The device of the broaching machine is fundamentally different from the equipment that performs the functions of crushing, milling, countersinking and planing. In this case, the method of mechanical action may coincide with the listed processing operations, however, the principle of exerting force in this case is different. In some aspects, the broaching machine provides higher productivity, but the design features do not allow it to be used in enterprises in droves.

General information about broaching machines

The pulling technology, in its principle of mechanical action, corresponds to the traditional and most common types of metalworking equipment. The difference lies in the actual conditions for performing this operation. For example, broaching horizontal machines allow you to accurately process the internal surfaces of various workpieces. This equipment is used to form special chamfers in difficult places.

Often, the operation of stretching in the conditions of continuous mass production is the final stage of manufacturing, following the more familiar types of processing by milling or countersinking. Another feature that distinguishes the broaching machine is the use of specific cutting elements. These are the so-called broaches, which carry out a direct mechanical effect on the material.

Specifications

One of the disadvantages of such machines is considered dimensions. As a rule, this is an elongated platform in which the workpiece is placed. Dimensional characteristics on average are about 2 m in length, 0.5 m in width and 1.5 m in height. However, the configurations can be different - accordingly, the sizes vary. The weight is about 500 kg, so before installation it will not be superfluous to provide a reliable foundation. From the point of view of productivity, the speed of drawing, that is, processing, is also important. For example, a broaching machine from the company Flexible Connections in the modification of SGP.12.35 provides a working pace of 220 mm / min. In other words, in one minute the equipment can cut the inner surface with a length of more than 20 cm. Here it is also worth considering the maximum processing zone, since in most cases the implementation of the same cutting lines in two approaches is technologically unacceptable. The average length of a one-time service varies from 4 to 5 m.

Varieties

Distinguish horizontal, vertical and continuous broaching modifications. The first, already noted option is distinguished by structural simplicity, therefore, it is suitable for performing typical operations on the formation of direct linear cuts with different allowances along the profile. More difficult in its device is a vertical broaching machine. This, in essence, is the same horizontal base, but only installed in a vertical position, which gives several advantages. Firstly, the risk of sagging long broaches is eliminated, and secondly, it becomes possible to increase productivity by expanding the production line. As for machines with continuous extension, they are mainly used for processing through outer surfaces. They are distinguished by higher productivity and the ability to service blanks as part of large-scale manufacturing.

Where is the machine used?

The very specificity of the broaching process determines non-standard requirements for the result obtained. Accordingly, the use of finished products is not the most common. For example, they are used in the manufacture and refinement of firearms. For such operations, planing and broaching machines are used, with which machine guns and pistols are released. Also, this machine is used in the production of complex profiles for exterior decoration, in the cutting of keyways and slots, as well as in the calibration of polyhedral and cylindrical holes. A common feature of all types of lingering machining is precisely the wide possibilities of working with curly cuts, and in difficult conditions. In addition, the machine can be used for both non-metallic and solid-state materials. The fact is that the ability to process atypical workpieces with increased stiffness and hardness is determined by the elements of mechanical action, that is, broaches. And they themselves can have different characteristics.

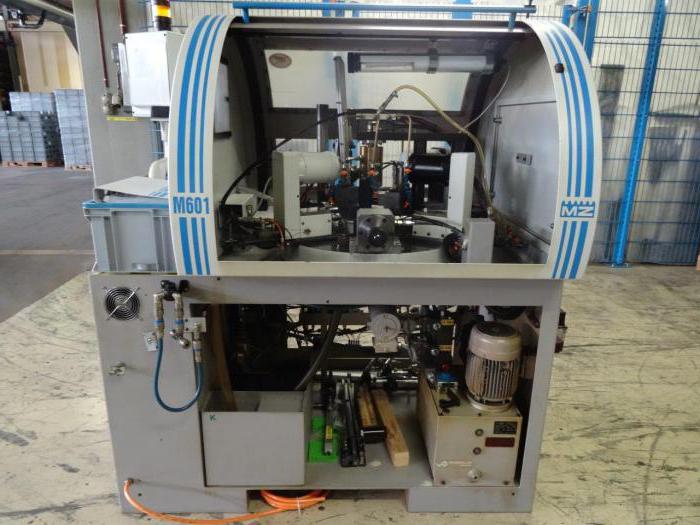

Manufacturers and models

A wide range of products offers the company "Giant". In its assortment, modifications of broaching machines 7A523, 7A612, 7555 and others are presented. The models differ in processing speed, traction, power, dimensions and other characteristics. Among foreign manufacturers, trust has been gained by HOFFMANN Raumtechnik, which is engaged not only in the development of classic models with vertical and horizontal processing lines. In her family you can find specialized broaching machines. Models of the RAWX-M series, for example, are designed specifically for finishing grooving and gear joints. Modification RASA-M is distinguished by the presence of four tracks designed for processing spherical grooves of various couplings. For specialized needs, you can look at a suitable model in the family of the Yaroslavl manufacturer Forst Technologie, which is famous for its meticulous approach to the manufacture of broaching cutting elements of a special design.

Machine cost

The average price range for broaching machines is 2-3 million rubles. In this segment you can find both simple horizontal models and sophisticated modifications of the vertical type. By the way, a vertical broaching machine is more expensive. The price of the 7A612 model from the aforementioned Giant plant, for example, is about 2 million. But this is the lowest price level, since the bulk of the equipment is still sold for 2.5-3 million. This is a high-tech industrial equipment, which is not only characterized by high quality processing but also ergonomic control systems. It is enough to say that the latest models from major manufacturers are increasingly receiving electronic control panels.

Operational Features

The staff is required to place the workpiece in the working niche of the equipment. Further, after starting, the direct processing process begins. A key feature of the operation of such machines is the fact that work items in the form of broaches do not remove chips immediately after trimming, but only push them out after the final exit from the workpiece body. Therefore, the range of tasks of the operator expands due to the need to monitor how correctly machining is performed. On vertical type broaching machines, the risks of deviations and incorrect cutting lines are not so high, since bending of a long workpiece due to its own weight is excluded.

Conclusion

In some areas of the use of metalworking, one can notice similar requirements for performing work operations on broaching and conventional lathes. At the same time, it is obvious that the latter imply less maintenance hassle and are generally cheaper in maintenance. Nevertheless, the broaching machine can justify itself as a universal equipment. If such machines can cope with typical common tasks and with processing for specialized technical tasks, then standard milling units, for example, realize only their limited range of actions. However, broaching equipment also has its limitations, but the segment itself offers very wide processing possibilities - the main thing is to correctly correlate the capabilities of a particular modification with the requirements of technical production tasks.