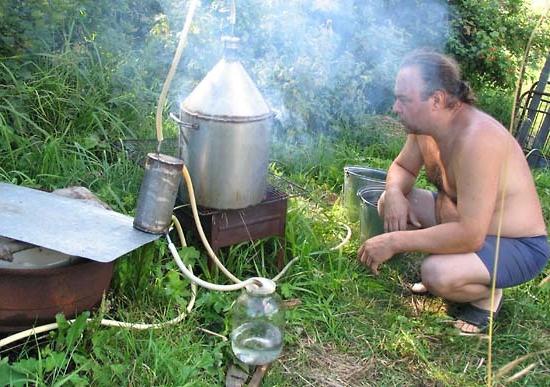

The technology for making moonshine, as a rule, is based on heating the fermented mash to the maximum boiling point and the subsequent cooling of alcohol vapors. In order to prepare a truly high-quality, odorless moonshine, a stepwise heating of the mash is necessary. Let's take a closer look at the process.

A bit about technology

So, first the mash is poured into the apparatus for moonshining for 2/3 of the volume and the process of driving begins. At the first stage, the mash is heated at a high speed. When the temperature reaches 70 degrees, it is desirable to reduce the speed. And when the first distillation appears, it is no longer increased. It is important to ensure that the temperature of the moonshine flowing from the apparatus does not exceed 30 degrees.

Otherwise, the quality of the finished product will be low. In order to get odorless moonshine, you must strictly adhere to the technology. If the resulting moonshine has an excessively high temperature, cooling should be intensified. To do this, simply increase the volume of cold water. In addition to temperature, it is very important to monitor the speed with which the finished product flows out. Experts in the field of moonshining advise to adjust it to the level of 150 drops per minute. A trickle is also possible, the thickness of which should not exceed a match. To maximize the passage of all the moonshine contained in the brew, it is necessary to overtake a third of the original volume of mash. When the temperature of the mash reaches 98 degrees, the distillation process must be stopped.

How many hauls are needed to get a great product

If you follow these recommendations, you will achieve an intense release of fusel oils. To get odorless moonshine, you need to achieve a more concentrated product. To do this, the resulting mixture is distilled repeatedly according to the above technology. Before the second distillation, the moonshine is diluted with soft water. Everything is thoroughly mixed. The second distillation of moonshine is carried out only after a 45-degree concentration is reached.

By the way, the secondary run involves the separation of the product into fractions. So, for example, moonshine of the 1st fraction is obtained at the first stage of the distillation. It is not of good quality. It has a very pungent smell and unpleasant taste. Moonshine of the second fraction is poured into a separate container and used for the preparation of

alcoholic beverages. True, and it requires chemical cleaning. After it, you can get odorless moonshine. Finally, a product that has gone through three stages of distillation is considered a quality product. It turns out to be the purest, has a pleasant smell and not very strong taste. As a rule, it has a low alcohol content (about 10%) and fusel oils are contained in a large volume.

The drink needs to be fixed and can be put on the table. Of course, one cannot know everything about moonshine. The process of its production, despite its apparent simplicity, has a mass of subtleties. It is necessary to drive out not one liter of this product in order to get a really worthy drink, with which you can pamper your relatives and friends. Oh yes, and remember that excessive drinking is fraught with negative health consequences.