A wide range of instruments is used to measure microclimate parameters. In the domestic sphere, homeowners usually get by with traditional thermometers, and in a professional environment , depending on the tasks, multifunctional stations can also be used. But there is also a layer of specialized devices that are oriented not only to measuring, but also to further processing, registration and documentary evidence of information. Such devices include temperature loggers, which can record other indicators - for example, humidity coefficient and pressure level.

Where are loggers used?

Devices of this type are used in various industries where accurate registration of microclimatic indicators with constant monitoring of their changes is required. Typically, such tasks are faced by enterprises that store or transport products that are sensitive to temperature and humidity. For example, it can be pharmaceutical companies, food industry facilities, agricultural complexes, etc. At enterprises engaged in poultry farming, this technique allows you to control the climate in incubators. As part of production lines, it is important to maintain an optimal balance for the raw materials used in processing, and research organizations record global changes in the environment using the same temperature recorders. Loggers can be used in private households. For example, they are necessary in cases where you need to perform lengthy repair work using building materials that are demanding of temperature conditions.

Logger device

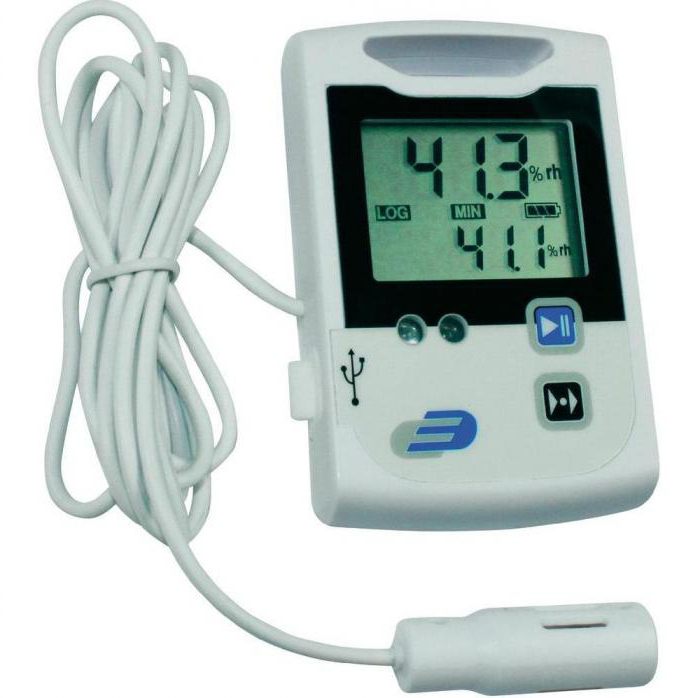

The design may be different, but most often these are compact hand-held or stationary devices. The basis is digital filling with a microprocessor that processes incoming data. It consists of a small case, complemented by a display and controls. An important part of the device is a sensitive element - a kind of sensor that captures the characteristics of the microclimate. From it, data arrives at the processing unit, and then is provided to the user through the screen. At the same time, the temperature logger can also directly transmit information to the target equipment, which, depending on the obtained parameters, automatically adjusts the microclimate parameters in automatic mode and even without operator intervention. In the same incubator, such a device can communicate with a central control unit that regulates the operation of the local heating system. The power supply line of the logger can also be a network power supply line, and batteries with batteries, which ensure the autonomy of the device.

Main characteristics

Like other metrological devices, loggers are primarily characterized by a range of measurements. On average, it ranges from –40 to 90 ° C. In this case, the resolution is approximately 0.5 ° C - this is the step of the metering scale, which, however, may be less depending on the purpose of the model. For example, in highly specialized areas, devices with a resolution of the order of 0.125 ° C are used. From the point of view of quality, an important parameter is the measurement error. This value varies from 0.5 to 1.5 ° C. The wider the overall range of coverage, the lower the accuracy. Unprincipled in terms of quality of work, but essential for ease of use is the volume of the power source in the autonomous temperature logger - again, it can be batteries that need to be replaced after a few months, and a battery that provides performance for 2-3 days until the next charge. During the working process, the device accumulates data in its memory. If it is not planned to connect it with a computer, then the storage capacity will become an important parameter of choice. The minimum memory size is 2048 bytes, and middle and senior models have a reserve of up to 8192 bytes.

Communication support

It has already been noted that the loggers can be connected to a computer and other equipment that processes the data and, in connection with the received information, gives commands to the executive climate equipment. The easiest way to communicate with such components of the system is the USB interface. In this case, a physical communication line is organized that has clear distance limitations. Therefore, the latest models are increasingly used wireless modules. The premium temperature logger can be provided by a radio modem, GSM-receiver or support Wi-Fi technology. A wireless communication method is advantageous in that it makes it possible to place a temperature measuring device in the target area, and leave peripheral equipment, for example, in the control room. And between these points of transmission and reception of the signal will not necessarily lay an additional cable.

Functional Features

An additional set of options can be divided into two types. First of all, these are expanded capabilities for fixing microclimatic parameters, and secondly, operational tools. As for the measurement readings, in addition to temperature, modern models allow you to record humidity and atmospheric pressure data. Moreover, some versions form on the basis of a comprehensive measurement special reports with a histogram and statistics. In terms of operational capabilities, it is worth highlighting the ability of the devices to take into account third-party user information. To do this, temperature and humidity loggers are allocated an additional reserve in memory. This function allows, for example, recording data on current measurement conditions, information about the carrier, methods of further monitoring, etc.

Equipment

In a basic set of deliveries, manufacturers usually provide means for providing communication capabilities. These include adapters, USB wires, remote connectors, and wireless modules. In order to increase the physical usability, loggers for temperature measurement are equipped with special holders and brackets. Using this equipment, the device can be reliably placed in inaccessible places, greenhouses, incubators, transport equipment, etc. Some models also include service kits, which include an assembly tool, test devices, and a software disc.

Device manufacturers

Loggers are produced by large companies specializing in the development of measuring equipment. One of them is the iButton company, which offers functional models with a large capacity for data recording and a long service life. In terms of accuracy and accuracy of providing indicators, the best choice may be the temperature and humidity logger Testo, presented in versions 174T and 176H1. The possibility of using devices in conjunction with programmable controllers is guided by the developers of the domestic companies Aries and Thermochron. The latter, by the way, offers models of the EClerk series, which interact with industrial microcontrollers via wireless communication channels.

What to consider in the choice?

When buying, you should pay attention to both the main operating parameters and ergonomic qualities. It takes into account the same measurement range, accuracy, the amount of data that can be recorded, etc. With regard to technical and ergonomic qualities, the importance of the autonomy and communication means of the device should be noted. In advance, you should calculate the algorithm for the interaction of the device with other equipment. In addition, the temperature logger is selected and taking into account the conditions of its application. So, in an aggressive environment, it is better to use models with a protection class of at least IP65. Cases of such devices reliably protect the filling from moisture, dust and direct heat.

Conclusion

The practice of using loggers shows that their value as indicators of controlling microclimatic parameters is much higher than alternative metrological tools. Even specialized stations are inferior to them in individual operational properties. Moreover, the main advantage of the temperature data logger is not so much in the accuracy and range of measurements as in the post-processing tools. The device precisely prepares the recorded information for further use. This approach saves the operator from unnecessary work on registration of information and generally optimizes the climate control system.