The so-called Danfort anchor, due to its characteristics and ease of manufacture, is one of the most popular solutions among seasoned anglers and outdoor enthusiasts. In accordance with the current rules, any craft must be equipped with a device for holding the vessel. A factory product of this type is a very expensive pleasure. Therefore, most fishermen and owners of boats and yachts prefer to make such things with their own hands. Danforth's anchor drawings are publicly available. And having a welding machine in the garage and several pieces of sheet iron, you can make an anchor that will not be inferior in its characteristics to factory analogues. This article gives a comparative description of the existing types of devices for holding the vessel, gives recommendations for their choice.

Danforth Anchor Historic

The appearance of this type of device was not due to an inventive fisherman, but to the work of a group of scientists commissioned by the United States Navy. They developed several types of anchors, which a special commission of navy officers subjected to severe trials.

Events took place after the Second World War. On an April morning in 1948, a tugboat entered the sea from a naval base near San Francisco, on board of which were representatives of the armed forces, as well as various US shipping organizations. Retreating a sufficient distance from the coast, the ship turned against the current. A series of experiments followed. A dynamometer was attached to the circuit, which allowed to determine the ultimate force that the product can withstand.

Danforth’s anchor was the last to be tested, as he had the least hopes. However, the results were sensational. This design exceeded all expectations. Subsequent tests in various conditions and on different soils showed the unconditional advantage of the Danfort anchor over other types of devices for holding the vessel. Currently, all sea and river vessels are equipped with similar devices.

Design requirements

The anchor must reliably hold the craft on the surface of the water surface, regardless of any difficulties and weather conditions. A good boat holding device can save the life of the entire crew in extreme situations. This indicator is achieved due to a good and thoughtful product design. However, in some cases, the ability of the anchor to hold the boat or yacht is achieved by increasing the mass of the latter. This approach is fundamentally wrong and creates a whole bunch of problems.

Another important requirement is the ability to easily release the device to hold the boat in the event of its engagement.

An important place among the requirements for anchor mechanisms is occupied by compactness and the ability to resist corrosion (especially in sea water).

The importance of each of these requirements should be discussed separately.

The ability to provide significant resistance

Many beginners and inexperienced fishermen mistakenly believe that any weighty blank can be used as an anchor device. This is the deepest error, which they are convinced of when they first enter the water. And after all, what tricks and inventions do they not go to! Heavy stones, reinforcement and so on are used. But all in vain! After the first significant gust of wind, the boat begins to demolish, and the bottom of the reservoir is polluted with various rubbish. After the fuss, the mood drops, strength runs out, and no longer before fishing. For this reason, you must have a normal device to hold the boat. It will also help to avoid an unpleasant audience with the inspector for water transport and the payment of a significant fine.

Minimal effort to select the anchor and to release in the event of engagement, compactness of the device

The unit should weigh a little and be compact. The Danforth anchor satisfies these criteria to the maximum.

Fishermen, and just lovers of boat trips on water transport, very often change their location in search of a "fishing" place. It is hard to imagine how a person will get tired after a cycle of parkings with a heavy stone or any other weighty object.

The anchor is hooked to driftwood or to bulky garbage that is enough at the bottom of domestic reservoirs very often and with enviable regularity. It costs pretty well. And losing it is highly undesirable. That is why the product must be equipped with a device that allows it to be freely and easily released from captivity.

Corrosion Resistance of Anchor

This requirement is important. Anchors from ordinary ferrous metals, especially in aggressive environments (sea water), become unusable very quickly. Such a device, perhaps, will last several years, but at the same time it will have a terrible look. For this reason, small anchors (Danforth and other types) are recommended to be made of stainless steel. High chromium steels are expensive, but worth it.

Some fishermen manage to cover anchors made of steel of ordinary quality with a layer of zinc or even nickel. Such a measure will somewhat delay the destructive corrosion process, but still, over time, rust beetles cover the surface of the product.

Rope requirements

Unlike the requirements directly to the anchors themselves, with a rope everything is quite simple. As such, any synthetic rope is perfect. To hold the boat on the surface of a river or lake, a cable with a diameter of six millimeters is quite enough. However, such a rope will cut the hands when choosing an anchor. Therefore, it is better to use an end with a diameter of at least ten millimeters.

Tools and accessories for the manufacture of devices for holding the vessel at home

The anchor of this design has a relatively uncomplicated design, which makes it possible to make a decent copy in a garage workshop. All that is needed is a set of tools and the necessary materials.

First of all, you need a good and reliable rope of sufficient length. On large vessels, the anchor is held by steel chains, but an ordinary rope is quite suitable for holding a small boat.

You will also need sheet material. It is better if it is a stainless steel, since such an anchor will last much longer. However, on the other hand, stainless steel is less amenable to processing and welding, so the manufacture of a device for holding a boat from this material will take much more time and effort.

You will also need a steel bar (fasteners for the Danforth anchor cable will be made of it), a hollow metal pipe 30 centimeters long.

Manufacturing technology

The first is to bend the wire and form a spindle from it. In order to prevent the spindle from randomly expanding during operation, its ends are welded. This simple solution will allow you to hold parts of the anchor and greatly facilitate further work.

Then, using a welding machine, a bar, a latch are attached and ribs are welded to the legs. These ribs are necessary in order to significantly increase the reliability of the entire structure.

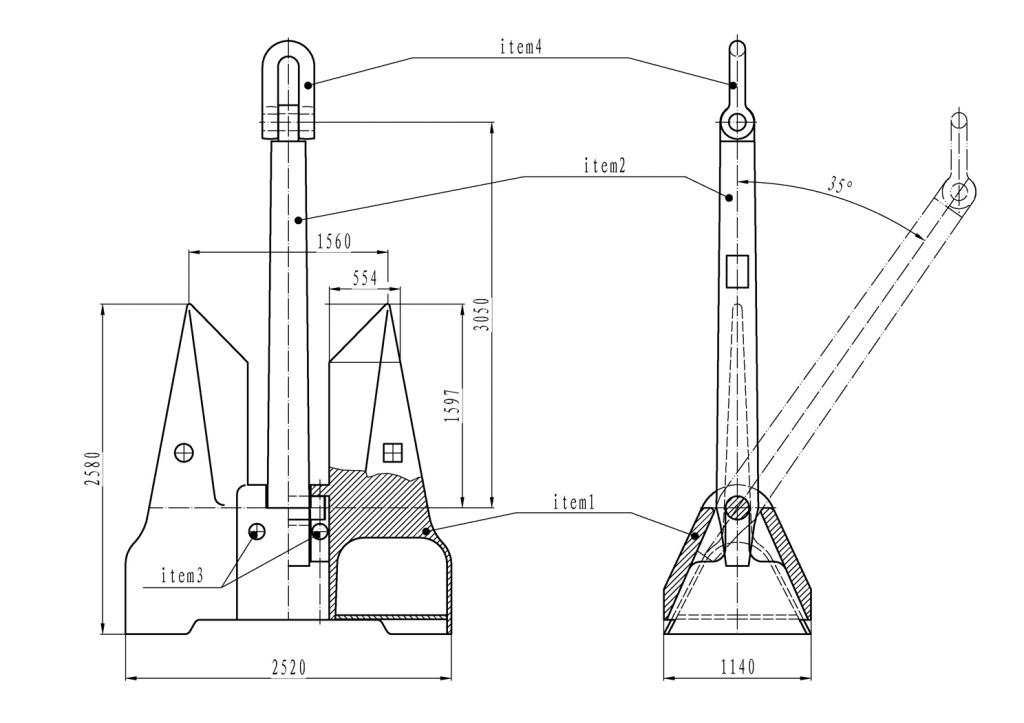

Calculations, geometry and drawings of Danforth Anchor

The designer patented his invention. The document dated 07.15.1941 contains information about the design features and the geometry of the anchor. The main ones are as follows:

- The ideal ratio of parameters is achieved when the area of soil resistance is 60% of the total area of the device. This indicator cannot be less than 40%, since the operational characteristics of such an anchor will be extremely low.

- The slope of the paw of the product may not exceed 75 degrees. Failure to do so will result in the anchor not being held in the ground.

- The angle of attack directly depends on how much of the area of the paws of the product is behind the axis of rotation. In the case when this value is 35% of the surface area of the paws of the anchor or more, the angle can take values from 30 to 50 degrees. If the area of the legs behind the axis of rotation is less than 35% of the area of the legs of the product, the dimensions are set so that the angle of attack is equal to 40-60 degrees. If the anchor is designed to work on hard sandy soil, it should have a minimum acceptable angle of attack (40 degrees). If the device works on a muddy swamp bottom, then the angle of attack increases. This circumstance should be taken into account when designing and manufacturing such devices. If it is not known exactly under what conditions the device will work (manufactured for subsequent implementation), then this figure is usually 50 degrees.

- An important size of Danforth's anchor is the distance between the legs (more precisely, between their centers). When designing and manufacturing such products, it is necessary to strive to ensure that this indicator has a minimum value. This will reduce the value of the emerging pair of forces.

Paw shape

If we analyze the drawings and sizes of Danforth's anchor, then significant differences in the form of lamas and other elements are striking. The geometry of the paws depends on the accepted angle of attack of the soil by the device for holding the boat. The longer they are, the greater the angle of attack. The length of the legs can be from 55 to 70 percent of the length of the anchor spindle. This requirement must be observed if no more than 35 percent of the surface area of the paws is located behind the axis of rotation. If this indicator is greater, then their length can be 55 percent or more.

There is no general consensus regarding the most advantageous shape of the Danforth anchor paws. Responses from boat and boat owners are sometimes conflicting. According to scientific calculations, the most beneficial is the triangular shape. At the same time, thin-walled sheets of strong alloyed with chromium and other alloys of steel grades should be used for their manufacture.

Optimum Stem Length

When manufacturing a product at home, it is very important to choose the correct rod length. The description of Danforth's anchor was compiled by sensible engineers, who paid special attention to this part, realizing its importance.

If the stem is too short, the device does not "bite" into the ground. It simply slides along the bottom when the boat blows away. It is estimated that the length of the rod should be at least two distances between the geometric centers of the paws of the device for holding the boat.

How to use the anchor?

A person who has only recently acquired a boat and is only planning his first sailing out on the sea may erroneously believe that the process of parking is extremely simple. We can say with confidence that such a fisherman will be bewildered. Anchoring is by no means a simple matter, which requires a certain skill, knowledge and knowledge from the fisherman or yachtsman.

First of all, it is necessary to securely fasten the end of the rope to the anchor fixing ring. For these purposes, it is advisable to use a special marine hub. Otherwise, you may lose your device.

Directly near the paws of the anchor there is a second ring. It is necessary to tie a cable with a buoy to it. The length of the cable should be greater than the depth in the parking lot of the boat, otherwise the buoy will sink. This buoy will help to “save” the device in case of breakage of the anchor rope or when hooking on the roots of plants and stones.

Having reached the place where it is planned to make a stop, the holding device is thrown overboard. For a certain time, the boat will be carried away by the current and the wind to the side, until the anchor reaches the bottom and bites into it. Then you can pull the rope.

Design Inadequacies

Any engineering solutions have their drawbacks. You can already notice some flaws in its design from the photo of Danfort's anchor. They should be briefly discussed so that the reader can weigh the pros and cons of choosing a device to hold the boat.

Perhaps one of the main disadvantages of small anchors of this type is their unsuitability for use on a large stone-covered bottom. An attack of such a device on a rocky bottom always remains inconclusive. Small categories of Danforth anchors (4 kg or more) are strongly drifted by the current. Thus, the device drops completely in an unexpected place.

And the reverse side of the coin ... Even a Danforth anchor, insignificant in mass and size, will fix the PVC boat well and reliably if the bottom is soft and muddy. Working only with hands, such a device is quite difficult to tear out. In this case, a small boat will swing very much and may even roll over.