Tungsten is a chemical element of the periodic system of Mendeleev, which belongs to group VI. In nature, tungsten is found as a mixture of five isotopes. In its usual form and under ordinary conditions, it is a silver-gray solid metal. It is also the most refractory of all metals.

The main properties of tungsten

Tungsten is a metal with remarkable physical and chemical properties. In almost all branches of modern production, tungsten is used. Its formula is usually expressed as the designation of metal oxide - WO 3 . Tungsten is considered the most refractory of metals. It is assumed that only siborgium can be even more refractory. But for the time being, this cannot be precisely confirmed, since the seaborgium has a very short time of existence.

This metal has special physical and chemical properties. Tungsten has a density of 19300 kg / m 3 , its melting point is 3410 ° C. According to this parameter, it takes the second place after carbon - graphite or diamond. In nature, tungsten occurs in the form of five stable isotopes. Their mass numbers are in the range from 180 to 186. Tungsten has a 6th valency, and in compounds it can be 0, 2, 3, 4 and 5. The metal also has a fairly high level of thermal conductivity. For tungsten, this figure is 163 W / (m * deg). In this property, it exceeds even compounds such as aluminum alloys. The mass of tungsten is due to its density, which is equal to 19 kg / m 3 . The oxidation state of tungsten ranges from +2 to +6. In the highest degrees of its oxidation, the metal has acidic properties, and in the lower - basic.

Moreover, alloys of lower tungsten compounds are considered unstable. The most persistent are compounds with a degree of +6. They exhibit the chemical properties most characteristic of the metal. Tungsten has the property of easily forming complexes. But metallic tungsten is usually very resistant. It begins to interact with oxygen only at a temperature of +400 ° C. The tungsten crystal lattice is a cubic body-centered type.

Interactions with other chemicals

If you mix tungsten with dry fluorine, you can get a compound called "hexafluoride", which melts already at a temperature of 2.5 ° C, and boils at 19.5 ° C. A similar substance is obtained by combining tungsten with chlorine. But for such a reaction, a sufficiently high temperature is needed - about 600 ° C. However, the substance easily resists the destructive action of water and practically does not undergo changes in the cold. Tungsten is a metal that without oxygen does not produce a reaction of dissolution in alkalis. However, it is readily soluble in a mixture of HNO 3 and HF. The most important chemical compounds of tungsten are its trioxide WO 3 , 2 WO 4 - tungsten acid, and its derivatives - tungstate salts.

Some chemical properties of tungsten with reaction equations can be considered. For example, the formula is WO 3 + 3H 2 = W + 3H 2 O. In it, the tungsten metal is reduced from oxide, and its property of interaction with hydrogen is manifested. This equation reflects the process of obtaining tungsten from its trioxide. The following formula denotes such a property as the practical insolubility of tungsten in acids: W + 2HNO3 + 6HF = WF6 + 2NO + 4H2O. One of the most remarkable substances containing tungsten is carbonyl. It produces dense and ultra-thin coatings of pure tungsten.

Discovery story

Tungsten is a metal that gets its name from the Latin language. Translated, this word means "wolf foam." Such an unusual name appeared due to the behavior of the metal. Accompanying the mined tin ore, tungsten interfered with the release of tin. Because of it, only slags formed in the smelting process. It was said of this metal that it "eats tin, like a wolf eats a sheep." For many, it is interesting who discovered the chemical element tungsten?

This scientific discovery was made simultaneously in two places by different scientists, independently of each other. In 1781, a chemist from Sweden Scheele received the so-called "heavy stone", conducting experiments with nitric acid and scheelite. In 1783, chemical brothers from Spain by the name of Eluard also announced the discovery of a new element. More precisely, they discovered tungsten oxide dissolved in ammonia.

Alloys with other metals

Currently, single-phase and multiphase tungsten alloys are distinguished. They contain one or more extraneous elements. The most famous compound is an alloy of tungsten and molybdenum. The addition of molybdenum gives tungsten tensile strength. Compounds of tungsten with titanium, hafnium, zirconium also belong to the category of single-phase alloys. Rhenium gives the greatest ductility to tungsten. However, to practically use such an alloy is a rather labor-intensive process, since rhenium is very difficult to obtain.

Since tungsten is one of the most refractory materials, getting tungsten alloys is not an easy task. When this metal is just starting to boil, others are already moving into a liquid or gas state. But modern scientists know how to get alloys using the electrolysis process. Alloys containing tungsten, nickel and cobalt are used to apply a protective layer to fragile materials.

In the modern metallurgical industry, alloys are also obtained using tungsten powder. Its creation requires special conditions, including the creation of a vacuum environment. Due to some features of the interaction of tungsten with other elements, metallurgists prefer to create alloys not of two-phase characteristics, but using 3, 4 or more components. These alloys are especially strong, but with strict adherence to the formulas. At the slightest deviation of the percentage components, the alloy can turn out to be brittle and unusable.

Tungsten - an element used in technology

Incandescent filaments of ordinary bulbs are made from this metal. As well as tubes for x-ray machines, components of vacuum furnaces, which must be used at extremely high temperatures. Steel, which includes tungsten, has a very high level of strength. Such alloys are used for the manufacture of tools in various fields: for drilling wells, in medicine, engineering.

The main advantage of the combination of steel and tungsten is wear resistance, the unlikely damage. The most famous tungsten alloy in construction is called “win”. Also, this element is widely used in the chemical industry. With its addition, paints and pigments are created. Tungsten oxide 6 has been especially widely used in this field. It is used for the manufacture of tungsten carbides and halides. Another name for this substance is tungsten trioxide. Tungsten oxide 6 is used as a yellow pigment in paints for ceramics and glass products.

What are heavy alloys?

All tungsten-based alloys that have a high density are called heavy. They are obtained only using powder metallurgy methods. Tungsten is always the basis of heavy alloys, where its content can be up to 98%. In addition to this metal, nickel, copper and iron are added to heavy alloys. However, they may include chromium, silver, cobalt, molybdenum. The most popular alloys were VMZH (tungsten - nickel - iron) and VNM (tungsten - nickel - copper). The high density level of such alloys allows them to absorb hazardous gamma radiation. They make flywheels of wheels, electrical contacts, rotors for gyroscopes.

Wolfram carbide

About half of all tungsten is used to produce strong metals, especially tungsten carbide, which has a melting point of 2770 C. Tungsten carbide is a chemical compound that contains an equal number of carbon and tungsten atoms. This alloy has special chemical properties. Tungsten gives it such strength that in this indicator it is twice as superior to steel.

Tungsten carbide is widely used in industry. Cutting items are made from it, which must be very resistant to high temperatures and abrasion. Also from this element are made:

- Parts of aircraft, car engines.

- Details for spaceships.

- Medical surgical instruments used in the field of cavity surgery. Such tools are more expensive than conventional medical steel, but they are more productive.

- Jewelry, especially wedding rings. Such popularity of tungsten is associated with its strength, which for those who are married symbolizes the strength of the relationship, as well as the appearance. The characteristics of tungsten in polished form are such that it retains a mirror-like, brilliant appearance for a very long time.

- Ballpoint pens for luxury pens.

Win - Tungsten Alloy

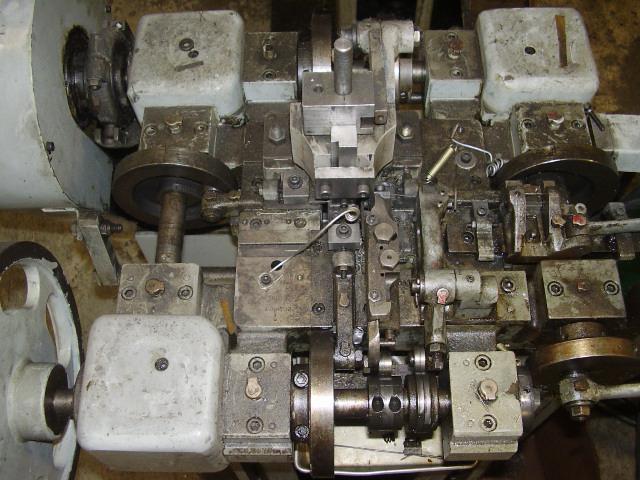

Around the second half of the 1920s, alloys for cutting tools, which were obtained from tungsten carbides and cobalt metal, began to be produced in many countries. In Germany, such an alloy was called vidia, in the United States - carbola. In the Soviet Union, such an alloy was called "win." These alloys turned out to be excellent for processing cast iron products. Pobedit is a ceramic-metal alloy with an extremely high level of strength. It is made in the form of plates of various shapes and sizes.

The winning process of manufacturing is as follows: a tungsten carbide powder is taken, a fine powder of nickel or cobalt, and everything is mixed and pressed in special forms. The plates pressed in this way are subjected to further heat treatment. This gives a very hard alloy. These plates are used not only for cutting cast iron, but also for the manufacture of drilling tools. Pobedite plates are soldered onto the drilling equipment using copper.

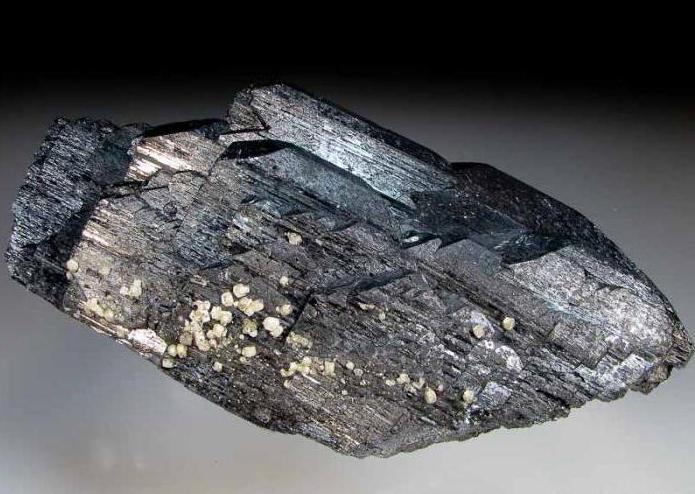

The prevalence of tungsten in nature

This metal is very rare in the environment. After all the elements, it takes 57th place and is contained in the form of a clark of tungsten. Also, the metal forms minerals - scheelite and tungsten. Tungsten migrates to groundwater either in the form of its own ion, or in the form of all kinds of compounds. But its greatest concentration in groundwater is negligible. It amounts to hundredths of a mg / l and practically does not change their chemical properties. Tungsten can also fall into natural bodies of water from the effluents of plants and factories.

Effects on the human body

Tungsten practically does not enter the body with water or food. There may be a danger of inhalation of tungsten particles together with industrial air. However, despite being classified as heavy metals, tungsten is not toxic. Tungsten poisoning occurs only in those associated with tungsten production. Moreover, the degree of influence of metal on the body is different. For example, tungsten powder, tungsten carbide, and a substance such as tungsten anhydrite can cause lung damage. Its main symptoms are general malaise, fever. More severe symptoms occur when poisoning with tungsten alloys. This occurs when the dust of alloys is inhaled and leads to bronchitis, pneumosclerosis.

Metallic tungsten, getting inside the human body, is not absorbed in the intestine and is gradually excreted. Tungsten compounds related to soluble can be of great danger. They are deposited in the spleen, bones and skin. With prolonged exposure to tungsten compounds, symptoms such as brittle nails, peeling of the skin, various dermatitis can occur.

Tungsten reserves in various countries

The largest tungsten resources are in Russia, Canada and China. According to scientists, in the domestic territories there are about 943 thousand tons of this metal. According to these estimates, the vast majority of reserves are located in Southern Siberia and the Far East. The share of explored resources is very insignificant - it is only about 7%.

By the number of explored deposits of tungsten, Russia is second only to China. Most of them are located in the regions of Kabardino-Balkaria and Buryatia. But in these deposits not pure tungsten is mined, but its ores, which also contain molybdenum, gold, bismuth, tellurium, scandium and other substances. Two thirds of the obtained volumes of tungsten from proven sources are contained in refractory ores, where scheelite is the main tungsten-containing mineral. Easy-to-concentrate ores account for only a third of all production. The characteristics of tungsten mined in Russia are lower than abroad. Ores contain a large percentage of tungsten trioxide. In Russia, there are very few alluvial metal deposits. Tungsten sands are also low quality, with lots of oxides.

Tungsten in economics

Global tungsten production began to grow around 2009, when Asian industry began to recover. China remains the largest producer of tungsten. For example, in 2013, the country's production accounted for 81% of the global supply. About 12% of the demand for tungsten is associated with the production of lighting products. According to experts, the use of tungsten in this area will be reduced against the background of the use of LED and fluorescent lamps in both domestic and industrial environments.

It is believed that the demand for tungsten will increase in the production of electronic equipment. The high wear resistance of tungsten and its ability to withstand electricity make this metal the most suitable for the production of voltage regulators. However, in terms of volume, this demand remains rather insignificant, and it is believed that by 2018 it will grow by only 2%. However, according to scientists' forecasts, in the near future there should be an increase in demand for cemented carbide. This is due to an increase in automobile production in the USA, China, Europe, as well as an increase in the mining industry. It is believed that by 2018, demand for tungsten will increase by 3.6%.