Rechargeable batteries are used in many industries, but transport equipment is closest to the mass consumer. And in this sphere weaknesses of such nutrients are most pronounced. Problems in the operation of batteries are caused by the nuances of ergonomics, maintenance and maintaining optimal reliability in different application conditions. At the same time, some of the shortcomings were minimized with the help of Absorbent Glass Mat (AGM) technology in the 1970s. A new approach to the organization of internal space, also associated with changes in the characteristics of the electrolyte, is relevant today. Moreover, the AGM technology has undergone many adjustments over the entire period of its existence and today allows the development of batteries with fundamentally improved qualities. However, such batteries are not spared from the shortcomings.

Technology Overview

The peculiarity of this technology is due to the principles of the content of the so-called bound electrolyte. So, if in classical batteries liquid electrochemical filling is used as an active substance, then a dense electrolyte is used in AGM systems. Accordingly, this provides at least increased vibration protection. In terms of everyday handling of such blocks, many note the convenience and reliability. But these are not all the features that characterize AGM technology. The absorbed electrolyte, which is most often used in such batteries, in itself has a considerable amount of advantages. In practice, use is noted for its resistance to temperature and the ability to withstand a large number of charges. The implementation of the concept of bound electrolyte requires a special device housing and internal filling.

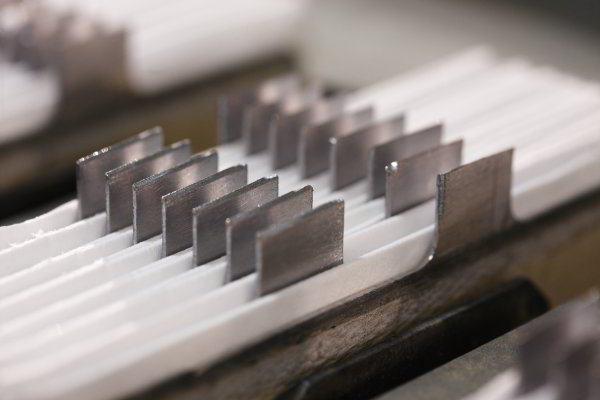

Block design

The case is made of high-strength plastic, which houses a set of electrode plates. As a rule, the latter are made of lead, which makes such constructions related to classic blocks. The main difference lies in the properties of the electrolyte, which is a water-acid solution. This is a kind of acid that fills the body space to ensure subsequent reactions between the electrodes. Actually, the difference is due to the fact that the filling has not a liquid, but a solid state. Typically, manufacturers use microporous fiberglass based material to provide this condition. It is impregnated with electrolyte and thus form a dense bundle between the internal components of the block. The filler also acts as a separator, preventing the solution from spreading. However, AGM technology may provide for other methods of tight bonding of an electrochemical substance, but the essence of the method remains the same - to ensure the reliability of the active element content without losing the basic function of the battery.

Varieties of AGM batteries

Battery models of this type are manufactured in flat or spiral forms. This refers to the arrangement of electrodes. Spiral components are characterized by extensive surface electrochemical contact, which in practice contributes to an increase in the ability to provide high currents for a short time. In addition, many motorists note a quick replenishment of energy potential. But, on the other hand, models with flat electrodes outperform spiral ones due to the balanced specific battery capacity. By the way, gel blocks and traditional lead-acid ones differ in similar qualities. AGM technology only optimizes the planar configuration, allowing in the established format to provide the highest battery performance.

Similarities to GEL Technology

This is a group of gel batteries, which are also being developed in accordance with the concept of bound electrolyte. Only in this case is another principle of viscous filling used. For this, silica gel is used, which completely covers the entire space of the block. Like the AGM technology, the manufacturing technique of GEL batteries provides vibration resistance and the reliability of the electrochemical filling as a whole. In this regard, the main advantage of gel batteries is the elimination of the risk of short circuit. A tight fit to the electrodes does not allow them to collapse with time, and the electrolyte also effectively copes with its function, interacting through the pores of the filler.

According to experts, models of this type can withstand about 1200 charge cycles. Budget devices allow you to recharge the charge 500-600 times. The AGM technology achieves similar performance. The advantages and disadvantages of both designs are generally similar and are in the features of the interaction of electrodes and electrolyte. But there is also a difference in operational nuances, which are noticeable only in practice.

Which is better - AGM or GEL?

To begin with, it is worth emphasizing that gel devices are more expensive than AGM models, although this does not mean their obvious advantage. So, to give preference to structures with absorbed electrolyte is worth those who want to be sure of the resistance of the filling to high power discharges. In addition, such blocks benefit from a quick replenishment of energy reserves. At the same time, AGM and GEL technologies hold the charge approximately equally stable - in any case, if we compare models from the general price group. As for the advantages of gel elements, they perform better under conditions of high loads - for example, after a deep discharge or in the presence of external electrical interference. To this we can add the rigidity of the filler, which does not allow physically destroying the filling, while maintaining the integrity of the same electrode. The gel models in the latest versions are developed to strengthen precisely the strength quality, but progress in this direction is hindered by the inevitable decrease in the electrical properties of the unit.

Technology advantages

If we compare the advantages of the technology against the general background of rechargeable batteries, then the absence of the need for maintenance will come to the fore. Further, one can emphasize the advantage, which applies to all devices made on the basis of a bound electrolyte. It is a valve-tight, sealed design that minimizes the risk of acid leakage. That is, it speaks of the reliability of the unit in terms of physical handling, and its environmental safety. This property, by the way, is characterized by expensive branded batteries, and low-cost models, poorly made. AGM technologies protect the internal filling as much as possible, which also contributes to increasing the efficiency of electrochemical processes. Here again, one can return to a large number of charge cycles, quick replenishment of energy and stable operation of the electrodes.

disadvantages

Most of the minuses that have batteries of this type apply to all lead-acid devices. For example, this applies to heavy weight, to the toxicity of lead oxide, and also to restrictions regarding the organization of storage conditions. In particular, manufacturers do not recommend storing blocks in a discharged state. In addition, contrary to popular belief, experienced motorists note that in conditions of frost, a decrease in performance is manifested. This refers to voltage fluctuation, which usually decreases. Also, many indicate the impossibility of restoring the element after a deep discharge. This is another point where AGM technology is inferior in reliability to GEL designs. However, provided that even the general rules for the use of such batteries are observed, such troubles can be completely avoided.

Battery Guidelines

To prevent battery sulphation, it is recommended that you always maintain their optimum charge. As capacity is lost, the working life of the active elements is reduced. Also, do not allow short circuits in the terminals. Although the developers of AGM-batteries are working hard to improve the reliability and functional parts of the case, it is important to maintain the correctness of the external connection. By the way, this is especially true for operations during which AGM batteries are being repaired. The technologies of manufacturing new generation batteries also increase the mechanical strength of the case, but even taking this aspect into account, one should not rely too much on the durability of the plastic used for the shell. An open AGM battery is no less dangerous than traditional lead-acid blocks.

Technology Applications

Of course, modern batteries with improved performance are not only used in automobiles. Products created on the basis of AGM technologies are used in energy supply systems, public utilities, telecommunications, etc. The possibility of autonomous energy supply is also in demand in medicine - to maintain equipment operability in emergency situations. But, since AGM technology in batteries does not exclude the use of heavy and toxic hazardous metals, manufacturers also impose restrictions on their operation.

Manufacturers

The domestic battery market is saturated with models of various types, including AGM elements. In particular, the initial segment represents products from Ventura, Optima, as well as some modifications from the Stinger line. However, the most high-quality batteries with AGM technology, according to many motorists, are offered by Delta and Warta manufacturers. In addition, in the families of these companies you can find different modifications of the blocks for any request.

How much does an AGM battery cost?

Much depends on the technical characteristics, quality of the materials used and capacity, but on average prices vary from 10 to 20 thousand rubles. The cheapest batteries of this type cost about 5-6 thousand. If you purchase a model for a car demanding on electrical engineering, you can immediately turn to a segment of 20 thousand. That is how much high-quality and reliable AGM batteries cost. The technologies for organizing the content of absorbent electrolyte at this price level manifest themselves most favorably, although they also do not exclude the disadvantages characteristic of the general class.

Conclusion

The emergence of breakthrough technologies in various fields often causes a stir in the market, but over time, everything returns to its mainstream and the consumer still prefers traditional products. This is due to the fact that the developers of new solutions in advertising focus on the merits, not always fully revealing information about the shortcomings. So in this case, but experienced car enthusiasts and just experts are well acquainted with the pluses and minuses that AGM technology gives. Lead batteries, even with a dense electrolyte, do not cease to be sensitive to voltage surges, require the observance of the same safety measures, and at the same time are expensive. Nevertheless, in some cases, this option will fully justify itself. AGM batteries meet the needs of those motorists who focus on the mechanical strength of the battery, its durability and performance. But to maintain these qualities for many years is possible only subject to the rules of battery operation.