In industries and in the construction industry, non-destructive testing is one of the most popular methods for diagnosing materials. Using this method, builders evaluate the quality of welded joints, check the density in individual sections of structures, identifying deep defects and flaws. Diagnostic magnetic flaw detectors can detect both surface and subsurface damage with a high degree of accuracy.

Device device

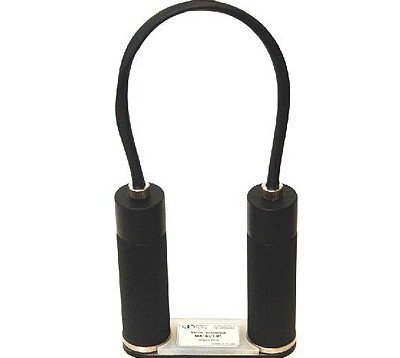

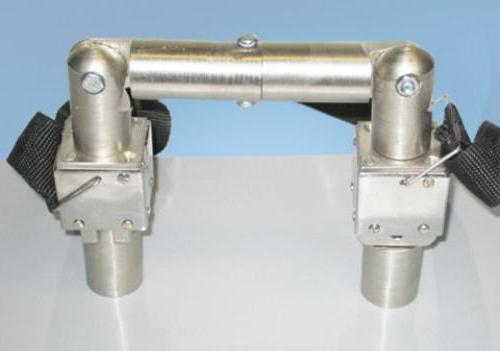

The basis of the segment of magnetic thickness gauges and flaw detectors is represented by hand-held devices provided with magnetized working bodies - usually in the form of ticks. Outwardly, these are small devices, the stuffing of which is an electromagnet that regulates the poles of the wave action. The middle class allows you to work with magnetic permeability, the coefficient of which is higher than 40. The housing is provided with an ergonomic handle, thanks to which the device can be used in hard-to-reach places. To supply electric current, the devices are also provided with a cable connected either to the generator station (if the work is performed on the street) or to a household electrical network of 220 V. More sophisticated non-destructive testing equipment has a fixed base connected to a computer. Such diagnostic tools are more often used to check the quality of manufactured parts in production. They carry out quality control, fixing the smallest deviations from standard indicators.

Fluxgate flaw detectors

A variety of magnetic devices focused on the identification of defects at a depth of 10 mm. In particular, they are used to fix structural discontinuities of structures and parts. It can be sunsets, shells, cracks and hairlines. The flux-gate method is also used to assess the quality of welds. After the end of the working session, magnetic flaw detectors of this type can also determine the demagnetization level of the part as part of a comprehensive diagnosis. In terms of application to parts of different shapes and sizes, the devices have practically no restrictions. But, again, one should not forget about the maximum depth of structure analysis.

Magnetographic and eddy current flaw detectors

Using magnetographic devices, the operator can detect product defects at a depth of 1 to 18 mm. Again, the target signs of deviations in the structure are discontinuities and defects in welded joints. The peculiarities of the eddy current control technique include the analysis of the interaction of the electromagnetic field with the waves generated by the eddy currents that are supplied to the subject of control. Most often, an eddy current flaw detector is used to examine products made of electrically conductive materials. Devices of this type show a high-precision result when analyzing parts with active electrophysical properties, but it is important to consider that they work at a shallow depth of no more than 2 mm. As for the nature of the defects, the eddy current method allows to identify discontinuities and cracks.

Magnetic powder flaw detectors

Such devices also focus primarily on surface defects that can be fixed at a depth of 1.5-2 mm. At the same time, it is possible to research to identify a wide range of defects - from the parameters of the weld to the detection of signs of delamination and microcracks. The principle of operation of such non-destructive testing equipment is based on the activity of powder particles. Under the influence of electric current, they are directed towards the heterogeneity of magnetic oscillations. This allows you to fix the surface imperfections of the target research object.

The greatest accuracy in determining defective areas by this method will be present if the plane of the defective area forms a 90-degree angle with the direction of magnetic flux. As you deviate from this angle, the sensitivity of the device decreases. In the process of working with such devices, additional tools are also used to fix the parameters of defects. For example, the Magest 01 magnetic flaw detector as standard is provided with a double magnifier and an ultraviolet lamp. That is, a direct determination of a surface flaw is performed by the operator by visual inspection.

Preparation for work

Preparatory activities can be divided into two groups. The first will include the direct preparation of the work surface, and the second - the setup of the device. As for the first part, the part must be cleaned of rust, various kinds of lubricants, oil stains, dirt and dust. Qualitative results can be obtained only on a clean and dry surface. Next, flaw detector setup is performed, in which calibration with verification by standards will be a key step. The latter are samples of materials with defects by which it is possible to evaluate the correctness of the results of the analysis of the device. Also, depending on the model, you can fix the working depth range and sensitivity. These indicators depend on the tasks to identify defects, the characteristics of the material being examined and the capabilities of the apparatus itself. Modern high-tech flaw detectors allow you to perform automatic tuning according to specified parameters.

Magnetization details

The first stage of work operations, during which magnetization of the examined object is carried out. Initially, it is important to correctly determine the direction of flow and the type of magnetization with sensitivity parameters. For example, the powder method allows you to perform pole, circular and combined effects on the part. In particular, circular magnetization is carried out by passing electric current directly through the product, along the main conductor, through the winding or through a separate section of the element with the connection of electrical contactors. In the pole mode, magnetic flaw detectors provide magnetization using coils in a solenoid medium, by means of a portable electromagnet, or by means of permanent magnets. Accordingly, the combined method allows you to combine two methods, connecting additional equipment in the process of magnetization of the workpiece.

Drawing a magnetic indicator

Indicator material is applied to a previously prepared and magnetized surface. It allows you to identify part defects under the influence of an electromagnetic field. It has already been said that powders can be used in this capacity, but some models also work with suspensions. In both cases, it is important to consider the optimal conditions for the use of the device before work. For example, magnetic flaw detector “MD-6” is recommended to be used at temperature conditions from -40 to 50 ° and at air humidity up to 98%. If the conditions meet the requirements for operation, then you can start applying the indicator. The powder is applied throughout the area so that a small coverage of areas not intended for research is provided. This will provide a more accurate picture of the defect. The suspension is applied by spray using a hose or spray. There are also methods for immersing a part in a container with a magnetic indicator mixture. Next, you can go directly to product troubleshooting.

Inspection Details

The operator must wait for the moment when the indicator activity ends, whether it is powder particles or suspension. The product is inspected visually with the aforementioned devices in the form of optical devices. At the same time, the magnifying ability of these devices should not exceed x10. Also, depending on the requirements for the examination, the operator can take pictures already for a more accurate computer analysis. Multifunctional magnetic flaw detectors-stations are equipped with basic equipment for decoding replicas with powder deposits. The drawings obtained during the sorting are subsequently checked against normative samples, which allows us to draw a conclusion on the quality of the product and its acceptability for the intended use.

Conclusion

Flaw detectors are widely used in various fields. But they also have disadvantages that limit their use. Depending on the operating conditions, they can also include requirements for the temperature regime, and in some cases, insufficient accuracy. As a universal means of control, experts recommend the use of a multi-channel magnetic flaw detector, which is also capable of supporting the function of ultrasonic analysis. The number of channels can reach 32. This means that the device will be able to maintain optimal flaw detection parameters for the same number of diverse tasks. In essence, channels are understood as the number of operating modes focused on certain characteristics of the target material and environmental conditions. Such models are not cheap, but they ensure the correctness of the results in identifying defects of the surface and internal structure of various kinds.