Pipe products based on polyvinyl chloride (PVC) today are widely used in a wide variety of fields and industries from the private sector to large oil and gas enterprises. But the process of their consolidation on the market was gradual, since the physical and technical properties of the polymer material are inferior to traditional metal analogues in a number of criteria. Nevertheless, the modern production of PVC pipes through the introduction of advanced technologies has significantly increased the operational characteristics of products in a wide range of evaluation parameters.

Raw material base for production

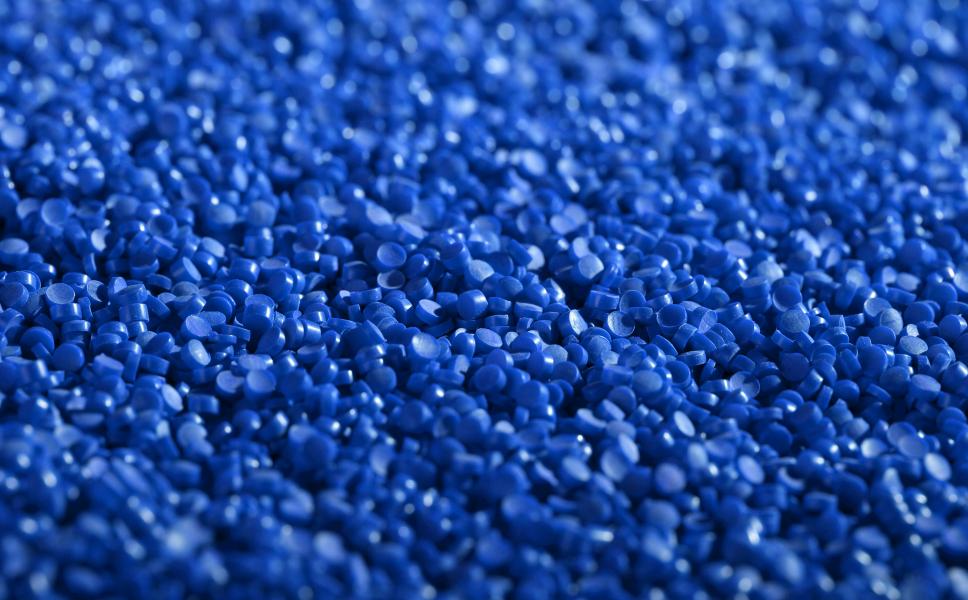

The quality of the final product is largely laid at the stage of selecting the elements that will form the structural basis of the product. It is not always necessary to talk about the need to improve operational properties - for different segments of the application, some qualities are important and others are not necessary. One way or another, the general group of consumables in the manufacture of plastic pipes is polymer raw materials, which are also diverse. Along with polyvinyl chloride, for example, polypropylene and polybutene can be used, but they are often labeled as PVC. For high quality pipes, granular polymers are used - for example, a polypropylene copolymer. Derivatives of such raw materials are characterized by high mechanical resistance and are suitable for communications with high requirements for pressure loads. But raw materials of secondary processing in the form of chemical industry waste can provide decent production results if they are supplemented with reinforcing inclusions based on fiberglass.

PVC-based pipe manufacturing technology

The most developed is the extrusion method, which is also used in the manufacture of plastic bags. Its essence lies in the process of extruding the plastic mass into a predetermined shape under the standard temperature regime. In more detail, the technology for the production of PVC pipes is as follows:

- Sorting and directing raw materials to the receiving hopper of the extruder. The mass entering the processing compartment is crushed and melted under thermal influence.

- Already in molten form, the polymer structure is extruded through a nozzle of a certain format. At this stage, future dimensional parameters and, in general, the configuration of the pipe device are laid.

- Immediately after molding, the workpiece is sent to the cooling zone.

- Under the influence of high pressure, individual characteristics of the pipe are corrected, it is calibrated and final molded.

- Cutting, packaging and labeling. The nature of the implementation of this stage is determined by the requirements for the delivery form.

Extruder device

This is not the only functional unit of production support, but its role in the manufacture of finished products is crucial. At pipe manufacturing plants, extruders are used for continuous processing of raw materials into a single melt with subsequent formation of the product. The feedstock undergoes several technological operations - from the hopper to the hot cylinder for heating and the screw. The most common single screw extruders for plastic, based on the same frame with a vertical gearbox. An asynchronous electric motor, which drives the auger by means of a shaft, is usually used as a source of energy supply. The entire process is controlled by the operator through the remote control. Modern installations are also provided with automation that controls the operations of feeding plastic, heating and extrusion, so the functions of the working personnel can be reduced to general control.

Complete Complete Production Line

On the basis of extruder machines, manufacturers of industrial equipment are trying to create multifunctional lines that support the full range of technological operations. But since structural optimization and the minimum cost of equipment are fundamentally important in this concept, the disadvantages of such a solution in the form of low productivity and sometimes functional limitations are obvious. A full-fledged plastic pipe production line includes several modules, among which the following can be distinguished:

- Machine for the direct manufacture of plastic pipes. It includes the same extruder, as well as a conveyor belt, a heat gun, an automatic mixer of polymer granules, a molding unit in a vacuum, a drive, a cooling system.

- A device for cutting pipes. Typically, carvers support the ability to work with adjustable parameters in accordance with the technical specifications.

- Feed system. A transportation unit that transports raw materials and finished products between technological areas.

- Loader Stacker. Units that perform the functions of automatic storage of finished and cut pipes.

Production By-Products

In large industries, chlorine, hydrogen and caustic soda are inevitably released as a result of the electrolysis operation. However, today this is not a problem, since directly from the places of production of PVC pipes, waste is sent either to landfill sites or to recycling points. In the second case, for example, hydrogen can be used in pyrolysis processes, which can be organized at the same plants of the polymer industry.

Russian manufacturers of PVC-based pipes

Currently, Sayanskkhimplast occupies a leading position in the sector of PVC products in Russia. The production capacity of this plant is about 340 thousand tons. The Bashkir Soda Company (BSK) competes with this company, the potential for the production of polymer products is 220 thousand tons. Among the specialized factories for the production of PVC pipes, one can mention PRO Aqua. This company is engaged in the development and direct production of components for pipes for various purposes - including sewer, water, gas, etc.

Industry development prospects

Russia's petrochemical industry has traditionally lagged behind the foreign participants in the global PVC market in terms of technological development. However, experts expect in the near future an intensive rise in the development of enterprises in this segment, which is associated with an increase in demand for PVC pipes. Production also does not stand still and today they are modernizing in accordance with the new principles of manufacturing products. More modern apparatuses are being introduced to ensure technological processes with plastic, automatic means of control and, as a whole, the configuration of the logistics of plants in the chemical industry is changing.

Conclusion

Obviously, a lot in the development of technologies for manufacturing PVC pipes will depend on the market situation. Active distribution of these products in recent years also does not do without barriers associated with the shortcomings of such products. Another thing is that the modern production of PVC pipes demonstrates an increase in their competitive advantages. It is enough to note the breakthrough associated with the expansion of the scope of pipes with thermally insulated coatings. Also, recently, it was impossible to use plastic pipelines for servicing gaseous media under high pressure, but today this limitation applies only to certain types of products.