Metal, as one of the most popular building materials, is of serious interest from the point of view of technical and structural development. Its functional qualities expand the possibilities of construction and installation works, allowing you to erect objects with a combination of seemingly contradictory operational characteristics. A striking example of such materials can be called light metal structures (LMK), with the help of which low-rise technical and economic facilities are constructed.

Manufacturing Technology LMK

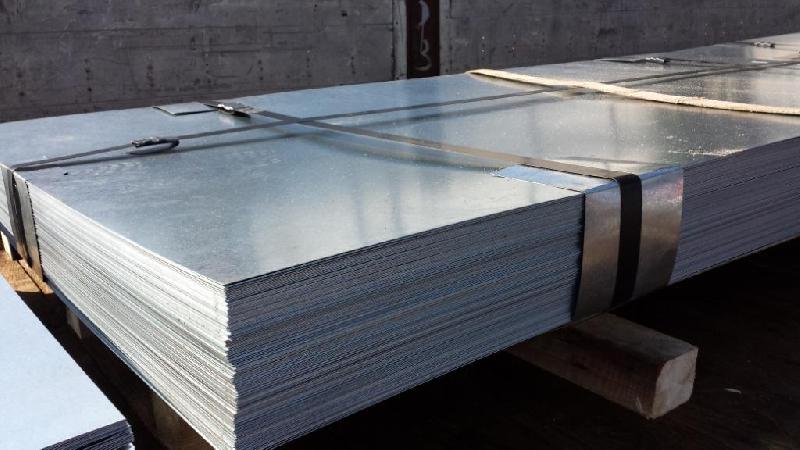

As a raw material for light building metal structures, black metal is used, from which beams, floors, sheet products, stair modules, etc. are produced. Forging, stamping, welding, grinding, cutting, bending and other mechanical and thermal processing of workpieces are used. The practice of using both hot rolling and cold. For example, the Kan factory of light metal structures "Mayak" specializes in cold processing, producing sheet metal, pipes, channels, metal tiles and other products for various needs of industry and construction. No less widely Russian enterprises represented products manufactured using hot rolled processing methods. In this way, products with increased strength and geometric accuracy are obtained. Welding technology also allows you to form complex structures, ready for installation without special modifications at the construction site.

Varieties of light metal

Fundamentally different are ordinary light (LMK) and light thin-walled metal structures, in the manufacture of which only steel is used. Moreover, if the first group of products does not necessarily correspond to the principles of optimization in terms of weight and dimensions, then the second fully fits into this concept. Lightweight thin-walled structures just allow you to build prefabricated frame structures that require minimal financial and physical investment. In the technology of manufacturing thin-walled lightweight metal structures, blanks with a thickness of up to 4 mm are usually used. But this does not mean at all that the manufacturer ignores the requirements for the bearing abilities of the element. By changing the shape of the profile, even thin sheet products can withstand significant loads. In the case of the basic technology for the production of LMK, billets of black metal with a thickness of more than 4 mm are used. Accordingly, in this case, the metal consumption increases and the strength potential of the products increases.

Technical and operational qualities of the material

The specific sets of operational properties and performance indicators depend on many factors, among which the means of final external processing are not the least. The main regulatory qualities of lightweight metal structures include the following:

- Resistance to hostile environment.

- Design flexibility In particular, it provides for the possibility of suspension on load-bearing platforms of hoisting-and-transport units.

- Light weight construction.

- High maintainability.

- Low cost skeleton from LMK.

Installation work with LMK

The advantages of the construction of buildings based on LMK are the complete exclusion of complex technological operations such as welding. Construction is carried out according to the principles of assembly using bolt fasteners and lock joints. In the case of thin-walled steel elements, high-strength self-tapping screws and bolts that withstand static and dynamic loads are used. In critical parts of buildings, the installation of light metal structures can be carried out with the connection of auxiliary elements - for example, stiffening ribs are installed due to profile pipes or frames, increasing the load-bearing capacity of the material. Sheathing can also be done with rivets. Also at the design stage, it is worth considering future opportunities for insulation of structures. Typically, manufacturers design molds with additional fixing parts to integrate mineral wool or foam boards for insulation purposes. LMK is also organically combined with sandwich panels in frameless designs.

Features of the construction of prefabricated objects from LMK

Almost all metal structures made of thin steel are used in the assembly of prefabricated objects. But recently, special home kits with thermal profiles have been developed for this area. Such materials are distinguished by a small cross section with slotted grooves, which increases the volume of passage of warm flows. For the assembly of walls, special elements with enhanced vibro-acoustic characteristics are also used. The set of lightweight metal structures for prefabricated objects also includes steel battens, rafter systems and ceilings with niches, which provide for the laying of communications or the same heat insulator. External cladding with hardware parts is made of galvanized steel and can be supplemented with other claddings.

Scopes of LMK

According to statistics on the use of metal structures, in the world, about 50% of industrial and commercial buildings are constructed from light assortment. In Russia, this ratio fits into 20%. A large proportion of such projects are in complete supply facilities. At the same time, standards for the construction and design of buildings made of lightweight metal structures in the industrial sector were established. As a rule, such structures are up to 18 m high, also providing spans from 18 to 30 m. The loads on the floors in accordance with the standards are in the range from 50 to 140 kg / m2. In addition, the proportion of modular purpose buildings is increasing. On the basis of LMK, kits are being developed for installing service stations, fitness centers, hangars, pavilions, etc.

Conclusion

Lightweight prefabricated structures are designed with a view to future engineering and technological equipment. For warehouses, in this sense, installations ensuring an optimal microclimate are important, and in the organization of production processes, structural possibilities for placing machines and work units come to the fore. These and other nuances of the operation of buildings provide and developers of metal. In particular, the Plant of Light Metal Structures LLC, in addition to directly offering LMK in a wide assortment, also offers integrated infrastructure support for target facilities. This applies to the arrangement of engineering in modular sets of metal structures, originally designed for the organization of lighting, heat and water supply, sewage, etc. For technological facilities, automatic control and mechanization systems are also offered.