Construction industry companies offer a wide range of materials and components for the arrangement of interior building construction. Especially popular among consumers are plastic products that have high-quality characteristics and can become an adornment of any interior.

Plastic material has a wide scope. PVC-based products are lined with different surfaces of the premises: walls, ceilings, internal slopes of window openings, door and arched objects. If these planes are ennobled with plastic panels, then, accordingly, choosing a corner is not difficult. This is a PVC corner. If everything is more or less clear with the choice of finishing material, then fixing methods and compositions suitable for these purposes are not always known to consumers. How to glue a plastic corner to a plastic panel, we will consider in this article.

Geometric shapes and types of PVC corner

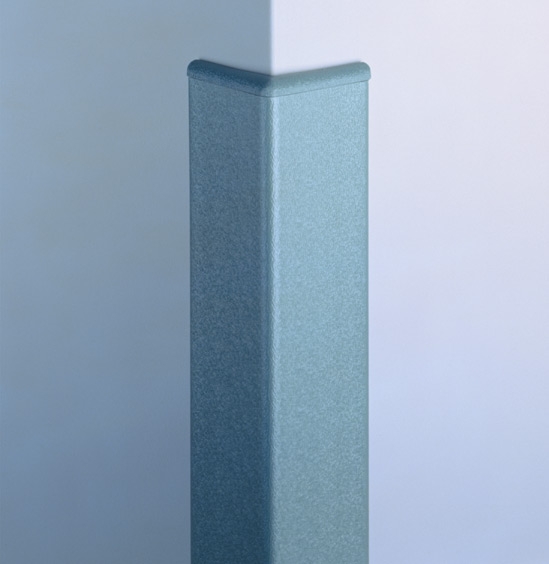

Plastic corner - a decorative element that provides a protective function to the angular edges of the panels, made on the basis of: polyvinyl chloride, stabilizer fillers and color pigment. It is the corners that are most susceptible to mechanical damage and pollution. They are equipped on the planes:

- external and internal corners;

- window, arched and doorways;

- in places where the wall adjoins the ceiling plane;

- window sills.

PVC corner panels have a palette of different colors and textures, are available in lengths of 2.5 m, have different widths, as well as double-sided coloring and different geometry shapes:

- equilateral corner panel;

- L-shaped arched profile;

- T-shaped profile.

To carry out the installation of corners to plastic panels, it is necessary to purchase an adhesive that has high-quality characteristics and is suitable for connecting the basics of plastic. And here a logical question arises: how to glue plastic corners with glue ? To answer it, it is worth considering the possible options that the modern market offers.

Characteristic Features of Adhesive Varieties

There are a large number of substances that differ in their basis and object of application. There are several options for gluing a plastic corner to a plastic panel. All formulations can be divided into the following types:

1. Polyurethane adhesive.

This type of glue is made on the basis of polymeric substances having the property of foaming and forming the hardness and reliability of adhesion of the connecting elements. It is available in two types, distinguished by the composition of the components: one-component and two-component. The advantages of a polyurethane substance are: excellent connection with various surfaces, adhesion between the elements of the connection, it has a high level of moisture resistance. Experts often recommend this composition as a suitable option for how to glue a plastic corner to a plastic panel.

2. Construction adhesive "liquid nails."

Manufacturers produce adhesive suspension in two variations, which differ in the ingredients of the structure: water-based and using organic solvents. These are acrylic and neoprene "liquid nails." Distinctive properties of the substance are quick setting and excellent adhesive performance.

3. Plastic liquid.

This substance is intended to connect elements only based on PVC. During installation work, the technology of applying liquid plastic should be strictly observed, since without the use of chemical reagents the possibility of removing excess applied substance is excluded. In this case, this is also a good option for gluing plastic corners to PVC panels.

4. Silicone glue.

This mounting agent is used to fix PVC profiles to ceramic cladding products, plastic panels, as well as wallpaper. To perform high-quality fixing of bonding elements, the most suitable option would be a silicone sealant with a high level of adhesion. Ideal for those who do not know how to stick a plastic corner in the bathroom.

Tool list

Uniform and accurate application of adhesives to fix the plastic corners is carried out using a mounting gun. You must also have additional tools that perform other functions:

- metal cutting tool;

- pencil and ruler or tape measure;

- masking tape;

- square metal;

- stationery knife.

Some rules for mounting the corner

Subject to certain installation rules of the plastic corner, taking into account the location of the object, the risks of deformation can be avoided, leading to the unattractiveness of its external appearance.

To determine the size of the profile width, it is necessary to measure the evenness of the angular face of the object. If the corner has a curved geometry, the optimal solution is a wide profile, and for even edges - a narrow product.

Particular attention should be paid to arranging the angular faces of the planes of door and window openings, since this is a rather complicated process that requires certain skills to form connecting lines.

Cutting of the finishing material is performed by a fine-toothed hacksaw. When deciding what is the best way to stick a plastic corner, the properties of the substance should be taken into account. It is important that its excess is easily removed from the panel. Colorless suspensions will be the most suitable option.

Ennoblement of PVC window and door corner edges

To perform the work, the following instructions should be followed:

- Measure the upper plane and mark the profile, taking into account the protrusions necessary for the design of the joints.

- Cut the profile with the necessary protrusions.

- Using the same method, prepare two side profile elements. The protrusions are marked only at their top.

- Mark on both profiles to form mating joints.

- Cut the protrusions facing the wall at an angle of 45 °.

- Apply glue to the inside of the element for horizontal slope.

- Press it to the base and fix it with tape.

- Install side profiles in the same way.

Arrangement of the arch structure with a plastic corner

Arch - an erected structural object located indoors and performing the function of a design element. Due to the location of the structure in areas with a high level of operation, the external corners of the object are subject to mechanical damage. To eliminate these risks, it is necessary to install decorative facing corners of PVC.

To do this, you must:

- determine the color scheme that matches the design of the space;

- acquire the required number of corner elements having a length of 3 m;

- corners with shelves having a width of different sizes should be prepared in order to avoid turning the profile in bent places.

The process of sticking PVC arch corner profile

In the process, it is recommended to adhere to the following implementation plan:

- arrangement of the base must be completed, the base must be in its pure form;

- prepare spacer structures in accordance with the size of the required height of the proposed installation;

- to try on a corner in a bendable shape on the plane of the arched opening;

- to mark with regard to the docking joints;

- place the glue mass on the wrong side of the corner;

- glue the profile into place corresponding to the midpoints of the dimensions of the arched opening and the plastic profile, establish a support, and also press it throughout the area;

- additionally fix the bending points with adhesive tape, imposing it on previously prepared cushioning materials (paper, film);

- leave to a full and high-quality grip;

- the second elements are glued in the same way;

- after full fastening, remove the adhesive tape and props.

How to glue a plastic corner: recommendations and advice of professionals

For high-quality performance of work, it will be appropriate to use some of the advice of professionals in the construction business:

- Error-free dimensioning on the plane of the corner will exclude the formation of gap spaces between the objects of bonding. An increase in the length of the profile within 1 mm will eliminate the risks of inaccuracies in the marking and will help the panel to take the correct location due to the elasticity of the product.

- Silicone glue should not be applied to minor cracks created during the adhesion of the connecting panels.

- When decorating doorways, it is necessary to correctly determine how to glue the plastic corner, in accordance with the basis of the surface.

- The installation of the arch corner is sometimes done using a building hair dryer that performs heating of the element. He must change the geometry of the corner from a straight line to a curved shape. The application of heating technology is limited to three attempts. Otherwise, the product is subject to deformation.

When doing the finishing work with your own hands, it’s not enough just to follow the installation instructions for the materials correctly, it is also important to choose the right way to glue the plastic corner to the plastic panel. The modern market provides a wide selection of formulations suitable for these purposes.