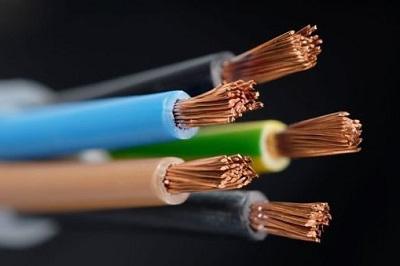

One of the most valuable metals on earth is copper. This is an excellent conductor of electricity and heat, which in these parameters is second only to silver. And copper wire is almost the best material for filigree work. But most of all, it is used in industry as a conductor of electric current. Another copper wire has high ductility. It is also relatively inexpensive and very technological. It can be bent and cut, it is easily amenable to any

type of welding and

soldering, copper wire is available for drawing and rolling. Also, she does not care about both high and low temperatures (from -200 to +250 degrees), and she is not affected by atmospheric and soil moisture. In addition, such a wire is practically harmless and has a long service life. And thanks to these positive qualities they use it very widely.

And an electrotechnical copper wire is made of the same material, whose brand is not lower than M1, and the chemical composition complies with GOST 859-2001. This metal is of sufficiently high quality with a minimum content of impurities (about 0.1%). And the cross section of the M1 wire is round. It is also annealed, and this increases its ductility, and also makes it possible to process it by cutting. And cold deformation gives it high hardness. And for the electrical industry, such wire brands as M1 and M2p are used. And the additional letter "E" in their designation indicates that they require conductivity tests. Also, depending on the hardness of the material, it is still divided into hard MT and soft MM. At the same time, the copper wire of each of these grades has its own advantages and scope. And according to its purpose, it can be divided into electrical, wire for rivets and for low-temperature thermocouples.

And copper wire is used in the electric power industry, construction, printing, mechanical engineering and light industry. Contact wires, cables, rivets, decorative elements and low-temperature pairs are made from it. In the shoe industry, small copper nails, accessories and studs are made from it. And in industries such as engineering, telecommunications and shipbuilding, it is indispensable. Here it is used as windings for electric motors and transformers, spark ignition leads and fuses are drawn from it . At the same time, it is easy to work with it, since it has high plasticity. Even the resistance of copper wire is less than that made of aluminum, moreover, it is stronger. Therefore, it is more profitable to make electric wires out of it, since for the same voltage and current strength, a lighter and thinner wire is required.

Also, copper wires and cable conductors are clad with a metal such as nickel, which has its advantages over tin and silver, especially in some applications of cable products. This is due to the fact that the nickel-plated copper wire is highly resistant to corrosion and oxidation, as well as to extreme temperatures. And it is used mainly in the manufacture of high-quality multicore cables, which are intended for the aviation, electronic, space, telecommunications and defense industries. High temperature cables, spark ignition leads and fuses are also made from copper-nickel wire. It can withstand temperatures reaching up to 750 degrees.