, tow, silicone mixture, mounting foam, etc. In extreme cases, you can use welding operations - both with metal elements and with plastics.

- Flexible water outlet channels when connected to heating circuits should be provided with corrugated insulation to protect against abrasion.

Collector setting

Basic settings are made with the valves of the mixing unit. These operations use a hex key. When setting operating parameters, one should be guided by the scale readings with the device throughput values - on average, from 0 to 5 m 3 / h. This indicator indicates the flow rate of the coolant passing through the manifold valve. Also, the adjustment of the locking screw can be used to completely shut off hot water. When installing the collector of the warm floor, you can install a valve that automatically responds to pressure drops. In this configuration, the operating modes will be set by turning the regulator on an average pressure scale of 0.2-0.6 bar. After assembly, pressure testing and tuning of the collector, the system will be ready for use, but before the first start-up, the operation of the water supply line from the trunk group should also be tested.

The task of balancing the contours of the warm floor is to create on each branch the necessary flow of water with uniform heating. Relative to each other, the lines are balanced by valves or complete flow rate adjusters. Technically, balancing is implemented in the following way: the regulator or valve on each branch opens to a maximum, after which a circuit with a maximum flow deviation is selected compared to the normative. The regulator on this branch is covered up to the desired flow rate. Using the same algorithm, each collector circuit is configured.

Collector Group Operation

Collector control is implemented both in automatic mode with a programmable servo drive, and by manually setting the heating mode. At least a thermostat, directly connected to the collector, is included in the package of the warm floor. With it, the user sets the maintained temperature. Periodically, the system must be cleaned, balanced and checked for leaks. With your own hands, the collector for the warm floor can be diagnosed with crimping equipment, comparing the pressure gauge with the passport in conditions of a full pipeline loading. The quality of the connection is separately checked - in the nodes of connecting the supply and removal circuits of the coolant.

Conclusion

The function of the collector for the warm floor is to evenly distribute the flows of hot water through the laid pipeline. In an expanded configuration, this group performs the tasks of hydraulic balancing, shutting off flows, draining the coolant and removing air from the liquid. You can install the collector under the warm floor with improvised means, but the correct connection of its circuits to the water supply and drain lines will be of key importance. The energy efficiency of the equipment will be affected by the use of regulatory equipment. Particular attention is paid to the connection diagram of the adjustment valves, automatic air vents and drainage taps.