All children from early childhood dream of becoming someone. Some want to be pilots, others - astronauts, others - television presenters. However, in addition to such grandiose plans for the future, there are also less ambitious aspirations, for example, helping parents at home, participating in school activities, and completing creative tasks. The latter, as a rule, include needlework: girls learn to sew and knit, and the boys begin to work with various tools and learn the basics of repair and manufacturing of new products. When the first steps in this matter are assimilated, the boys want to start more complex tasks, therefore, when they find themselves in the school office of technology, they immediately light up the desire to stand at some machine and use it to make something. As a rule, a technology teacher teaches you how to work with a drilling machine, then with a turning machine. These are already more serious devices that deserve special attention.

Types of Lathes

A bit of theory about lathes. It will be useful to know about their main types, since the general idea of these devices can broaden their horizons, increase the amount of knowledge in this area, and this, in turn, will allow more bold operations during work (this is how it works: the more we know, the we feel more confident).

- Screw cutting machine . Designed for the processing of metals (ferrous or non-ferrous), the manufacture of them cones and various types of carvings.

- Revolving machine . It also has the goal of manufacturing metal parts. It works with calibrated rods, which are long metal sticks that can be processed.

- Carousel . It helps when you need to do work on large workpieces.

- Multi-cutting machine . It is very good to use for mass or mass production of parts, mechanisms, devices. Provide the ability to process the workpiece at once with several cutters.

- Machine tools with manual, foot and electric drive . The first two move the workpiece by hand or foot, respectively. Such machines are well suited where there is no power supply. In the latter, the product is rotated by an engine operating by supplying current to it.

There is also a classification of machines according to the material with which they can work. Depending on this, these devices are divided into lathes for metal and wood. Today we’ll talk about the latter form, because in practice at school and in everyday life it is most often used.

Wood lathe: device and purpose

A wood lathe is a device that is powered by electricity and designed to process wooden workpieces in the form of a body of revolution. It allows you to actually sharpen the material, to carry out its cutting, as well as cleaning with sandpaper.

These operations are performed using a special tool - a chisel. This is such a hand tool, which consists of a wooden or plastic handle with a metal sharp tip, which can have different shapes. Using a chisel blade, unnecessary material is removed from the workpiece, and due to this, a product of the desired type with the correct design is obtained.

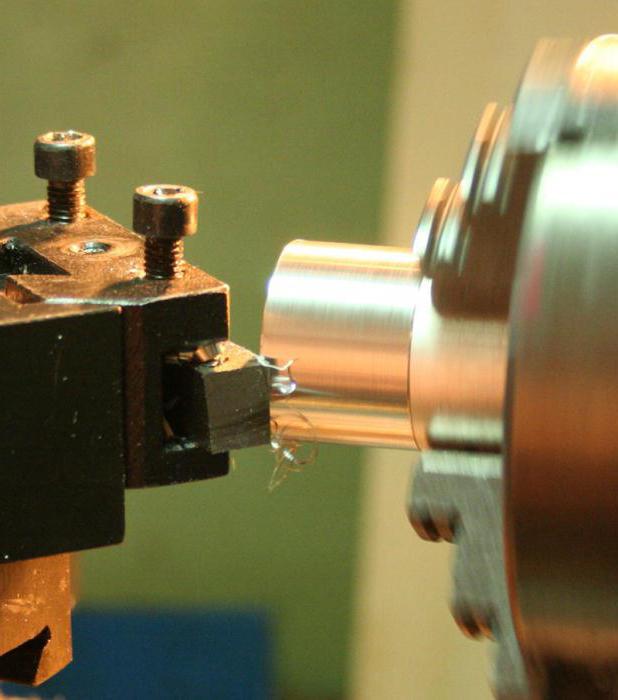

The process of processing the product itself is carried out by combining two types of movement: rotational (comes from the workpiece itself using a lathe) and translational (comes from the chisel, adjusted by the employee).

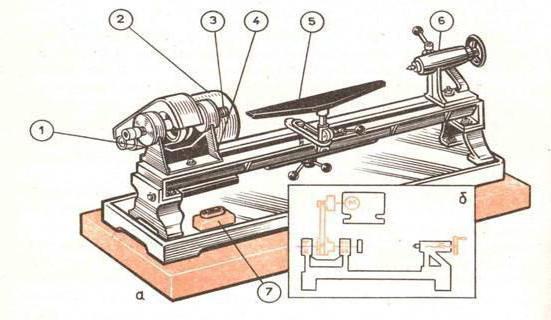

Wood lathe device STD 120

It's time to learn about the internal and external components of the device we are considering. It should be noted that the STD 120 model is the most common and is widely used in schools. Therefore, it will be useful to know for both a simple citizen and an ordinary student the device of a wood lathe. A description with the corresponding diagram is shown below:

- Belt drive . Her task becomes the transfer of rotational motion from the electric motor to the spindle.

- Electric motor Its purpose is that it should generate a rotational motion with the help of electric current, which is then transmitted to the workpiece by means of a belt drive and a spindle.

- Spindle This is one of the parts of a wood lathe that acts as the left fastener for the workpiece. The spindle also closes the transmission of rotational motion from the electric motor to the workpiece.

- Front headstock . It is designed to support the belt drive mechanism and spindle.

- The hand of the . This part of the lathe serves as a support for the chisel during processing of the product.

- Tailstock . This part is necessary for fixing workpieces of different lengths, and also acts as the right fastener for the product. It has a movable mechanism, thanks to which it can move along the bottom of the machine to the left and right side. This allows the worker to insert into the machine for processing short, medium or long workpieces.

- Keypad Here are the buttons on and off the lathe.

The question arises: "Which wood lathe device is the most important?" In principle, all the components are necessary for proper and safe operation, therefore, a definite answer to this question cannot be given.

Machine STD 120M

The wood lathe device STD 120M will be described in this section. Its name is almost the same as the previous one, but in fact it is not. Please pay attention to the end: there is the name of another model of a wood lathe. It is a modernized version (hence the letter "M" after 120) of a wood lathe STD 120. It has several features:

- The presence of protective mechanisms against flying chips during work with the workpiece, represented by special transparent plastic panels.

- The ability to automatically clean the machine using the built-in cleaning mechanisms.

- Several spindle nozzle options that can be changed. This greatly simplifies the compatibility of workpieces with the machine.

- Improved belt drive mechanism, providing a higher rotation speed of the workpiece.

- Convenient location of the keypad.

Safety rules when working with a wood lathe

This device can become life-threatening and dangerous if not properly prepared. However, the work becomes absolutely safe and comfortable while observing safety precautions.

Preparation:

- The worker must be dressed in special clothes, have safety glasses and gloves.

- It is necessary that the workpiece has a primary manual processing.

- There should be no unnecessary items on the machine.

- Before work, you need to check the condition of all the components of the lathe, especially for belt transmission, spindle and keypad.

- Check the operation of the machine. To do this, he can be allowed to work a little idle.

- The handle should be installed at a distance of 2 to 3 cm from the workpiece.

In progress.

- In no case can you pull your hands to the rotating workpiece, strongly tilt your head to it, move away from the working machine.

- The chisel should be brought in smoothly, avoiding sudden movements.

- From time to time, you need to turn off the machine to safely move the handcuff to the workpiece, reducing the increasing distance between them.

After finishing work.

- It is necessary to turn off the machine, remove the finished product from it.

- Clean the chips using a special brush or other cleaning tools.

- Return used tools to their places.

Home use

To work with a lathe on a tree at home, you must first prepare a special room for it. If this is not possible, then a small corner with an area of at least 4 m 2 is also suitable. The area around the machine must be free from foreign objects. Before work, you must definitely warn your home so that no one interferes with each other.

Use in the office

Work should only be carried out under the guidance of a technology teacher or experienced class teacher. Further terms of use remain the same. The only thing that should be remembered is the need to coordinate their actions with the teacher. Often students begin to self-will, because of which there are conflicts between them and the teacher, which is not the best way affects their performance.

School Lathes

Since the beginning of the article was devoted to the creative development of boys, one cannot but emphasize that such an excellent opportunity appears in the technology office. Here you can cut a saw, and cut something with a jigsaw. But, of course, the most interesting part begins with the study of the device of a lathe in wood. Grade 6 - this is the very time when the student begins to take his first steps in this field of knowledge. He will learn how to make products first with the help of a teacher, and then himself. Then the student will only begin to expand his skills. He may have the opportunity to work on a more advanced model STD 120M. But for the training to be as effective as possible, and the practice is safe, of course, first you will need to get to know the modification of the STD 120 in more detail, again examining the device of the wood lathe. Grade 7 will provide such an opportunity.

Some tips

Experienced people recommend first of all to show patience and carefully prepare for work at the machine. If in a hurry, you can overlook some of the safety precautions. Also, many are advised to specially allocate time for work, because it often takes a considerable number of hours.

In conclusion

Wood lathes are indispensable tools in the manufacture of practically useful or decorative products. Having widespread use in past centuries, these devices have not lost their relevance in our days.