The beer business has flourished for many centuries, and there are several million beer lovers in the world. But among them there is hardly any one who prefers to drink this drink warm. Experts believe that the temperature of beer poured into the glass should be within +4 ° C + 6 ° C, and at the outlet of the tank it should be about +2 ° C. Beer cooler - a device designed to maintain an acceptable temperature in draft beer at which the exclusive taste of the drink is fully disclosed. It is a mandatory and very important element of beer equipment, whether it is installed in a stationary room or at a street trading point. There are several types of coolers and many models on sale. They differ in design, price, and most importantly, by the principle of work. Which one to choose, so as not to pay extra money, and not ruin the business, our article says.

Classification

Before everyone who decided to organize a beer business, a question will surely arise which beer cooler to purchase. Despite the wide selection of brands and models of these units, at the installation site they can be divided into two types:

1. Superstructure.

2. Trimmer.

There are also devices called kegerators, but they are mainly used for cooling a small amount (up to 2 kegs) of expensive and elite beers. Cooling in them reaches the design temperature in a few hours.

The second classification is based on the principle of operation. There are also only two types of coolers here:

- flowing (popularly called wet);

- dry.

Consider in detail each type.

Rack mount

This beer cooler, as the name implies, is permanently placed under the bar. By configuration, devices of this type are horizontal and vertical. Their advantages:

- high productivity (up to 350 l per hour);

- the ability to simultaneously cool up to 20 beers;

- high power;

- remaining free space on the bar counter.

A drawback of rack-mounted coolers is their impressive size.

It is reasonable to use such units in establishments where large volumes of beer are bottled, and not just one, but several types.

The principle of their work is unusually simple. Beer is stored in kegs at a temperature that is maintained indoors. Through hoses, it enters the cooler, and from there to the pouring column, where there is a special lever (crane). When you click on it, the drink begins to pour into the glass.

On the market you can find many models of rack-mount coolers from different manufacturers. In the price category, the most attractive Chinese devices, but, according to consumer reviews, they do not have high enough quality. Among the relatively inexpensive, but well-proven coolers - brands "Nord", "Amber", "Typhoon", "Pegasus", "Umka".

Superstructure

Beer cooler of this type is placed directly on the bar.

Its advantages:

- compactness;

- the absence of a casting column as unnecessary (in some models of installations for beauty it is preserved);

- quick and easy installation.

The disadvantage is low productivity and power, therefore, rack coolers are wiser to use where beer is sold in a small assortment (up to 4 varieties) and in small quantities (up to 50 liters per hour).

Flowing

To date, the most popular instant beer cooler. The photo shows its design, which includes two main components - the compressor part and a bath with water. In the first part there are a compressor (it is numbered 1 in the diagram), a fan (No. 2), a condenser (No. 9), freon conduits (No. 10) and a throttle (No. 11). The bath contains coils with beer (No. 6), an evaporator (No. 7), an ice bank (No. 8), a stirrer pump (No. 3) and a post-cooling line (No. 4). This element is very important, as beer in hoses that comes out of the cooler bath can have time to heat up significantly before it gets into the glass, which is especially important when the cooler is placed at a considerable distance (more than 3 meters) from the place of bottling. In such cases, sufficient insulation of the hoses with beer is required, plus an additional cooling device. If you neglect this, the client will receive a drink not only not cold enough, but also with a lot of foam. The principle of operation of flow-type devices is to cool the drink with constantly circulating water, refrigerant or ice.

Operating principle

It is not difficult to assemble a flowing beer cooler. The instruction says that for this it is necessary to install a compressor, a fan, a condenser on the carrier platform of the unit, and then connect them with copper tubes by soldering. For greater reliability, these locations should be located outside the bathtub. Next, the cooler is charged with refrigerant and the unit passes a test, the indicator of which is the temperature of the beer during bottling.

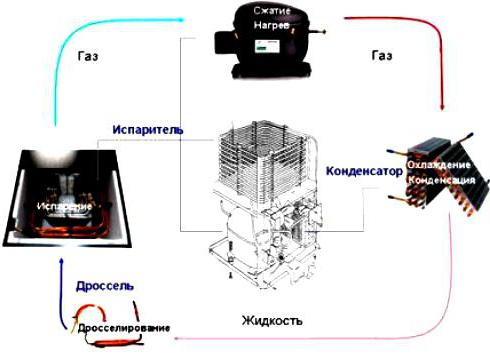

The principle of operation of the device is as follows: the refrigerant (for example, freon) enters the compressor, where it is strongly compressed (pressure increases from 5 to 25 atmospheres). In doing so, it heats up to approximately 80 ° C. Such hot gas enters a condenser continuously blown by a fan. Due to this, the refrigerant cools and turns into a liquid state. At the next stage, he moves into a throttling device (a special tube called a capillary). After it, the pressure of the refrigerant drops due to an increase in the diameter of the french pipe. The temperature of the refrigerant also drops, and it begins to turn into a gaseous state. In this form, it enters the evaporator, where due to the conversion from liquid to steam, it cools the water washing the coils with beer. Having completed his mission, Freon again enters the compressor.

Advantages of flow coolers:

- reliability;

- effectiveness;

- simplicity in installation;

- low price;

- the quality of beer does not deteriorate (there is no oversaturation with carbon).

Disadvantages:

- it is impossible to regulate the temperature of the drink at the outlet;

- too long (up to 5 hours) preparatory stage;

- the need to periodically change the water in the bathroom.

Dry

In recent years, dry-type beer coolers are becoming more popular. Their obvious advantages are:

- compactness;

- quick cooling of the drink;

- short duration (in just 15-25 minutes) preparation for the start of work;

- noiseless process.

The disadvantages include:

- higher cost than flow coolers;

- increased energy costs;

- the impossibility of creating an ice bank.

Device and principle of operation

Dry coolers work in much the same way as flow coolers, so their design is not much different. The main difference is that in these units metal is used instead of water, most often aluminum alloys. This is clearly demonstrated by the above diagram, where the number 8 is a metal block.

Heat transfer in dry coolers is direct, that is, the entire power of the unit is directed directly to the beer in the coils. A design feature of units of this type is the connection of a beer cooler without the ability to connect a post-cooling circuit. Therefore, it is advisable to use such an apparatus where the drink is sold in small volumes, plus the bottling point is next to the cooler itself.

Beer cooler "Typhoon"

Let us consider this brand in more detail, since it is an undeniable leader among analogues. Typhoon coolers are manufactured by the manufacturer of the UBC Group. It is important that the company is not only developing new models of refrigeration equipment, but also sells its products directly, without intermediaries, which allows you to set prices without unnecessary markups. Typhoon beer coolers are available in several models, depending on the volume of beer in liters that the unit can cool in an hour. Among them, Typhoon 50 is the most compact instant beer cooler. The characteristics of the apparatus are as follows: it has a cubic shape, length and width 45, and height 50 cm. At the same time, the mass of the unit is only 33 kg (without water), and at the same time it can cool 2 beers. The most powerful in this series is the Typhoon 220. It is capable of simultaneously cooling up to 14 beers, but it takes at least 6.5 hours to prepare for work. In addition to these two models, the company produces "Typhoons" with a capacity of 75, 90, 120 and 160 liters of drink per hour. Depending on the model, these coolers can be used both in large stationary premises and in small outlets selling draft beer.

Errors in the operation of coolers

Practice shows that, following the instructions, the equipment lasts long enough. The most common errors are:

- The instant beer cooler is put into operation without water in the bath.

- The unit is too compact, that is, the distance from its walls to other objects is less than 150 mm (because of this there is no air circulation, so the cooler overheats).

- The design mode, according to which the thermostat should work, is not observed, which is why the beer is supercooled. This mistake is often made by personnel, wanting to increase the performance of the unit at peak loads. This can cause only foam to flow from the faucet.

There are also a number of purely technical errors associated with improper grounding, improperly selected extension cords, and not sanitizing equipment.

In order to avoid problems when selling beer, you need to strictly follow the instructions attached to each model of cooler.