Today, there are many different building materials, but all of them have been used for quite some time. Recently, expanded clay blocks have been increasingly used . The thermal conductivity of this material allows you to build residential houses from it, and if you compare it with any other material, then the closest thing to this indicator will be wood.

Block production

Today, many are engaged in the production of such blocks. The difference between manufacturers is usually in the proportions of raw materials, as well as in the possible addition of plasticizers to improve performance. However, it is important to understand that the technological process practically does not change from this, and therefore it can be said with confidence that they all produce this material using the same technology. A change in the composition affects only the thermal conductivity of expanded clay concrete blocks and their other parameters.

Manufacturing process

The first stage is the preparation of all the required components, including cement, expanded clay, water, fillers. All these components are poured into the concrete mixer in the selected proportions, after which they are thoroughly mixed for 2-3 minutes. In this case, cement is the main binder. The thermal conductivity of expanded clay concrete blocks and their other parameters, which will be obtained at the output, depend on the ratio of the proportions of all these substances.

The second stage requires the use of a vibrating machine for molding the material. In order to carry out this process, a steel plate is placed in a special recess of the desired size, onto which the solution is poured. After this, the mixture is compacted using a machine.

The third and final stage of the manufacturing process is the drying of the already rammed mixture. Concrete blocks remain in special plates in which they are dried for two days. After this period, the plates are removed, and drying continues, but already in the open air. To do this, leave them for another 8 days. The result of these actions is expanded clay concrete block. Thermal conductivity is not the only advantage, in addition to it, there are a number of other qualities:

- frost resistance is more than 25 cycles, which is quite a lot;

- moisture absorption is quite small - less than 20%;

- good level of thermal insulation and sound insulation;

- high strength and complete environmental friendliness of the material;

- light weight and long service life;

- The price-quality ratio is quite acceptable.

Marking of the finished product

The coefficient of thermal conductivity of expanded clay concrete block is 0.15-0.35 W / (m * K). It is no coincidence that this parameter has a slight difference, since it depends on the density, that is, on the amount of cement in the block. The more cement there is, the higher this indicator, in addition, the density also increases. It is on this parameter that several major brands of building material are distinguished.

The most popular brands of expanded clay concrete are as follows:

- M50 - used for the construction of partitions and load-bearing walls.

- M75 - is used for the construction of load-bearing walls not only in private, but also in industrial construction.

- M100 is used when pouring screeds.

- M150 and M200 are used for the manufacture of blocks.

Main characteristics

Among the main parameters of the building material, the following stand out:

- Strength of expanded clay block. It is worth noting that this characteristic is highly dependent on the scope of use, and therefore ranges from 5 to 500 kg / cm 2 .

- The volumetric weight of the block also varies greatly with the same parameter. It varies from 350 to 1800 kg / cm 3 .

- The characteristic of thermal conductivity of expanded clay concrete block is one of its main qualities. As mentioned earlier, the numerical indicators of this parameter are in the range 0.15-0.35 W / (m * K). If hollow blocks are used during construction, then the thermal conductivity coefficient can be significantly reduced, which will make the building warmer.

- Resistance to frost is highly dependent on the porosity of the material. The higher this indicator, the less resistance. The minimum indicator is 15 cycles, the maximum is 500 cycles.

- Also, this material is characterized by shrinkage, which is at a level with heavy grades of concrete and is 0.4 mm / m.

- There is also such characteristic as vapor permeability. The indicators are 0.3-0.9 mg / (m * h * Pa). Indicators will increase with the growth of porosity and hollowness.

- Moisture absorption. The maximum moisture absorption is not more than 10% by weight. To reduce this indicator, various plasticizers are added to the solution.

In the end, it is worth adding that, in addition to the separation by parameters and sizes, there is also a classification by design. Distinguish wall expanded clay blocks and partition expanded clay blocks.

Classification of building material

Today, there are standards that provide for certain sizes. For example, for a wall block it is 188 x 190 x 390 mm. If these are blocks for partitions, then they should be 188 x 90 x 390 mm. Such parameters are considered ideal for the rapid construction of a building. When compared with the construction of an object made of brick, expanded clay concrete blocks are 4-5 times ahead of it. In addition, 2–2.2 times less solution is also used for masonry. This saves not only material resources, but also reduces the weight of the wall. As for the mass of the blocks themselves, the wall weighs from 14 to 26 kg, and for partitions - from 8 to 23 kg.

Types of blocks by design

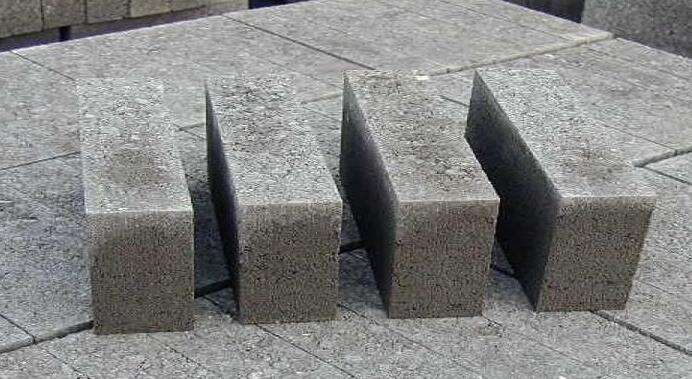

The composition of expanded clay blocks is not the only thing that can differ greatly. This building material may have a different surface. On this basis, ordinary blocks are distinguished, which are used for masonry walls with the subsequent design of their appearance, as well as facial, in which one of the surfaces is front.

In addition, the blocks have voids, because of which they can be either solid or hollow. The first group is more durable elements. The second group is blocks that have either through or tight holes in their structure. Thermal conductivity is quite low for such units, and therefore they are successfully used in cold climates.