In recent years, more and more motorists have chosen to use diesel cars. Previously, such motors were installed only on commercial vehicles. However, now they are also actively used in passenger cars, especially in Europe. Surely each of us has heard of a system such as Common Rail. What is it and how it is arranged, we will consider in our article.

Characteristic

"Common Rail" is a fuel injection system for diesel engine. Its principle of operation is based on the supply of fuel to the nozzles from the total pressure of the ramp.

The system was developed by German specialists at Bosch. Common Rail Bosch is widely used on cars such as Volvo, Mercedes, BMW and others.

What is the feature?

The main distinguishing feature of the system is the ability to deliver the right power with minimal fuel consumption. Also fuel Common Rail is able to reduce the level of toxicity of exhaust gases. Automobile reviews say that a car with such an injection system works much quieter (there is no such characteristic "roar" as on old diesels). "Common Rail" has a wide range of fuel pressure control and injection start points.

Device

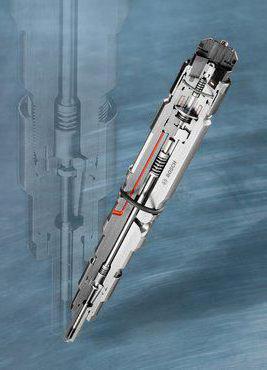

By design, the Common Rail system is a high pressure circuit. When the engine is running, direct fuel injection is performed (that is, fuel enters directly into the cylinder chamber). There are several elements that are associated with the operation of the Common Rail system. What are these components? First of all, this is a high pressure fuel pump. The metering valve and pressure regulator are also used in the work.

In addition, the design has a fuel rail and nozzles. Common Rail is a fairly complex system, and to understand its principle of operation, we consider the features of each component.

Pump

So, fuel pump. This mechanism serves to create high fluid pressure . The level depends on engine load and crankshaft speed. As you know, on diesel engines, the speed is not regulated by opening the throttle, but rather by the portion of the fuel supplied. The fuel injection pump is responsible for this. The device is quite complex, so this element is the most expensive component in a diesel car (over, with the exception of the main units, such as ICE and gearbox).

Common Rail Regulator and Valve

What is this element? The valve is used to adjust the amount of fuel that is supplied to the pump.

Structurally, the element is combined with a high-pressure fuel pump. There is also a fuel pressure regulator. It is installed in the fuel rail and controls the operation of the engine depending on its load.

Ramp

This node performs several functions at once. This is the accumulation of fuel under high pressure, mitigating pressure fluctuations and the distribution of fuel in the nozzles. It is part of the intake system.

Nozzles

It is worth noting that those are installed both on gasoline (injector) and diesel engines. However, their main difference is the pressure that they create. In our case, the “Common Rail” nozzle also controls the amount of fuel that is supplied directly to the cylinder. The element is connected directly to the ramp. At the moment, two types of nozzles are used:

- Piezo nozzles ("Bosch").

- Electro-hydraulic (the main manufacturer is Delphi).

In the latter case, the fuel supply is due to the operation of the electromagnetic valve.

In piezo nozzles, special crystals are responsible for this. The speed of these elements is an order of magnitude higher, so they are more common. However, repair of Common Rail (nozzles) is not possible to do it yourself because of the complexity of the design and the exact settings. Therefore, all system maintenance work is carried out only at specialized service stations. This is the main drawback of such cars.

How does it work?

The operation of the injection system is controlled by a diesel control system. The latter includes actuators, sensors and ECUs. All parameters are taken into account - the position of the gas pedal, the temperature of the coolant, the amount of air supplied and even the composition of the exhaust gases (lambda probe). As for the actuators, they are the above nozzles, ramp, high pressure fuel pump, regulator and valves.

So how does this system work? Based on the signals that control sensors perceive, the system generates the right amount of fuel. It is fed through a metering valve. The fuel enters the pump, and then goes to the ramp under pressure. The desired pressure in it is held by a special regulator. At a certain moment, the signal from the computer enters the injectors, and they open the channels for a certain period of time. Depending on the engine operating mode, the amount of fuel and pressure can be automatically changed by the system based on data from the oxygen sensor. However, the take-off should be small. Significant deviations indicate a malfunction with the Common Rail system.

Common Rail Injection Types

What it is? There are several types of fuel injection in the system:

- Preliminary.

- Main.

- Additional.

The first is done in front of the main one in order to increase the pressure and temperature in the combustion chamber. Thus, accelerated self-ignition of the main charge and a reduction in the noise of the engine are carried out. Pre-injection may be different, depending on the mode of operation of the engine. So, at idle, it is done twice. With increasing load - once. At full load, pre-injection is not performed.

The purpose of the main injection is to provide direct engine operation. It is not subdivided into subtypes. An additional injection is used to reduce exhaust emissions. So, information is sent to the computer from the oxygen sensor, after which another portion of fuel is supplied. Harmful substances are burned in a catalytic converter (also called a

particulate filter).Generations of Common Rail

It is worth noting that the first generation of the system appeared in 1999. She gave out a pressure of 145 MPa. Two years later, the next generation of the system appeared (160 MPa). Common Rail 3 was developed in 2005. At the moment, cars are equipped with the fourth-generation Common Rail system. Nozzles operate at a pressure of 220 MPa. Why is such attention given to pressure? The higher this indicator, the more fuel is injected into the cylinder. Accordingly, for a certain period of time more power is realized, and engine efficiency increases.

Conclusion

So, we found out what constitutes a direct injection system, how it works and how it works. It is worth noting that the "Common Rail" is used on most diesel cars, in particular, European production. The system, despite its complexity, has great potential.