In modern construction, of course, the materials used are modernized. Various mixes, plasters, composites. Particular attention is paid to the materials used for the construction of walls and ceilings of buildings. Traditional bricks are being replaced by lightweight concrete. What are they? What are the technical characteristics? Will winter residents of future houses be allowed to freeze in winter? In the summer? Will they not let me languish from the heat? Let's try to figure it out.

For the first time, a mixture of cement, large porous fillers, sand and water was tested at the end of the nineteenth century. But they began to apply it in construction much later. Already in the twentieth century. Lightweight concrete appeared decades later. Its difference from previous species is specific gravity. Speaking in technical language, it should be no more than one thousand eight hundred kilograms per cubic meter. Only then is concrete considered light. This technical property can be achieved by the presence of expanded clay or slag in the composition. Accordingly, such types are called: expanded clay concrete or slag concrete. But here also can be attributed excellent in production, but with similar qualities, polymer concrete, foam concrete, polystyrene concrete, aerated concrete. Why are they produced and where are they used? Most often, lightweight concrete is a component of floor slabs for basements, ground floors of buildings, attics. This is explained by the fact that such partitions are heat-intensive and, accordingly, save energy costs.

Lightweight concrete differs from the usual heavy ones by its high porous qualities, low weight, heat saving. These types of building materials are indispensable in the construction of high-rise buildings. Lightweight concrete on porous aggregates, of course, inferior in strength properties. The issue is easily solved. They are improved by introducing reinforcement into the structure.

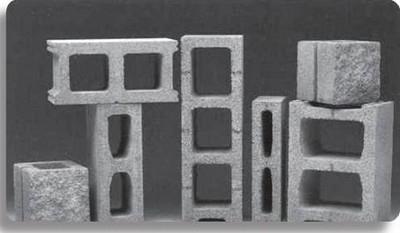

Lightweight concrete has been widely used recently in private construction. This is natural, due to the cost of such material. According to their tasks in such works, lightweight concrete is divided into two types. The first is material for load-bearing walls with porous fillers, with a specific gravity of over one thousand four hundred kilograms per cubic meter. Such concrete is called "constructive". Another type and, accordingly, the brand is heat-insulating. The name speaks for itself. Used in the construction of non-bearing walls. The weight of such material does not exceed five hundred kilograms per cubic meter.

Walls of buildings are not the only application for lightweight concrete. They have proven themselves in the filling of decorative forms. This was facilitated by high plastic qualities. And its light weight made concrete competitive in the production of decorative products with heavy gypsum. Colons, pilasters, rustics, cornices from the hands of masters come out surprisingly elegant and original.

Lightweight concrete, whose GOST meets all standards, is an excellent solution for private construction, the manufacture of fences, fences and other structures involving designer intervention.