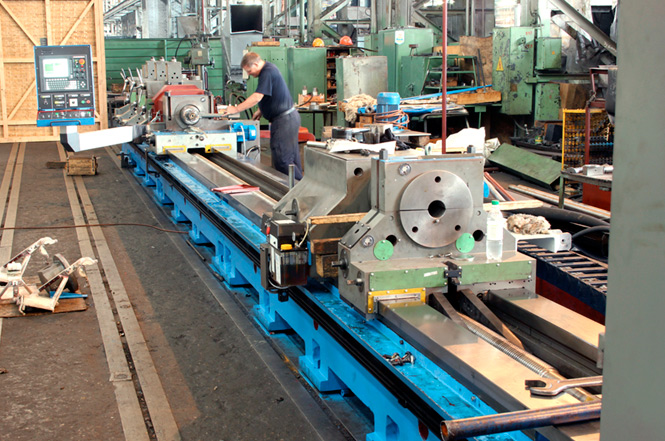

Ryazan Machine Tool Plant (RSZ) is the largest specialized enterprise in the post-Soviet space for the manufacture of metal-cutting equipment and machine tools (including large ones) for various purposes. It is the most important city-forming industrial enterprise of Ryazan.

Description

The construction of the Ryazan Machine Tool Plant began in 1944, and the first product was released four years later. Today, the enterprise is spread over 52 hectares, about 3,000 workers work in its walls. Here, for the first time in the Soviet Union, a CNC machine was designed using domestic components. For almost 70 years of successful work in the RSZ workshops, more than 160,000 machine tools have been assembled, 30,000 of which are with numerical software, which were supplied to 80 countries.

History reference

The Ryazan Machine Tool Plant was one of the first post-war industries built with the goal of speedy recovery of the Soviet economy. It is based on captured equipment repatriated from defeated Germany. German machines were delivered to Ryazan in 508 cars at the site of the enterprise under construction. In 1946, they completed their commissioning, and from 1949 they began to produce turning and screw-cutting metal-cutting complexes.

Near Ryazan machine-tool plant, the village of Prioksky grew up, today it is a large municipal formation, which became part of Ryazan. In 1960-1980, the RSZ assortment consisted mainly of general-purpose metal-cutting equipment for a screw-cutting group. Revolutionary for the domestic industry was the development of its own unique CNC machines, which allowed to increase productivity simultaneously with improved processing accuracy.

In the early 1990s, the enterprise was transformed into OJSC Ryazan Machine Tool Plant. In 2000, a change of ownership took place, and the RosStanKom PG came to production management. RSZ has become the base enterprise of the machine-tool holding. Today, the plant works with all sectors except woodworking. This includes the energy and aviation industries, and railway transport, and oil and gas production.

Quality

In 2003, production at the Ryazan Machine Tool Plant in Ryazan was certified according to ISO 9001: 2000 standards in accordance with international requirements. The company developed a coherent management scheme, changed and adjusted the organization structure in order to optimize costs. Within the framework of the enterprise, the issue of quality assurance was put in the priority direction. The best workers were given personal stigmas. Therefore, situations of claims by operators are quickly resolved. The heads of the workshops were also assigned a part of the responsibility for the manufactured products.

The technological process is structured so that the machines of the Ryazan machine-tool plant are manufactured according to the full production cycle: from casting cases and beds to painting and finishing. No wonder the main slogan of the plant says: "Your consumer is the manufacturer of the next operation." It emphasizes the norm of responsibility of workers between workshops for manufactured equipment.

Lathe machines

Ryazan Machine Tool Plant mastered the production of a wide range of metalworking machines :

- Screw-cutting turning.

- Special turning.

- Heavy turning, including those providing processing of the necks of turbine rotors: special screw-cutting turning, with an operational control system, special turning.

CNC machines:

- Cartridge-center with CNC.

- Cartridge-center turning.

- A series of semiautomatic devices for complex metalworking of shafts and flanges.

- Special CNC semi-automatic lathes.

Machines for railway transport

They occupy an important place in the volume of production:

- Wheel drive checkpoints.

- Special turning.

- Wheel-driven hydrocopy.

- Wheel turning with CNC.

- Special for processing nadressornoj beams.

- Mobile block for processing a thrust bearing.

- Banding.

- Banding.

- Special wheelset.

- Rail-mounted wheel-driven CNC.

Specialized machines

Pipe processing:

- Special pipe-threading.

- CNC pipe-thread turning.

- Special pipe cutting with pipe rotation.

- Special pipe cutting without pipe rotation.

For processing valves:

- Special boring.

- Special grinding and finishing.

- Special equipment.

For deep hole processing:

- Drilling and boring.

- Special honing.

Machines for various purposes:

- Special rollers.

- With an operational management system.

- Hydraulic thread rolling.

- Special CNC turning.

- Special CNC turning for the manufacture of films by transverse turning.

- Technological installation for cold rolling of parts of complex shape.

Foundry

RSZ has a powerful foundry. Although significant volumes of casting are used by the plant for casting machine cases, the team has the opportunity to supply castings (or to make products to order) for other companies. Among the regular consumers of foundry products, such enterprises as:

- Gomel plant of machine components.

- Instrument Plant (Ryazan).

- "Stan Samara."

- Srednevolzhsky machine-tool plant (Samara).

- Samara pump factory.

- SKB ZTS (Kolomna).

- Uralmash Commerce (Yekaterinburg).

- "ShlifMash" (Minsk).

- ZAO ZFS (N. Novgorod).

- Komsomolets OJSC (Egorievsk).

- Bevers (Berdichev).

Some machines are exported to foreign partners.