Fiber optic lines today provide the largest bandwidth of all existing communication channels. So, depending on the network equipment used, the data transfer rate can reach terabytes per second. Lines based on optical fiber are still mainly found in structured cabling systems for domestic use, but complete high-speed networks are gradually being transferred to this technology as the material gets cheaper.

Fiber optic cable structure

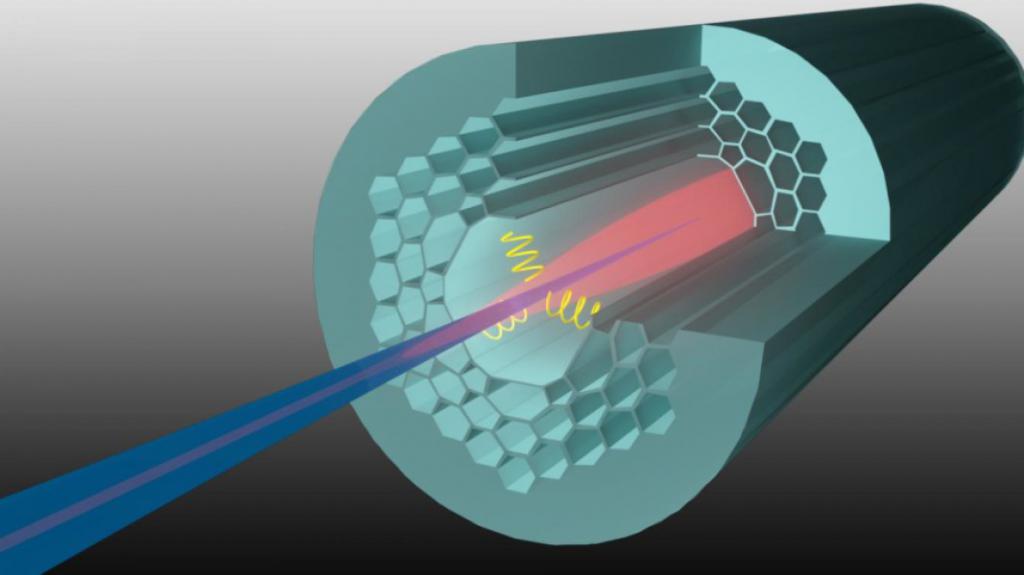

The fiber itself is formed by several layers, the core of which forms a core with an optical shell. The central part is made of a monolithic material - quartz glass, which provides a sufficient refractive index. Some modifications of the optical fiber also contain special additives that improve the quality of the main melt. For example, the same glass can be doped with oxides of phosphorus, fluorine, boron, etc. Moreover, it is not necessary to increase the refractive power. Sometimes high throughput is contrary to the properties of mechanical resistance, therefore, additives are introduced in order to reject the structure to the detriment of the quality of the connection.

If the core is made of quartz glass, then plastic is used in the working shell. Moreover, it is important not to confuse this layer with insulation as such. The cladding is also a functional part of the fiber, influencing the refraction of light and the optical qualities of the line as a whole. At the moment the light beam enters the fiber structure, internal reflection occurs, which moves along the core. This is the process of transmitting information.

As for the insulation itself, its function is performed by a special coating. As a rule, these are protective polymer layers capable of withstanding temperatures from -40 ° C to 60 ° C, as well as pressure up to 500 MPa. A double coating of an optical fiber with an outer sheath is also used. In this design, the outer layer not only physically protects the core from external influences, but it is also able to change the waveguide dispersion of the signal.

Varieties of fiber

The main classification involves the separation of fibers by mode light structure. In particular, the number of paths along which the radiation flux will pass depends on it. By this criterion, the following types of optical fibers are distinguished:

- Multimode. Large fibers that have a large diameter in the central part and can vary in the type of profile - stepped or gradient. If a thickness of the order of 50-60 microns determines a high transmission capacity and signal power, then the trajectory along which the light beams diverge depends on the profile. The direction of movement of the mods will ultimately determine the speed with which a particular beam arrives at the end of the fiber. Under the conditions of operation of the gradient profile, the time delays of the ray motion are almost leveled, and the modes are directed smoothly along wave-like spirals.

- Single-mode fibers. They are characterized by a small diameter in the core and, accordingly, provide movement in only one circuit. The diameter of a single-mode optical fiber is not more than 10 microns. However, the overall thickness of the cable structure may increase due to additional protective sheaths.

In addition to the number of mods, fiber classification by the presence of light transmission materials in the design and structure of the central functional part is used in principle.

Optical fiber characteristics

The ability of a fiber to transmit a signal is largely determined by its geometric and optical qualities. Among the characteristics of the geometric properties, non-circularity and non-concentricity can be distinguished. As for the first parameter, it is determined through the difference between the maximum and minimum thickness in one circuit, divided by the radius. Small optical fiber diameters of the order of 10-20 microns, as a rule, are characterized by small non-circularity coefficients. In turn, non-concentricity is determined by the distance from the centers of the sheath and the core of the fiber.

Of significant importance for the quality of signal transmission are the optical parameters of the material, which can be represented as follows:

- Attenuation. In other words, signal loss associated with a decrease in optical radiation power. The attenuation effect can be caused by various physical processes occurring in the structure of the optical fiber. The main factors of this influence include scattering and absorption.

- Numerical aperture. This characteristic is expressed by the sine of the largest angle of incidence of the light beam on the end of the optical fiber, at which full reflection is realized. According to this indicator, in addition to the signal transmission efficiency, it is possible to determine the number of modes propagating in one cable.

- Dispersion. This is the pulse repetition rate along the fiber, at which overlapping of some signals by others is also allowed. The result is the effect of intersymbol interference, causing possible errors in the processing of information.

Fiber Standards

To determine the general standards for the manufacture of fiber optic material, there are special standards. The G.657 marking, which was approved in 2006, can be attributed to the most up-to-date standard. This document, in particular, regulates the parameters of single-mode fiber cables that can be used in access networks. According to this standard, optical fibers should have a diameter of about 6-9 microns at a wavelength of 1310 nm. The IEC 60793 standard is also used, which describes methods and methods for testing fiber-optic materials, as well as their typification.

Fiber Connection Methods

To create multi-kilometer highways, the use of individual LEDs is inevitable. There are two different approaches to the splicing of fiber optic lines - by detachable and one-piece connection. In the first case, mechanical connectors are used. They require less effort in the connection process, but are expensive, require regular maintenance, and also adversely affect the quality of signal transmission. Therefore, one-piece or monolithic joints, implemented by gluing and welding techniques, are more often used.

The most common method of joining optical fibers is gluing. Special equipment is used for it, but the main work activities are carried out manually. So, before the operation, both ends of the lines are thoroughly cleaned, get rid of the protective coating and other insulators. At the time of connection, the ends of the fibers are placed in a special connector to fix the position. Next, epoxy glue is used to fill the internal cavities of the optical fibers, as well as free niches in the connector. A special connector is provided in the design of the connector for introducing the adhesive mass, through which the mixture is introduced through the dispenser. Then, drying and hardening operations follow. To do this, the design is placed in a special furnace operating at 100 ° C.

When the joint hardens, excess glue is removed and the surfaces of the connector are polished. The quality of the glued chip is checked using a high-precision microscope with a 200-fold increase. If necessary, the area is additionally processed with fine-grained abrasives until a smooth joint without pronounced seams is obtained.

Fiber optic welding

Special apparatuses are also involved in the work, the design of which includes a power supply unit, a mechanical part holding the workpiece, an electrical filling, a hardware part, and a heat shrink oven with working desoldering bodies. The process looks like this:

- Fiber cutting. The protective shells, insulation and casings are completely removed until a structure of 8-16 fibers is opened, which are then cleaned.

- A sleeve with two heat shrink tubes and a rod is put on the fibers.

- A special cleavage is performed with a precision cleaver so that the surface of the thread from the side of the cavity is perpendicular to the axis of the contour.

- The fibers are stacked in the clamping mechanism of the apparatus.

- Alignment is carefully carried out, that is, fitting the parts to be welded to each other.

- An electric arc is ignited.

- Direct welding of the optical fiber is carried out with a slow movement to the heat chamber, where the material will be shrunk.

- Welded fibers must be laid in a special form to restore the temperature regime without damaging the structure.

This technology provides high-quality connection with negligible loss in light transmission coefficient. The construction of high-speed fiber optic routes is usually performed in this way. In industrial conditions, laser welding of increased accuracy is also used today, which performs almost perfect melting of the ends of the fibers, practically leaving no traces of adhesion.

Fiber optic lines

Such cables are mainly used for organizing signal transmission networks around and inside objects. External communication lines on this material are built in very rare cases due to the high cost. Nevertheless, for domestic use, this technology is the best solution as an affordable means of high-speed data transfer on a digital platform. Moreover, in comparison with traditional networks, the laying of optical fiber on the way to the subscriber does not require connection to active equipment - the line stretches directly to the place of operation. In part, and thanks to this feature, a high throughput of the information path is achieved. Of course, the channel itself can be divided into separate sections that are serviced by splitters, but they practically do not affect the quality of data transfer. Already at the place of operation, an Ethernet interface, Wi-Fi modules, a router or other connection devices can be used as a signal converter. All the possibilities for branching the network in the room are also saved.

Technology advantages

Optical fibers have a lot of advantages due to the optical method of data transmission, as well as the specific physical characteristics of the material of cable manufacture. It’s worth starting with the already mentioned speed, which can reach 1 Tbit / s, and this is far from the limit even today. The nature of the use of lines is universal, which gives one more plus. Several optical services can be provided to a subscriber via one optical cable, including television, Internet, telephone, etc. Since there is no electric voltage on the line, it is not afraid of moisture. But, of course, this does not mean that the fiber is completely protected from external threats. To the main listed advantages of optical fibers, there are several more important advantages:

- Compact and light weight.

- High noise immunity.

- Cable durability.

- The flexibility of the material.

- Unauthorized access to the transmitted information by induction reading, insertion and other methods of invading the data line is excluded.

Cons of technology

The fiber optic line has a number of significant drawbacks associated with the structural device and also with the technical qualities of the material itself. The disadvantages of the cable include the following:

- Sensitivity to bending. Quartz glass as such with significant bends can break, but even if this does not happen, there will be a deterioration in the signal. Accordingly, there are limitations when installing optical fiber in tight laying conditions.

- High cost of cable. Manufacturing technology, processing and external coating corresponds to the price of twisted pair production of the highest fifth category.

- The difficulty of repairing and repairing at breaks. Without a special tool, repair work is impossible. In this case, specialists sometimes have to replace entire sections, since certain categories of damage entail negative consequences of deformation throughout the entire near structure of the fiber.

Conclusion

Fiber-optic technologies do not stand still and almost every year demonstrate improvements in certain technical and operational qualities. One of the latest developments in this segment can be called bio-soluble light fibers, which can monitor the state of the material structure using sensors.

At the same time, the scope of application of the optical cable is expanding, the advantages of which are highly appreciated by the developers of burglar alarms, video surveillance systems and telemetry. While wireless data transmission modules are being actively introduced into security tools, the principles of creating a confidential secure network based on high-speed optical lines are being mastered in parallel. This concept outperforms attractive wireless networks due to its stable operation, elimination of interference and wide possibilities of creating closed subnets. If before the builders of cable infrastructure on the same twisted pair used these advantages, today they can be provided even more with fiber optics. Of course, making corrections to the weaknesses of this material.