The advantages of installing metal-plastic windows are not only in operational characteristics, but also in ease of installation. The process is quite simple, facilitated by the fact that there are many devices for fasteners and additional elements. Moreover, all these devices and elements are present in the configuration from the factory. And if you are friends with the tool, then you can do it yourself technology-based installation of plastic windows. Of course, you need patience and accuracy, as well as at least one assistant. In this case, you will make the installation of windows as high quality and absolutely free.

Carrying out preliminary measurements and calculations

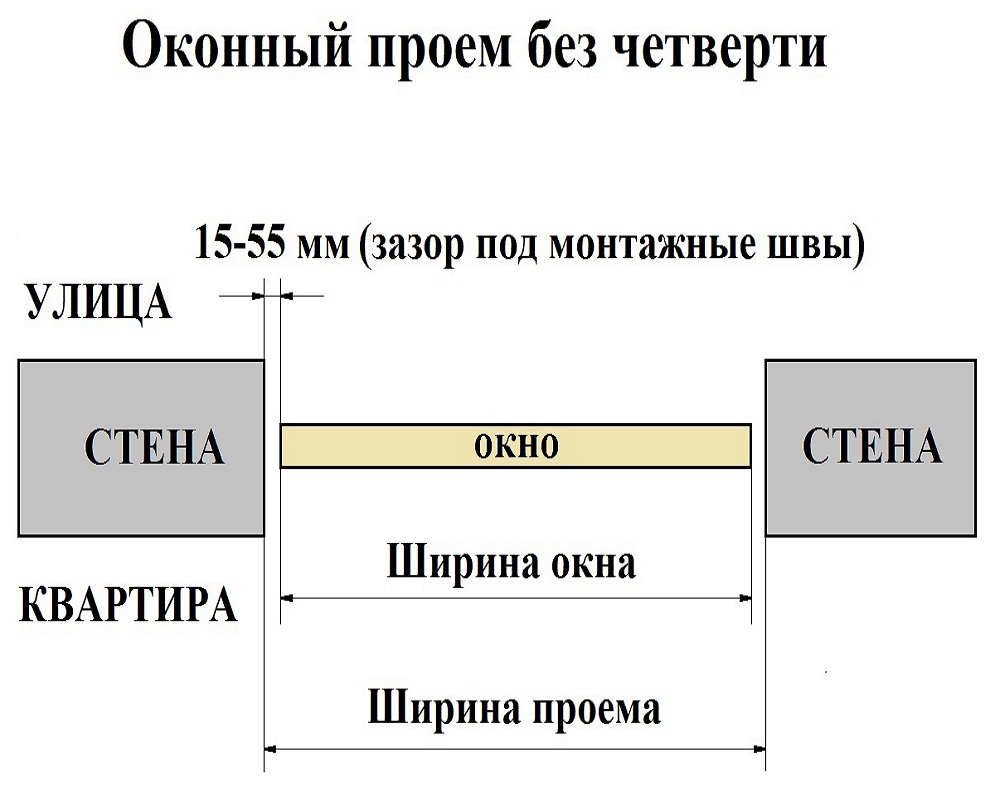

Before running to the store and buying windows, it is necessary to measure the openings. Be sure to consider if there is a quarter on it. With a quarter openings are commonly used in foam concrete buildings. They are able to significantly reduce heat loss. If the opening does not have a quarter, then you will need to purchase windows, the length of which will be approximately 5 cm less. The width should be less than 3 cm. It is necessary to leave a gap of one and a half centimeter around the entire perimeter, so that it can subsequently be filled with polyurethane foam. By installing plastic windows in the apartment, you can achieve significant savings on heating.

3.5 cm below must be left in order to install the windowsill. If you focus on GOST, then you need to leave exactly 2 cm along the entire perimeter. In order to equip an opening with a quarter, you need to take a measurement in the narrowest place. The length of the window should be the same as that of the opening, and the width should be more than 3 cm.

Window sills and ebbs

As a rule, windows are not located in the center of the opening, but at a distance of 1/3 of the length, closer to the outside. But if you wish, you can measure and install plastic windows with your own hands, moving it in any direction. But this must be taken into account at the time of ordering the window sill and outdoor tide. After all, the dimensions of these elements depend on how the window will be located relative to the opening. When calculating the width of the window sill, it is necessary to take into account the position of the battery.

The window sill should overlap the radiator by about half, no more. It is also necessary to add about 2 cm to bring the window sill under the base of the metal-plastic window. It is necessary to leave a margin of at least 8 cm in length, but it is better if you leave 15 cm. Only in this case you can cut the window sill beautifully. And never give up the plugs that are installed on the ebbs and window sills. They are inexpensive, but it will significantly improve the appearance.

Frame mounting methods

The technology of installing metal-plastic windows with your own hands in no way depends on how many cameras are inside the profile. Also, it does not depend on how many cameras are directly in the double-glazed windows. Technology directly depends on what material the house is built of, as well as on the size of the window. Based on these data, it is necessary to choose the most optimal way to implement fasteners.

There are only a few:

- By means of mounting anchors or dowels, which are inserted into the walls through holes pre-drilled in the profile. Next, we will consider the technology of installing plastic windows with your own hands in this way.

- With the help of special gear plates, they must be pressed into the profile. It should be noted that they are not inserted directly into the wall, but are put into place and secured with screws.

Expert opinion

It is worth following expert advice. And many advise anchor plates to position openings openly. After completion of installation work and the end of foaming, it is necessary to establish slopes. Anchor plates will be hidden under them. All space that is located between the planes of the slope and the opening must be filled with foam. To reduce the consumption of foam, you need to make a small depression under the plate.

And now let's look in more detail both options for the implementation of fasteners.

Features of frame fasteners

Using anchors is the most reliable method, many use it when installing metal-plastic windows. But most often it is used in the installation of heavy and large window structures. The fastening is through, so the window is well resistant to various loads of shock type. They arise, for example, during the operation of windows with sashes that open in different directions. In addition, the anchors pass through the frame, which allows you to most accurately adjust horizontally and vertically the entire installed structure.

But if you have a small window and the windows are deaf, it is easiest to use anchor plates. They will not be able to spoil the appearance of the structure, since subsequently they will hide under the slopes. If you install anchor plates in a brick or concrete opening, it is best to make small recesses so as not to apply an extra layer to align the internal slope.

What do the professionals do?

Very often installers combine these two methods. Anchors are buried in the walls through the side of the frame and the base of the metal-plastic window. The upper part is fixed with anchor plates. And in the event that plastic windows are installed in a wooden house with their own hands, anchor plates are not used, since they are very loose. It is best to use wood screws covered with a layer of zinc. This will protect the metal from corrosion.

Features of installing windows in wooden houses

Very often, the installation process depends on the building material from which the house is made. If the walls are of hollow or solid brick, foam concrete, the differences in installation are small. And they will consist only in the size of the depth of the anchors. But if the openings in wooden buildings, then many nuances must be taken into account.

And more specifically, when installing plastic windows in a wooden house with your own hands, you need to consider the following nuances:

- It is recommended to install metal-plastic windows in a wooden structure only after shrinkage occurs. This is about a year after the construction is completed. It should be noted that the shortest shrinkage period for buildings made of glued beams.

- Do not mount windows directly in the opening. First you need to install a box of wood, it will protect the entire window structure from deformation. No damage, rot or defects should be present on the window unit. Before you begin, you need to thoroughly treat all surfaces with antiseptic agents.

- Slight shrinkage after installing windows and final finishing will still occur. Therefore, it is necessary to leave a small gap between the top of the opening and the box, 3-7 cm is enough. This value directly depends on which building materials are used, as well as on humidity. After this gap must be filled with insulation and closed with platbands from 2 sides.

A little more about wooden houses

Completely different rules for installing plastic windows in brick houses, this will be discussed later. Now let's talk about wooden buildings. You will not find exact recommendations about what materials should be used for the manufacture of window sills or ebbs. As a rule, low tides are installed those that come with the design of the window. But the windowsill can be made of polymers or wood.

Please note that this profile can rest directly on the window sill made of wood. In other words, you can install a window sill before the installation of windows begins.

There is one small point that is not specified in the standards. But it is recommended by all experienced builders. If the wood is able to pass evaporation, then the mounting foam will lose its technical qualities. And so that it does not get wet, it is necessary to process the entire block along the line of applying foam with a plastic foil tape. The same requirements for installing plastic windows on the balcony with your own hands. All parts of the foam that protrude must be treated with a waterproofing compound.

Installation Standards for Plastic Windows

A distinctive feature of do-it-yourself plastic window installation technology is that foam is used. It gives rigidity to the connection of the opening and frame. The layer that results from the hardening of the foam performs the function of not only an insulator, but also a fastener. In order for the foam to retain all its technical characteristics, it is necessary to surround it with a layer of insulation. To do this, glue insulating strips on both sides. It is imperative that a material with a waterproofing effect is used from the outside. And from the outside, the coating should have vapor barrier properties.

When it is best to install plastic windows, it's up to you. Some installers advise installing windows in the cold in order to immediately reveal all the flaws. But it is necessary at the same time to choose the right mounting foam so that it hardens in cold weather. It is recommended to use professional compounds. And in order to work conveniently at low temperatures, you have to purchase a special nozzle.

It is necessary to fill the openings with foam from the bottom, making rotary-circular upward movements. In order to avoid overspending, it is necessary to blow out the foam in several steps, filling the segments no more than 30 cm. In order to shift the dew point, foaming should be performed with an uneven density. So, the part of the layer that is closer to the street should have a density less than the inside. But gaps and voids are not allowed. Be sure to install the tides on plastic windows, you can do it yourself quickly enough.

How to prepare a window opening

The most important thing is to clean everything from debris, dust, paint, as well as other objects. In the event that you will install a metal-plastic window in an old wooden box, you need to remove the top layer of wood. Only in this case, the foam will seize the upper layer. All the gaps between the opening and the frame must be filled only with foam, but only if the distance is not more than 4 cm. If the gaps are much larger, they can be filled with cheap materials like drywall, brick, polystyrene foam, timber.

How to prepare a window

Now the fun begins. You need to perform the following manipulations in order to prepare the window for installation:

- Free the frame from the sash, pull out the pin, which is installed in the upper hinge. It must be picked up as carefully as possible below with pliers and a screwdriver. After this, slightly raising, it is necessary to remove the sash from the hinge located below. If the windows are large, then be sure to take out these double-glazed windows. Before this, remove the longitudinal and transverse glazing beads. In order to remove glazing beads, it is necessary to carefully fit into the gap and displace with the thick side of the knife or with a spatula. Be careful not to damage the glass. If the metal-plastic window has small dimensions, then it can be installed using plates and without removing the double-glazed windows. If there is such a possibility, then do not violate the integrity of the entire structure.

- Then you need to lean the sash or double-glazed window against the wall, put some soft material or cardboard under it. Flat laying is strictly prohibited. It is also impossible to install with a warp, since a small pebble that has fallen under the base can cause cracking.

- Remove the film from the outside of the frame. If at this stage you do not remove it, then subsequently it will be much more difficult to do and it will be necessary to use an industrial hair dryer.

Marking places for fasteners

Regardless of which mount you choose, you need to mark the places for installation. Many builders recommend a step of about 40 cm or less. GOST allows increments of up to 70 cm. In the event that you plan to use mounting plates, you need to fix them in advance on the frame using self-tapping screws. And if you are going to use anchor bolts or self-tapping screws, then you need to make holes using a drill from the outside of the frame.

Installation process

Many people ask: at what temperature do plastic windows install? It is better to do this during the cold weather, because all the "jambs" can be seen immediately after installation. And now about how the technology for installing plastic windows looks, in more detail:

- First you need to install a frame in the opening, around the entire perimeter you need to put corners of plastic or small blocks to withstand the necessary clearance. Carefully move these wedges and expose the frame horizontally and vertically. Ensure that all side clearances are the same. All spacers are recommended to be located near the fastener point with an anchor or self-tapping screw. They will protect the entire structure from deformation.

- Differences can be observed when installing plastic windows on different houses. If the doorway is in a wooden house, then just screw the self-tapping screw into the holes in the frame. If the walls are made of brick or foam concrete, then it is necessary to mark the points through the holes in the frame. Then remove the frame and drill holes with a hammer or hammer drill. Install anchors in it.

- After checking the vertical and horizontal position, you can finally fix the profile. But it is not recommended to tighten strongly, otherwise the frame will stand out. As soon as the self-tapping screw head is on a par with the frame, you can complete the tightening. Some installers recommend not reaching about 1 mm.

- All removed items must be installed in the reverse order. After that, the operability of the entire structure is checked.

- Fill all gaps with foam. On the outside and inside, the seams must be closed with protective tapes.

- As well as foam, you need to fill the gap that is under the sump. Install it in such a way that the slope is from the window, fasteners are carried out using screws to this profile.

- And after the foam hardens, you can install the windowsill. Plastic should start about a couple of centimeters under the bottom profile. But if you need to make a slight deviation from the design of the window, the whole space that is under the windowsill can be foamed.

- All slopes are recommended to be done directly on the day when the installation is carried out.

After completing all installation work, you must withstand at least 16 hours. Do not use windows so that everyone does not break. Such a step-by-step instruction on installing plastic windows with your own hands will come in handy if you decide to perform all the work without the involvement of specialists. But it is recommended that before starting work, familiarize yourself with the recommendations of experienced craftsmen. They will not be superfluous.