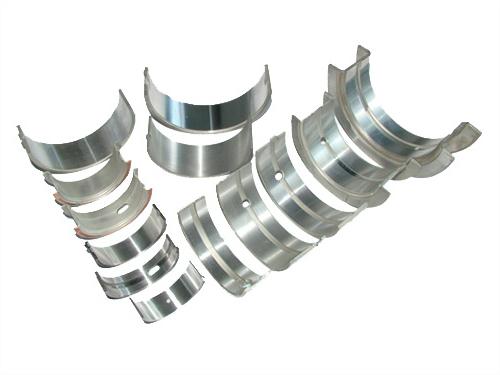

In the life of every car owner, sooner or later, a moment comes when his iron horse has exhausted all its resources and can no longer serve faithfully. Sometimes such troubles do without any serious procedures, but it also happens that boring the engine is the only way to bring it back to life. It happens when only the crankshaft journals are ground. Such measures are taken in the event of a drop in pressure in the lubrication system, as well as in the case of play in the lower connecting rod head. Still have to replace the liners.

But this is the most harmless case of engine repair using "surgical intervention". It happens that the engine cylinders wear out, lose their rounded shape and become oval. The longer axis has a direction of rotation of the crankshaft and the opposite to it, since it is in this direction that the greatest loads on the metal are tested, which means that it is here that it wears the most.

Boring cylinder blocks is an incorrect, incorrect expression, since the block itself is not bored. This operation is carried out exclusively with cylinders. All of them have nominal and repair dimensions. If the wear is too large, a bore is carried out to the nearest repair size. If the ovality is too large, then two or even three sizes are removed immediately, which, of course, implies the replacement of the pistons. Boring of blocks is carried out by experienced specialists on precision equipment, since the values here are comparable to 0.001 millimeters. It must be assumed that a simple person from the street will not be able to carry out such an operation. However, even a professional without the proper equipment is also not capable of this.

Another case in which an engine bore may be required is a deliberate increase in displacement, namely tuning. Of course, 2.5 cannot be made from a 2-liter engine, but everything is made up of little things. Engine boring is a pretty effective, but not magical way. Here you need even more accurate equipment, as well as the master gold hands.

But sometimes it’s not so complicated and scary. It is possible that the pistons rings did not wear out. Naturally, the former also cannot avoid it, but repairs can be limited to the latter, which, of course, is much cheaper.

In order to find out what needs to be repaired, measurements should be taken, which are called troubleshooting. To determine the wear of the rings, a probe is used, as well as a micrometer or vernier caliper. They measure the thickness of the ring and the distance in the lock, that is, at the junction of its ends. This distance is called the thermal gap and is different for different engines.

The ovality of the cylinders is determined by the caliper, which measures the diameter of the cylinder at six points: at three — along the length and perpendicular to the measurement axis. Troubleshooting is the only sure way to determine if an engine bore is required or not. But here, too, there are small pitfalls that can cause a lot of trouble and problems. One of them is the inaccuracy of the measuring tool, so you need to select it carefully. If you do not carefully select the required, then this is fraught with different sizes in the cylinders after boring, which means that the engine will fail.